370

TRIM AND TILT

TROUBLESHOOTING

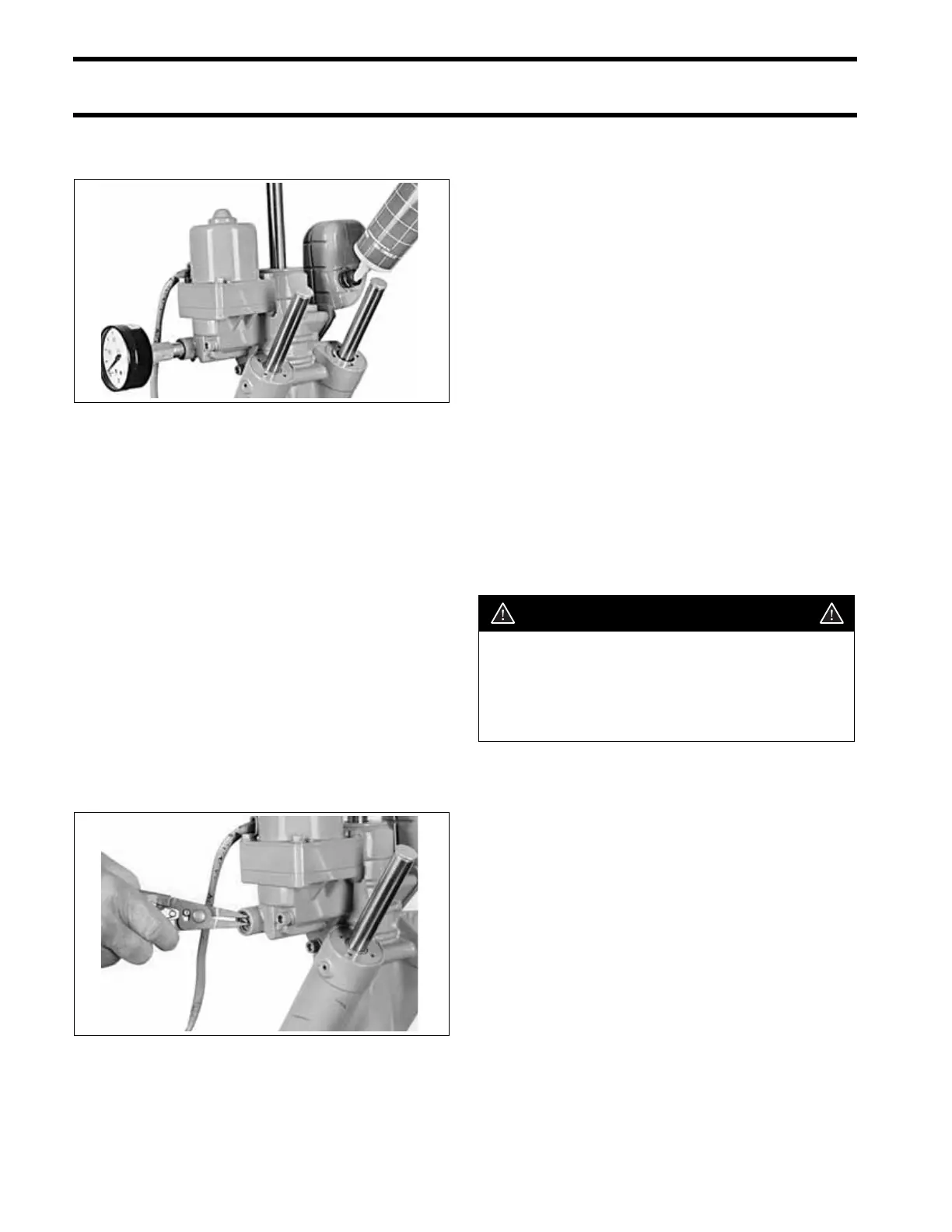

all rods must be completely extended to check

fluid level.

Starting with the tilt cylinder fully retracted, run the

unit UP.

• The gauge should show 0 to 200 psi (0 to 1379

kPa) as the tilt cylinder is extending.

• The gauge should show 1400 to 1600 psi (9653

to 11032 kPa) as the unit stalls.

• Release the switch and watch for a pressure

drop. The stall pressure reading must not drop

more than 200 psi (1379 kPa) after motor stops.

If results vary from the above limits, there is a

problem in the UP circuit. Refer to MODES OF

OPERATION (Three Piston System) on p. 361

for circuit description.

