355

GEARCASE – COUNTER ROTATION

GEARCASE ASSEMBLY

13

IMPORTANT: Pinion, clutch dog and forward

gears must align properly for bearing housing to

seat properly.

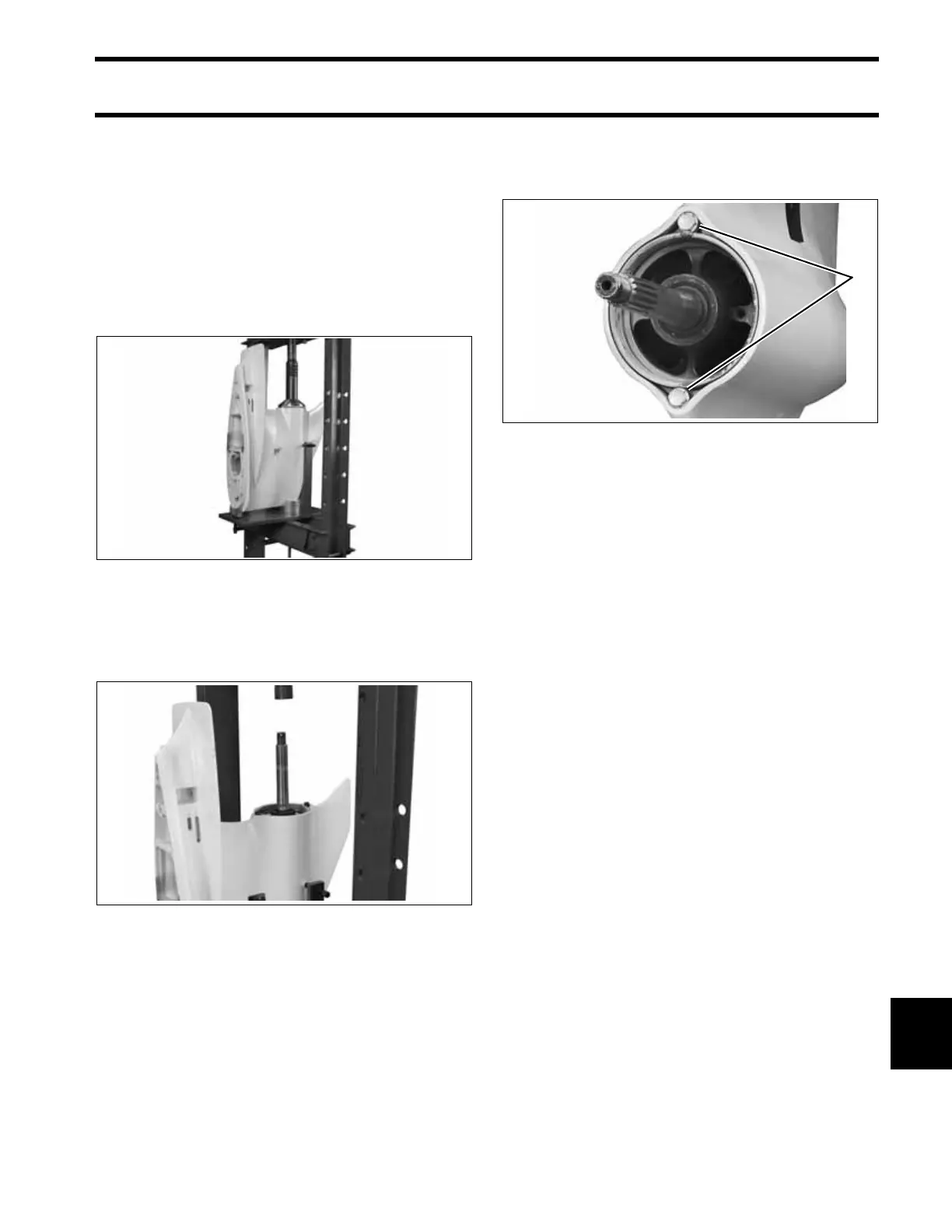

Use Installer Handle, P/N 345822, Propeller Shaft

Bearing Housing Installer, P/N 354057, Gearcase

Fixture, P/N 354059 and an appropriate floor

press (10 ton or greater) to install housing into

gearcase. Align and level gearcase assembly in

fixture as shown. Secure fixture to floor press.

Housing must be completely seated in gearcase

to install retainer screws. Bearing housing is

approximately level with gearcase.

