152

ELECTRICAL AND IGNITION

FLYWHEEL AND STATOR SERVICING

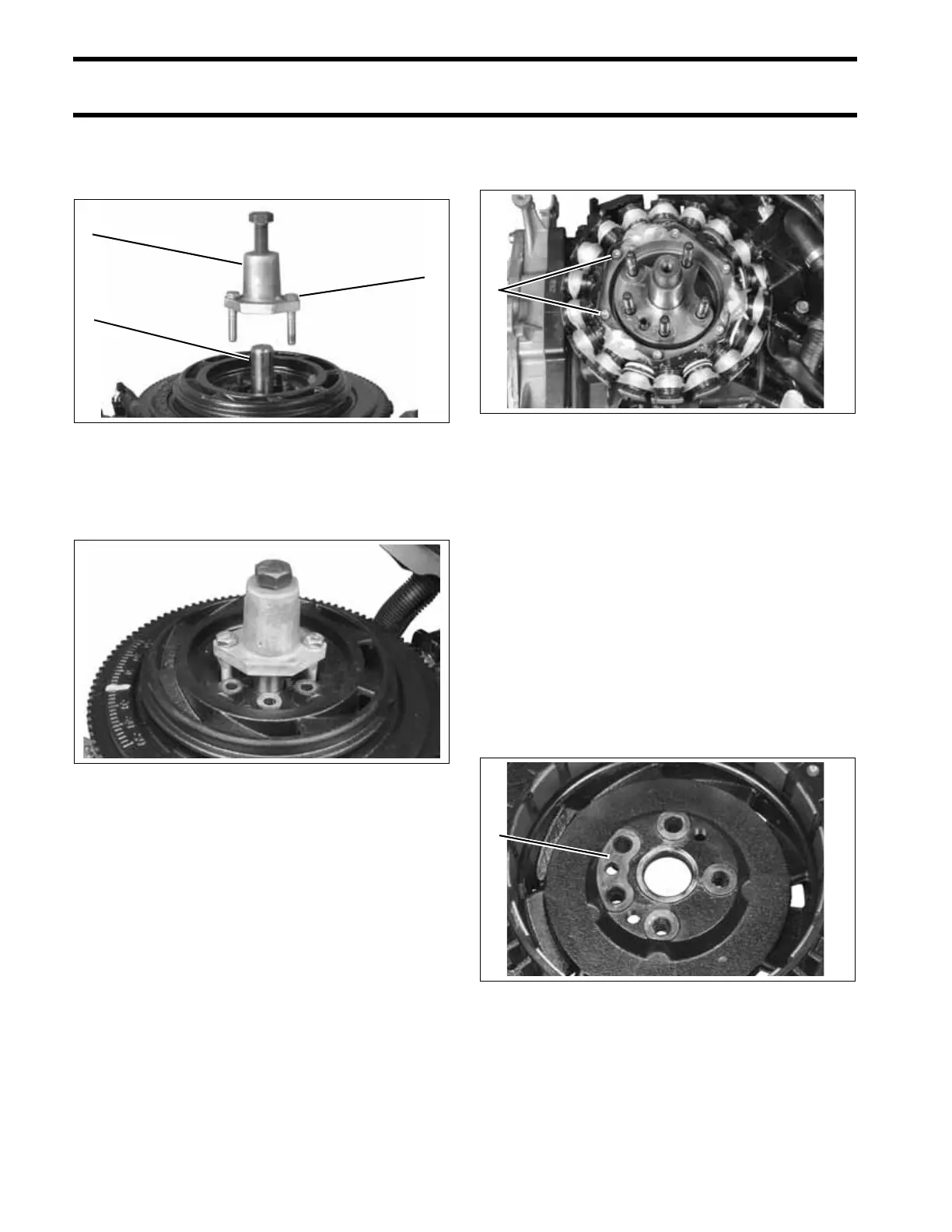

Use two 3/8-24x2 in. screws from the adaptor kit

to attach the tool to the flywheel. Two holes are

tapped in the flywheel for the tool.

Turn the center screw of the puller in to lift the fly-

wheel off of the crankshaft.

Stator Service

Remove six allen head screws to remove stator.

To install stator, position stator on cylinder block.

Apply Nut Lock to screw threads. Install screws

and tighten in crossing pattern to a torque of 24 to

36 in. lbs. (3 to 4 N·m).