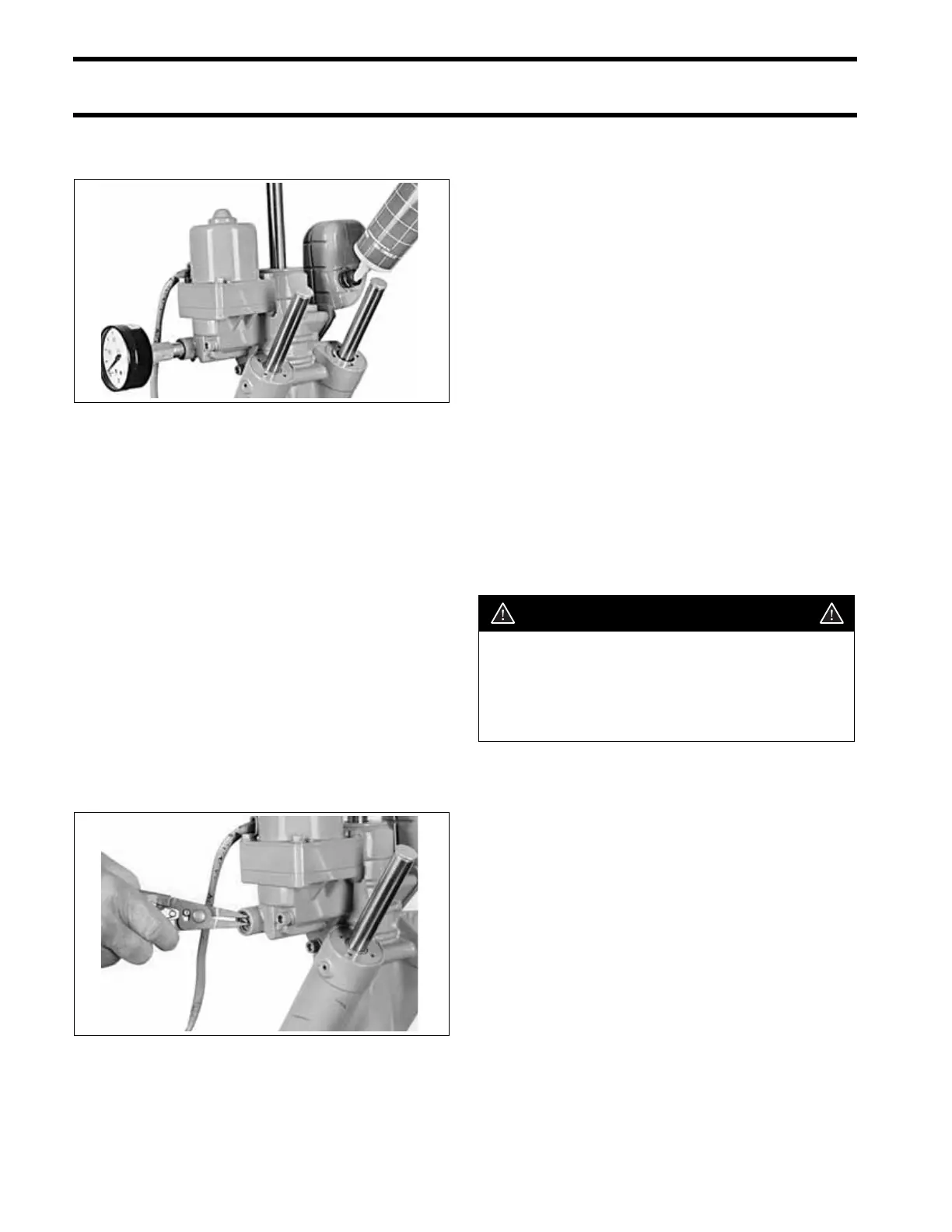

STEP 2

Remove the manual release valve retaining ring

using retaining ring pliers.

Remove the manual release valve. Install pres-

sure gauge and adapter “B” to check problems in

the DOWN circuit. Cycle the unit down and up

several times to purge air. With all rods fully

extended, run the unit down momentarily to

reduce pressure. Check fluid level again, and add

fluid if necessary. Remember that all rods must be

completely extended to check fluid level.

Starting with the tilt cylinder fully extended, run the

unit DOWN.

• The gauge should show 0 to 200 psi (0 to 1379

kPa) as the tilt cylinder is retracting.

• The gauge should show approximately 800 psi

(5516 kPa) as the unit stalls.

• Release the switch and watch for a pressure

drop. The stall pressure reading must not drop

more than 200 psi (1379 kPa) after motor stops.

If results vary from the above limits, there is a

problem in the DOWN circuit. Refer to MODES

OF OPERATION (Three Piston System) on

p. 361 for circuit description.

Check fluid level again and add fluid, if necessary.

41757

41754

CAUTION

After tests are complete, run the unit up,

then down momentarily. Cycle the unit

down and up several times to purge air.

With all rods fully extended, run the unit

down momentarily to reduce pressure.

Loading...

Loading...