316

GEARCASE – STANDARD ROTATION

GEARCASE HOUSING INSPECTION

GEARCASE HOUSING

INSPECTION

Thoroughly clean gearcase housing to remove all

dirt and debris prior to inspection. Inspect pinion

bearing and forward thrust surface of gearcase

housing.

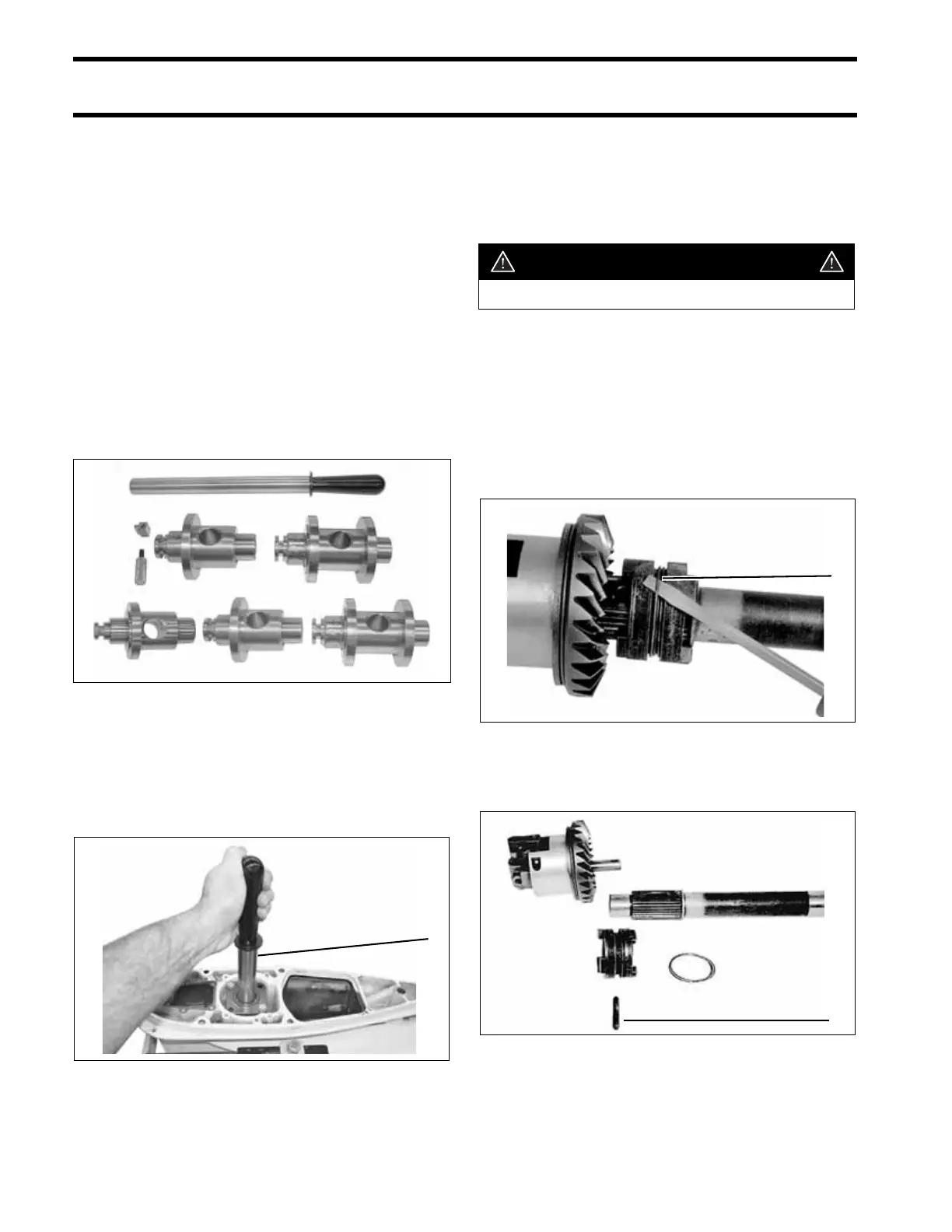

Use Gearcase Alignment Gauge Kit, P/N 5006349

to check the condition of gearcase housing prior

to reassembly. Refer to instructions provided with

kit. Use additional Gauging Head as follows:

• P/N 352879, for “S2” Type gearcase housings

• P/N 5007750, for “L2” Type gearcase housings

• P/N 5007749, for “M2” Type gearcase housings

IMPORTANT: DO NOT force gauging shaft into

alignment hole. Shaft MUST slide easily into hole

of gauging head. If shaft does not slide into hole,

gearcase housing is damaged and must be

replaced.

