326

GEARCASE – STANDARD ROTATION

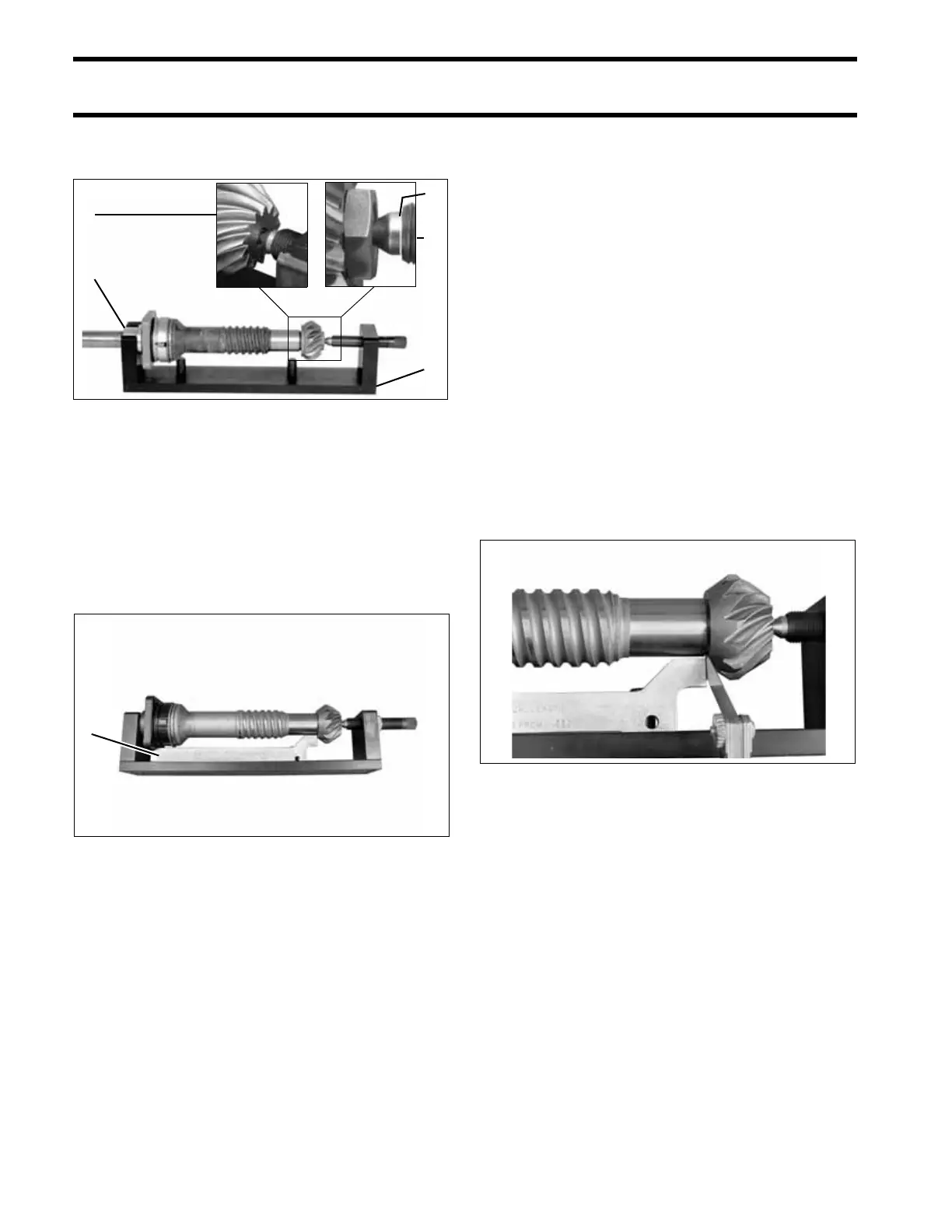

DRIVESHAFT SHIMMING

with end of threads. Tighten locking ring on pre-

load screw.

Rotate the driveshaft several revolutions to seat

bearings.