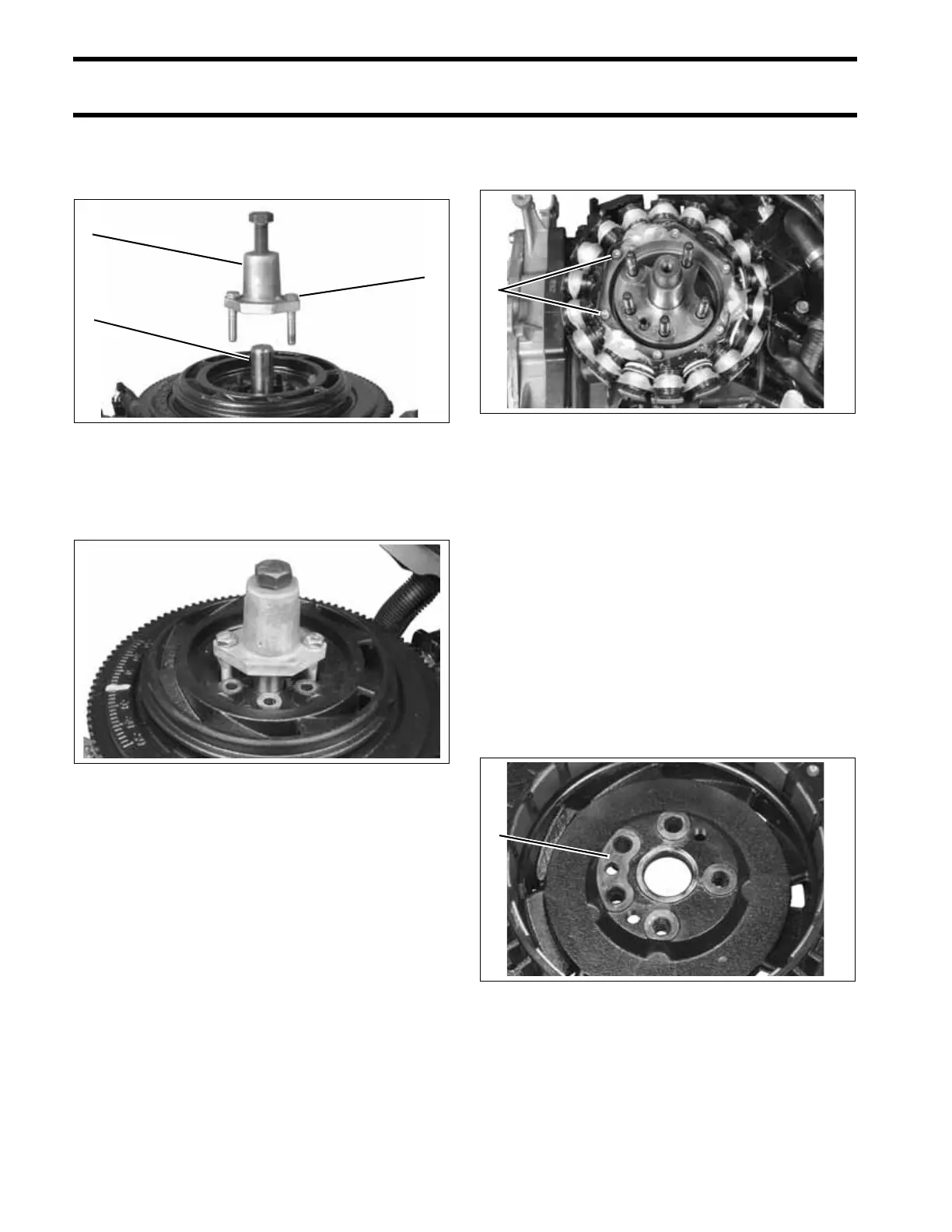

Flywheel Installation

If studs must be replaced in crankshaft, apply

Ultra Lock to threads and tighten by hand, no

more than 48 in. lbs. (5.5 N·m).

Remove any debris from the flywheel magnets

and the flywheel and crankshaft mating surfaces.

Apply Nut Lock to the raised mounting bosses on

the bottom of the flywheel.

1. Puller

2. Bushing

3. Screws - 3/8 - 24 x 2 in. (2)

005369

005381

3

1

2

1. Stator screws 005382

1. Flywheel mounting bosses 005370

1

1

Loading...

Loading...