280

MIDSECTION

EXHAUST HOUSING

V4 MODELS

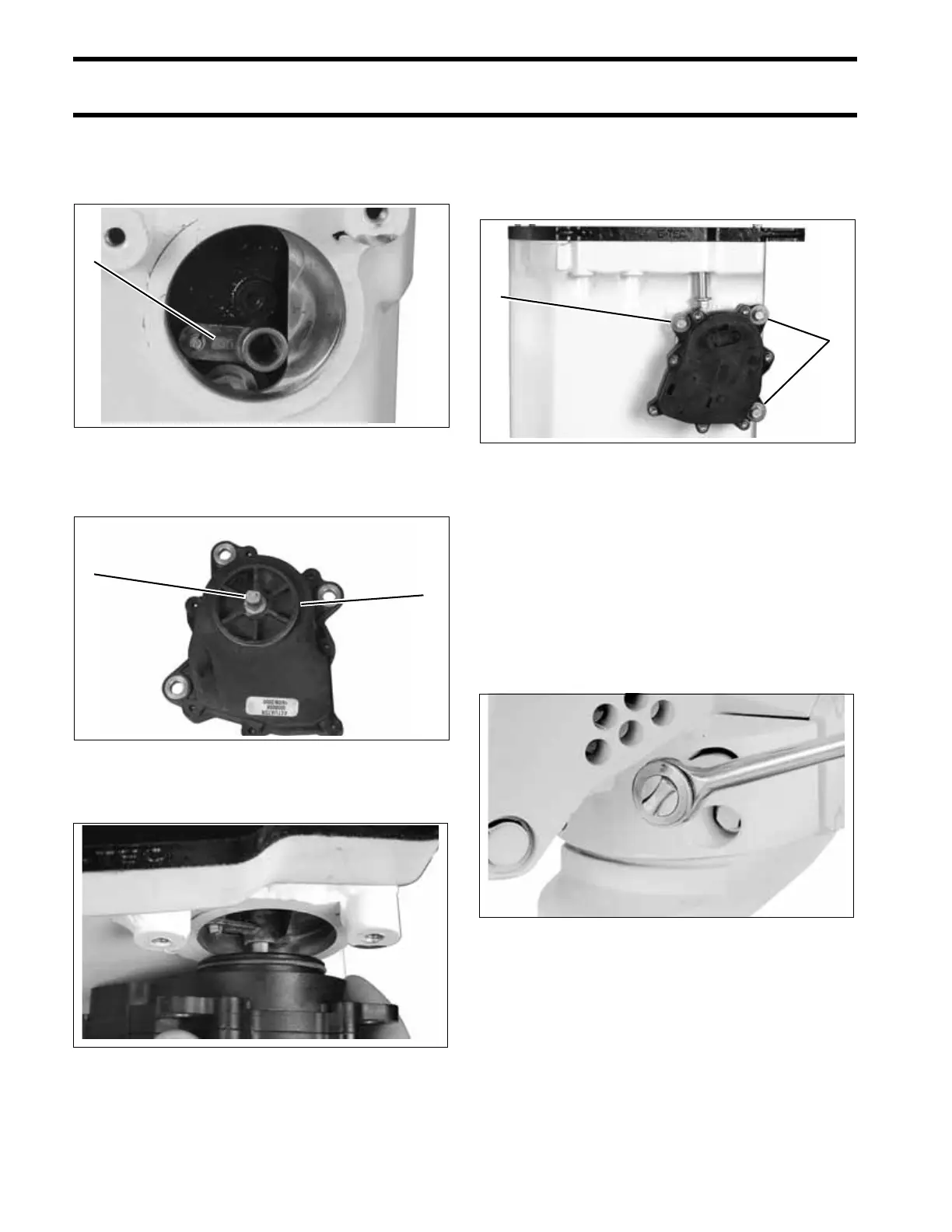

Check that exhaust valve linkage is oriented as

shown. “OUT” marking on lever must be visible.

Apply a small amount of Triple-Guard grease to

the actuator shaft and o-ring.

Carefully engage actuator shaft in linkage lever.

Rotate and push actuator into position. Apply Tri-

ple-Guard grease to screw threads and install

screws and washers. Tighten screws to 60 to 84

in. lbs. (7 to 9.5 N·m).

IMPORTANT: Fill actuator electrical connec-

tors with Electrical Grease before installation.

