237

POWERHEAD

POWERHEAD INSPECTION

11

Crankshaft

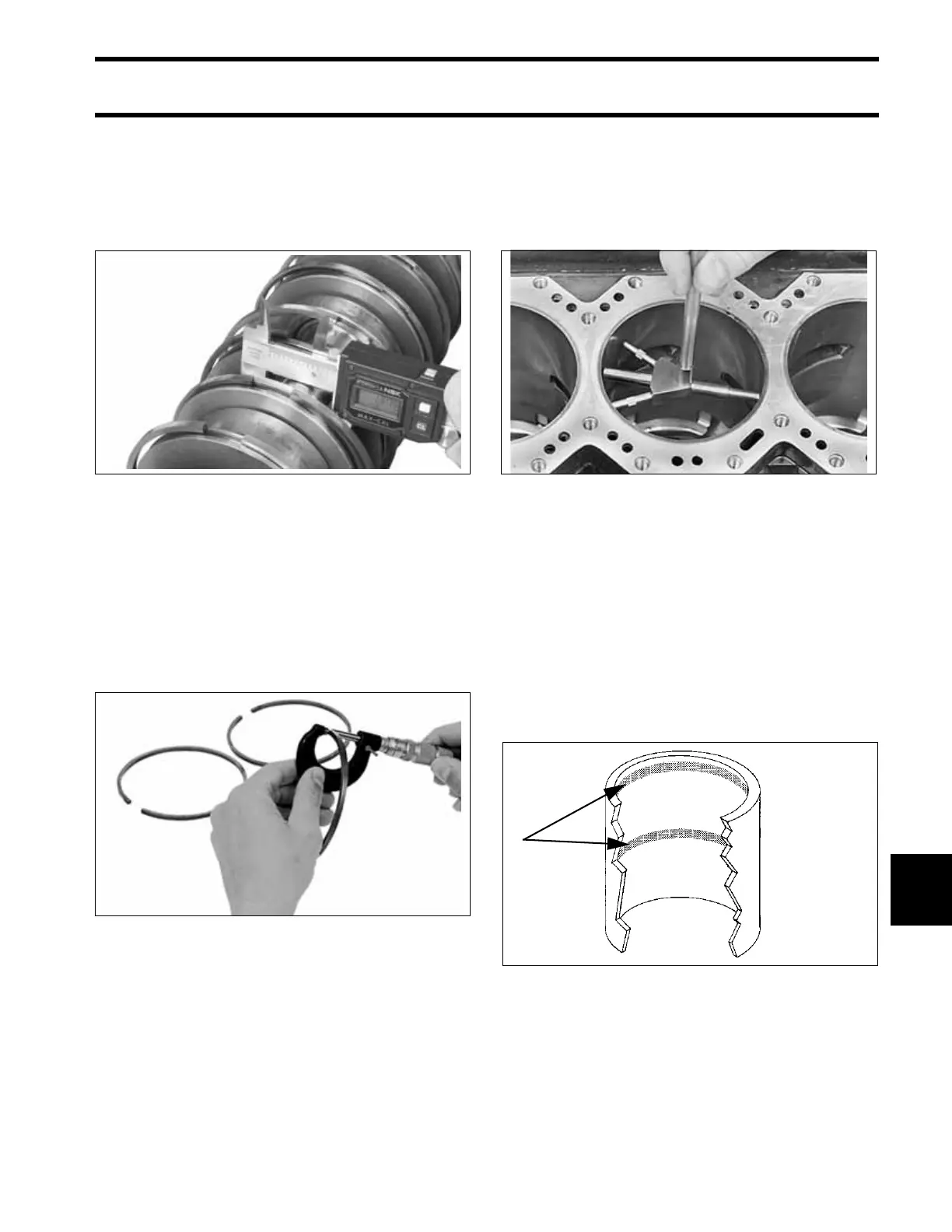

Measure the diameter of each crankpin and main

bearing journal. The lower main bearing journal

would only be measured if the bearing was

removed for another reason.

Visually inspect crankcase seal rings for wear,

grooves, or chipping. If rings appear worn, use a

micrometer to measure ring thickness.

Replace rings that are less than 0.154 in. (3.9

mm) thick.

Install seal rings in their original positions on

crankshaft after inspection.

