236

POWERHEAD

POWERHEAD INSPECTION

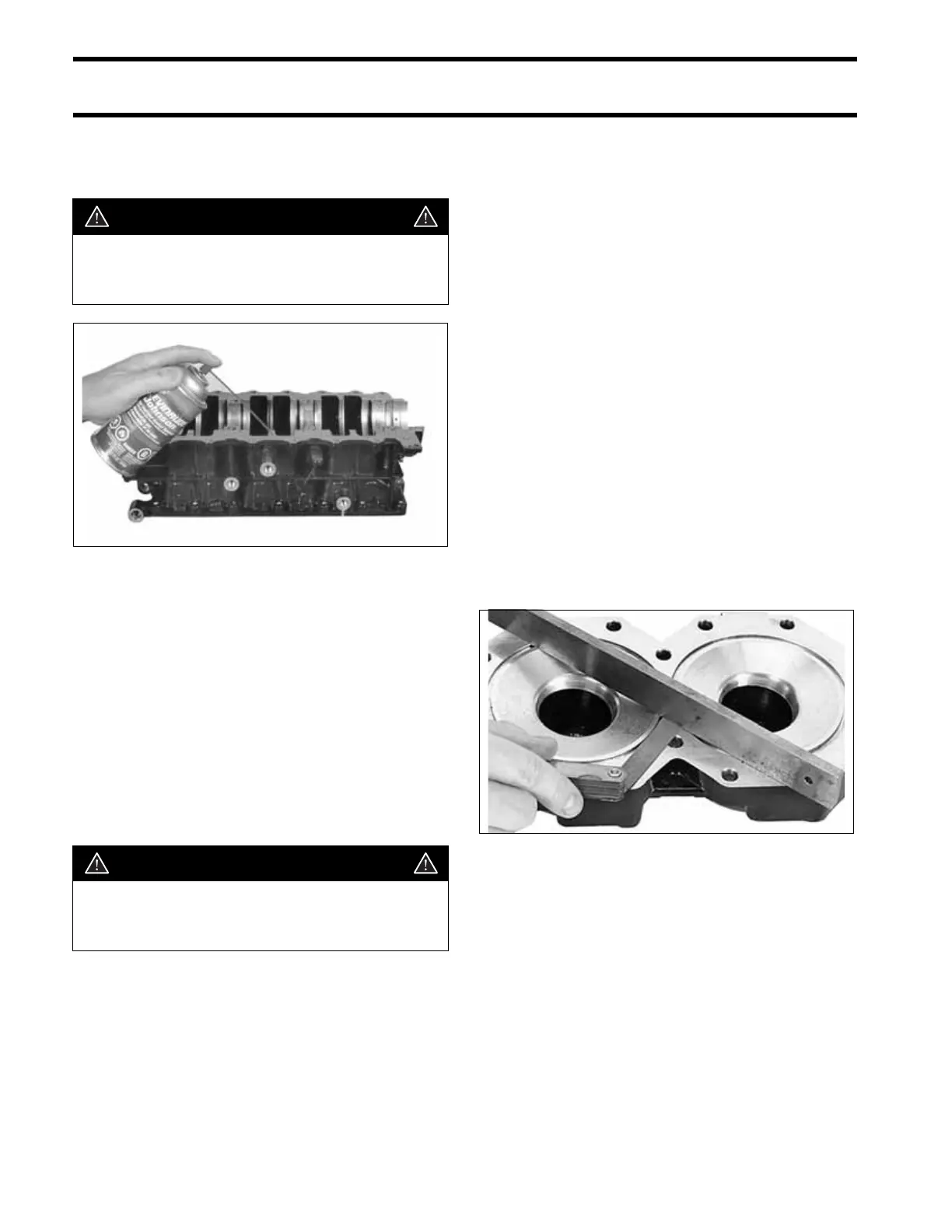

Use Gel Seal and Gasket Remover to remove all

traces of gaskets, adhesives, and Gel-Seal II™

sealant from the cylinder block and crankcase.

Carefully remove any carbon accumulation from

the tops and ring grooves of the piston using

Engine Tuner. A ring groove cleaning tool can be

made by breaking an old ring and grinding an

angle on its end. Do not damage ring grooves

while cleaning.

Thoroughly wash entire cylinder block and crank-

case with warm, soapy water to remove all traces

of contaminants.

Air dry cylinder block and crankcase. Blow all

holes and passageways with compressed air.

Cover the cylinder walls with a liberal amount of

outboard lubricant to prevent corrosion.

POWERHEAD

INSPECTION

For dimensions, refer to SERVICE SPECIFICA-

TIONS on p. 10.