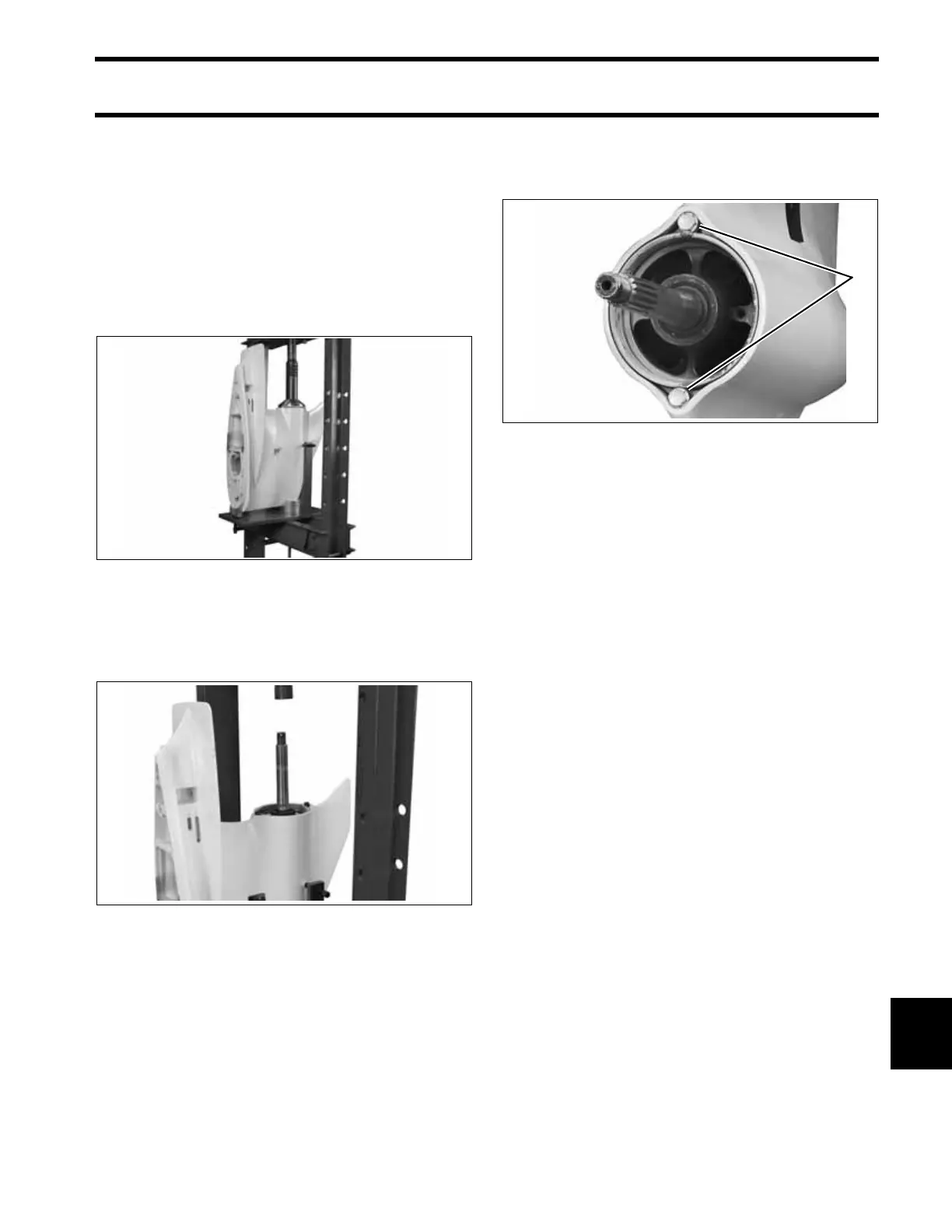

Apply Ultra Lock to threads and install two retain-

ing screws. Tighten screws to a torque of 18 to 20

ft. lbs. (24 to 27 N·m).

Final Assembly and Adjustment

To complete gearcase assembly, refer to:

• GEARCASE LEAK TEST on p. 300

• WATER PUMP SERVICE on p. 304

• SHIFT ROD ADJUSTMENT on p. 306

• GEARCASE REMOVAL AND INSTALLATION

on p. 301

• Gearcase Lubricant on p. 79

• Propeller Hardware Installation on p. 67

• Trim Tab Adjustment on p. 70

During break-in period of a reassembled gear-

case, change the gearcase lubricant between 10

to 20 hours of operation.

“M2” Type Gearcase

1. Retainer Tab Notch

006848

006849

1. Retainer screws 006835

1

Loading...

Loading...