Cylinder Bore

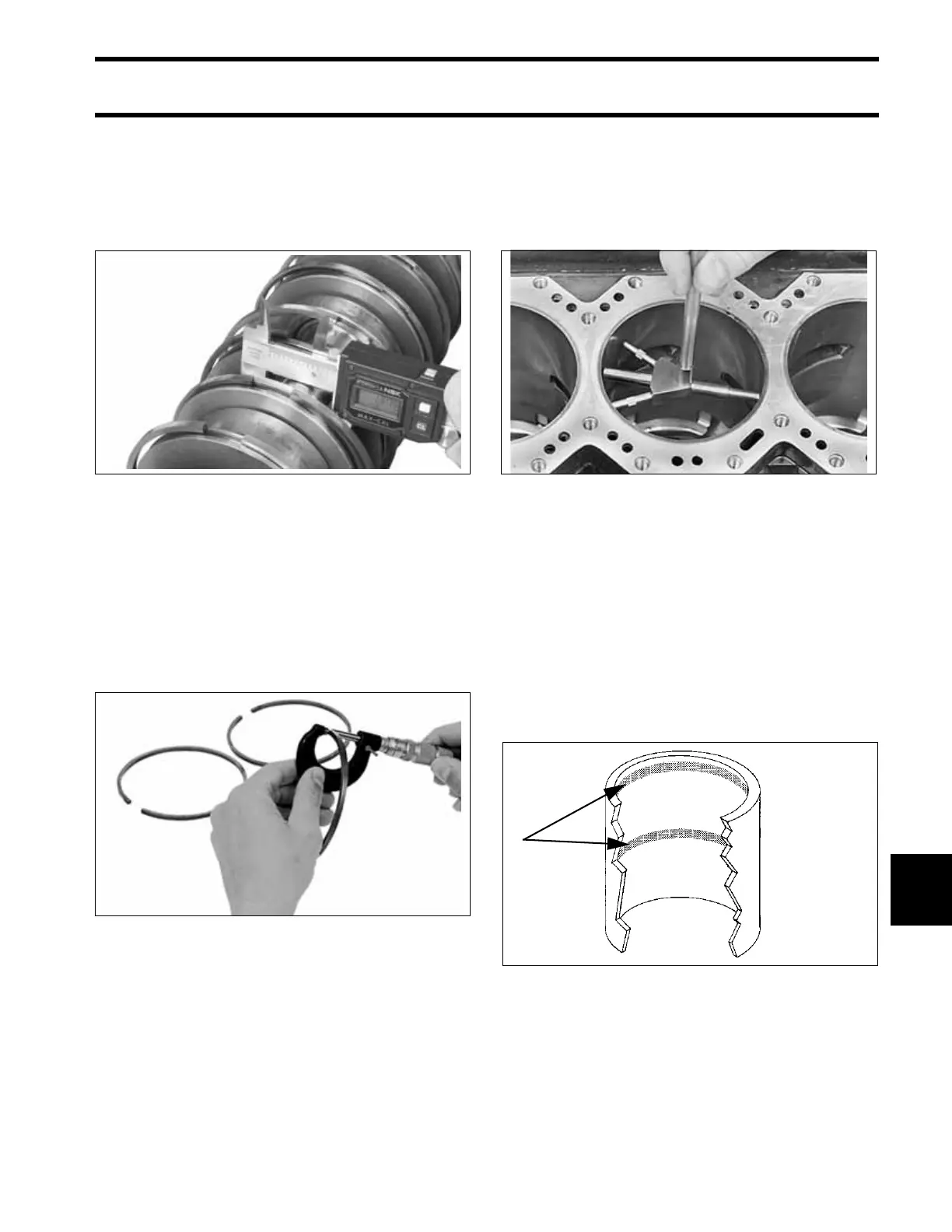

Use Cylinder Bore Gauge, P/N 771310, to inspect

each cylinder bore for an out-of-round, oversize,

or tapered condition. Be sure the gauge is per-

fectly square in the bore when measuring.

Measure each cylinder in at least two areas. Each

area should be measured twice. The difference

between the two measurements in each area is

the cylinder out-of-round dimension.

• The cylinder must not be out-of-round by more

than 0.004 in. (0.10 mm).

The dimensional difference between the two

areas is cylinder taper.

• The cylinder taper must not exceed 0.002 in.

(0.05 mm).

The difference between the measurements and

standard bore is cylinder oversize. For dimen-

sions, refer to SERVICE SPECIFICATIONS on

p. 10.

• The cylinder must not be oversized by more

than 0.004 in. (0.10 mm).

005281

1936

Measure as shown 46528

1. Cylinder taper DR3482

1

Loading...

Loading...