IMPORTANT: Before any inspection process

can begin, all internal components must be com-

pletely clean and free of contaminants.

Visually inspect all parts. Check for unusual wear

patterns, scuffing, or deterioration of aluminum

parts, heat-related discoloration of bearings and

bearing surfaces, and broken components.

Cylinder Head

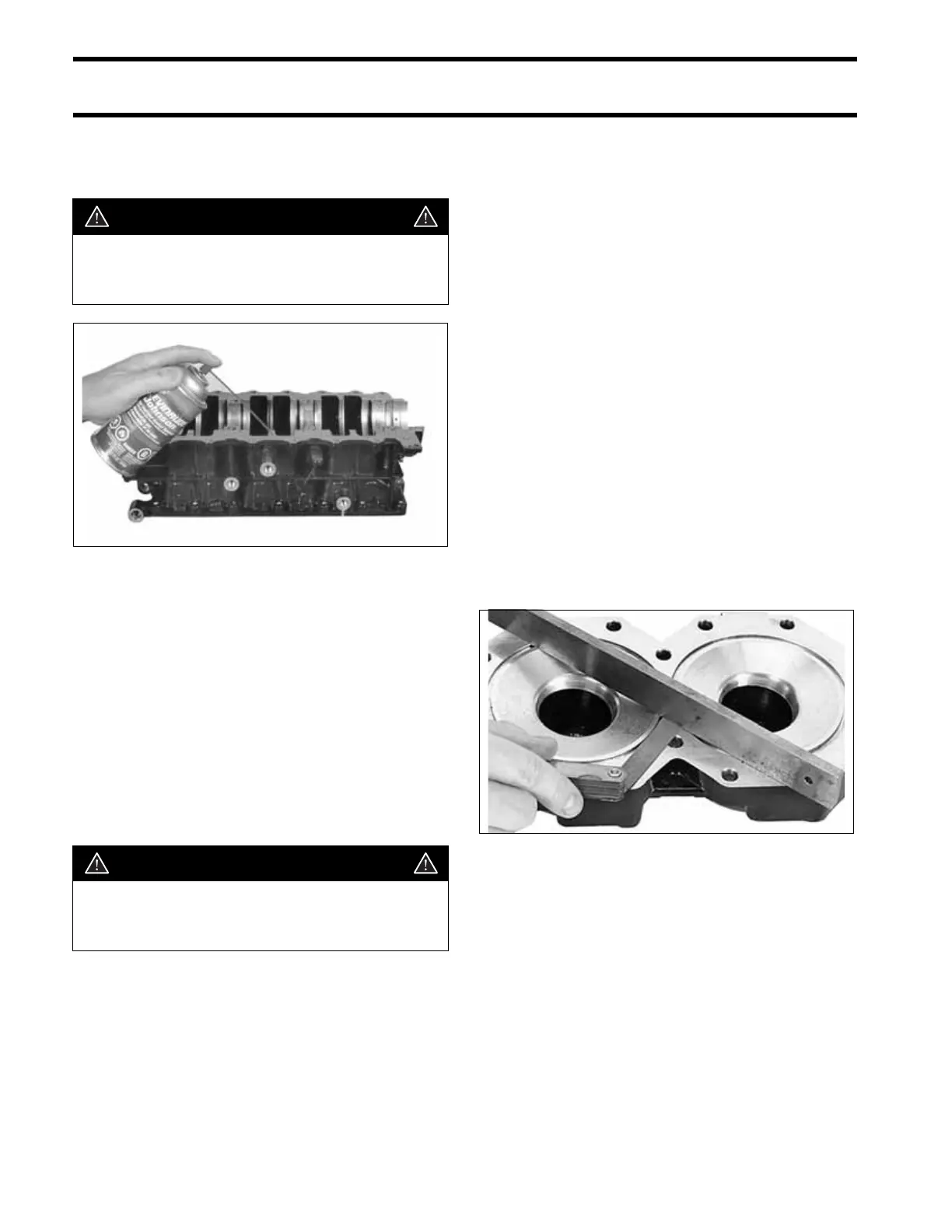

Check for cylinder head warpage using a piece of

bar stock or machinist’s straightedge and a feeler

gauge set.

Cylinder head warpage must not exceed 0.003 in.

(0.08 mm) per inch of measurement. Replace

head if warpage exceeds this dimension.

WARNING

To avoid personal injury, wear eye protec-

tion and rubber gloves when using Gel

Seal and Gasket Remover.

005296

WARNING

To avoid personal injury, wear eye protec-

tion and set compressed air pressure at

less than 25 psi (172 kPa).

46517

Loading...

Loading...