Exhaust Housing Installation

Bring the exhaust housing into position with the

stern bracket.

Install four new lower mount screws with lock-

patch. Tighten screws to a torque of 38 to 45 ft.

lbs. (51 to 61 N·m).

Install powerhead. Refer to POWERHEAD

INSTALLATION on p. 251.

Install gearcase. Refer to Gearcase GEARCASE

REMOVAL AND INSTALLATION on p. 301.

1. “OUT” mark 005208

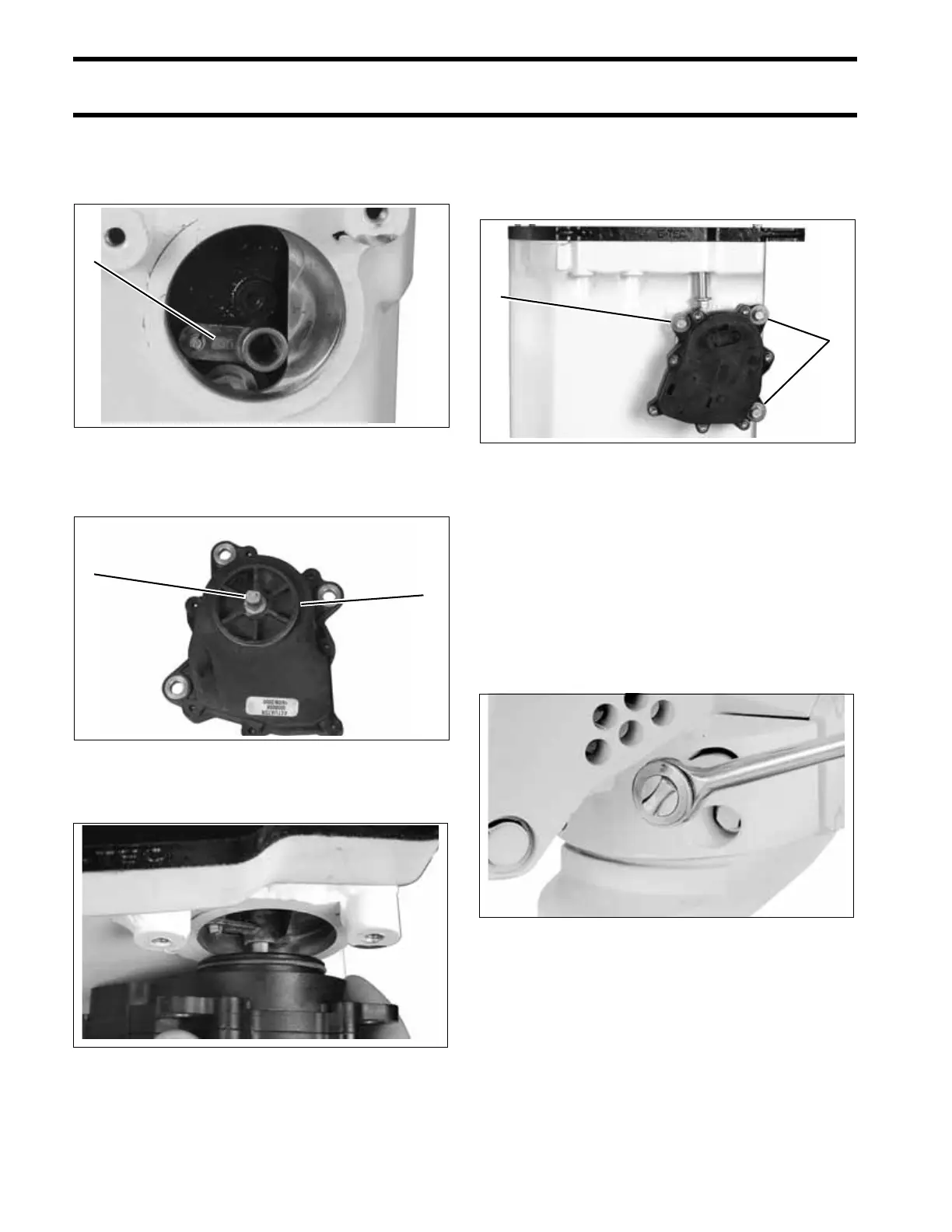

1. Shaft

2. O-ring

005209

005219

1

2

1

1. Actuator screws 005206

23036

1

1

Loading...

Loading...