SHIFTER, BEARING AND

SEAL SERVICE

Shift Housing Disassembly

IMPORTANT: The shift housing and bearing are

serviced as an assembly. If either are worn or

damaged, replace the complete assembly.

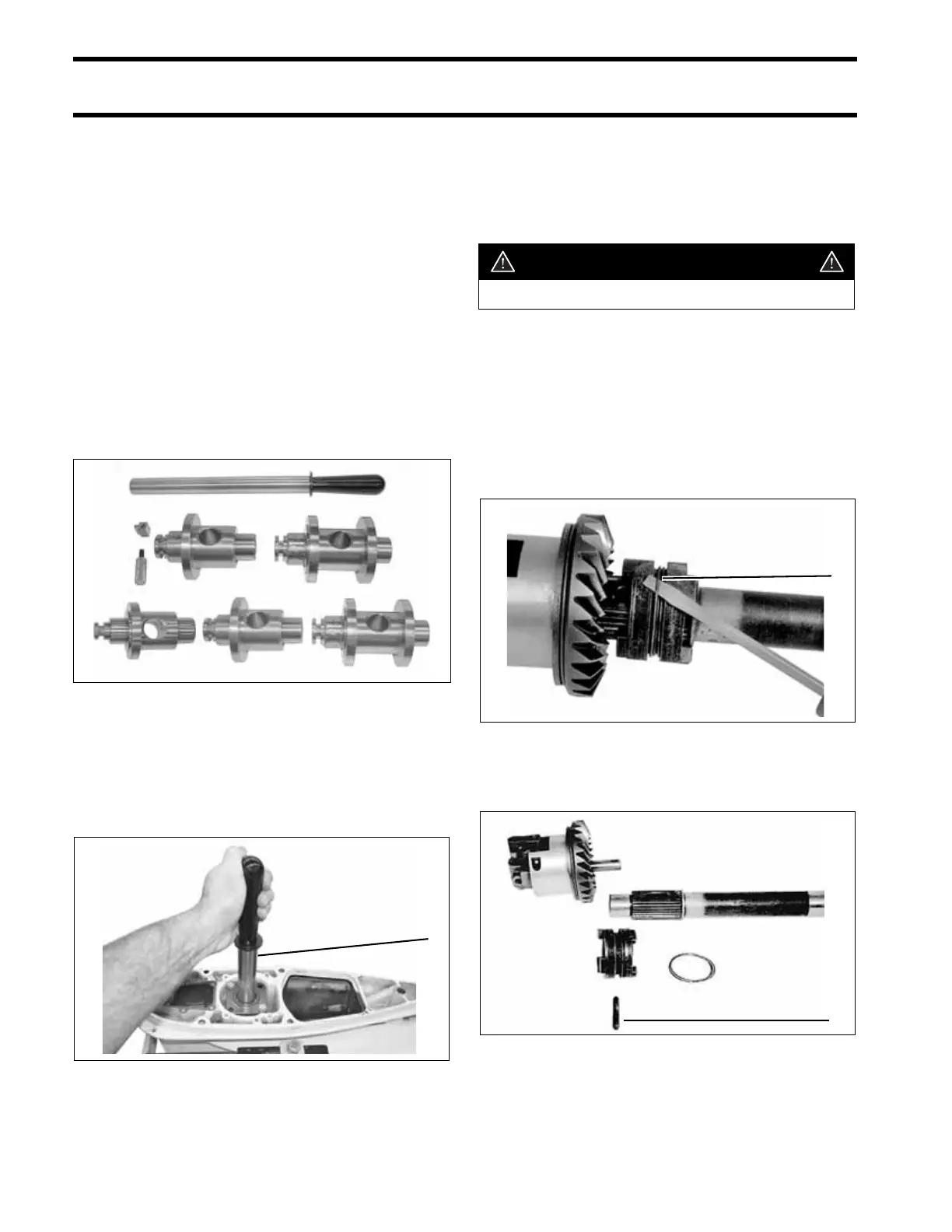

Insert a suitable tool under one end of the clutch

dog spring and remove it from its groove by

unwrapping it from around the clutch dog. Dis-

card the spring.

Push the pin out of the clutch dog. Remove all

parts.

006787

1. Gauging shaft 004347

1

WARNING

Wear safety glasses to avoid injury.

1. Clutch dog spring COA3560

1. Pin COA3561

1

1

Loading...

Loading...