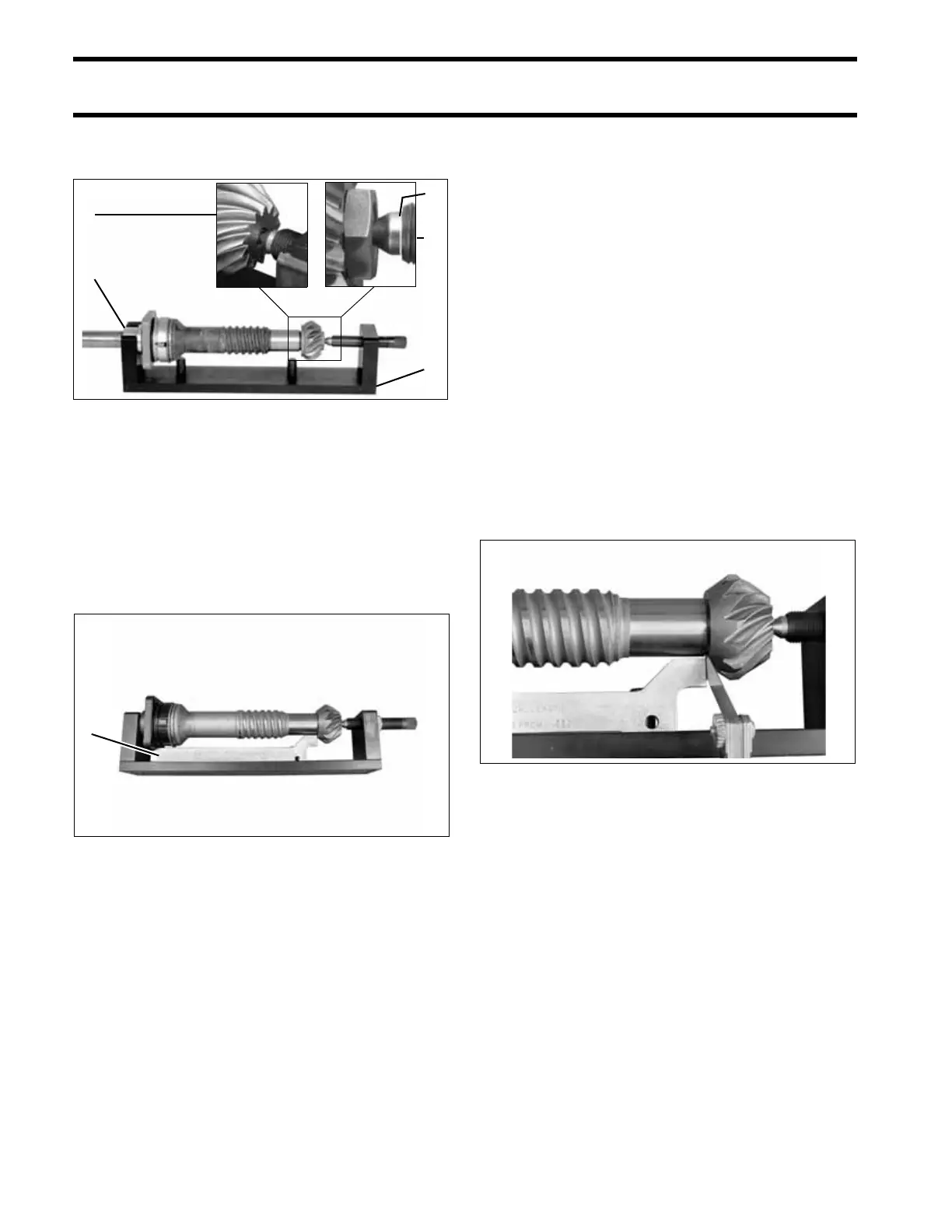

Lay the tool base on its side. Position the shim

gauge bar against guide pins of the tool base.

Check squareness of the bearing housing mount-

ing surface by holding the shim gauge bar against

the pinion while rotating just the bearing hous-

ing. Use a feeler gauge to measure clearance

between the gauge bar and the bearing housing

between each pair of screw holes. Replace the

bearing housing and repeat check if variance is

greater than 0.004 in. (0.010 mm).

Check squareness of the pinion to the driveshaft.

Hold the shim gauge bar against the bearing

housing (between the screw holes) while rotating

just the driveshaft and pinion assembly. Mea-

sure clearance between the gauge bar and the

pinion at several locations. If variance is greater

than 0.002 in. (0.050 mm) replace the pinion or

driveshaft, as necessary, and repeat check.

Subtract the average clearance measurement

from 0.020 in. (0.508 mm) to determine the cor-

rect shim thickness required. Select the fewest

number of shims to achieve the correct thickness.

Remove the driveshaft from the tool and add the

required shims between the bearing housing and

the thrust washer.

IMPORTANT: Use extreme care when remov-

ing bearing housing to avoid damaging the seals.

Use Driveshaft Seal Protector, P/N 318674.

Check clearance again. The measurement

between the gauge bar and pinion should be

0.020 in. (0.508 mm).

“S2” TYPE GEARCASE

Remove the shimming screw and pinion from the

driveshaft.

IMPORTANT: Make sure shimming screw is not

installed in assembled gearcase.

“O”, “L”, “L2”, “M” AND “M2” TYPE

G

EARCASES

Remove the nut and pinion from the driveshaft.

Discard the nut.

1. “S2” Type Gearcase - pinion shimming bolt

2. “O”, “L”, “L2”, “M” and “M2”, Type Gearcases -

pinion nut

3. Collar

4. Tool base

5. Groove

COA3566

DSC00326

005415

1. Shim gauge bar 005416

5

2

4

1

3

1

005417

Loading...

Loading...