Installation Instructions

18.12.15 Kapitel/Chapter 6: Installation Instructions - Seite/Page 111

separate.

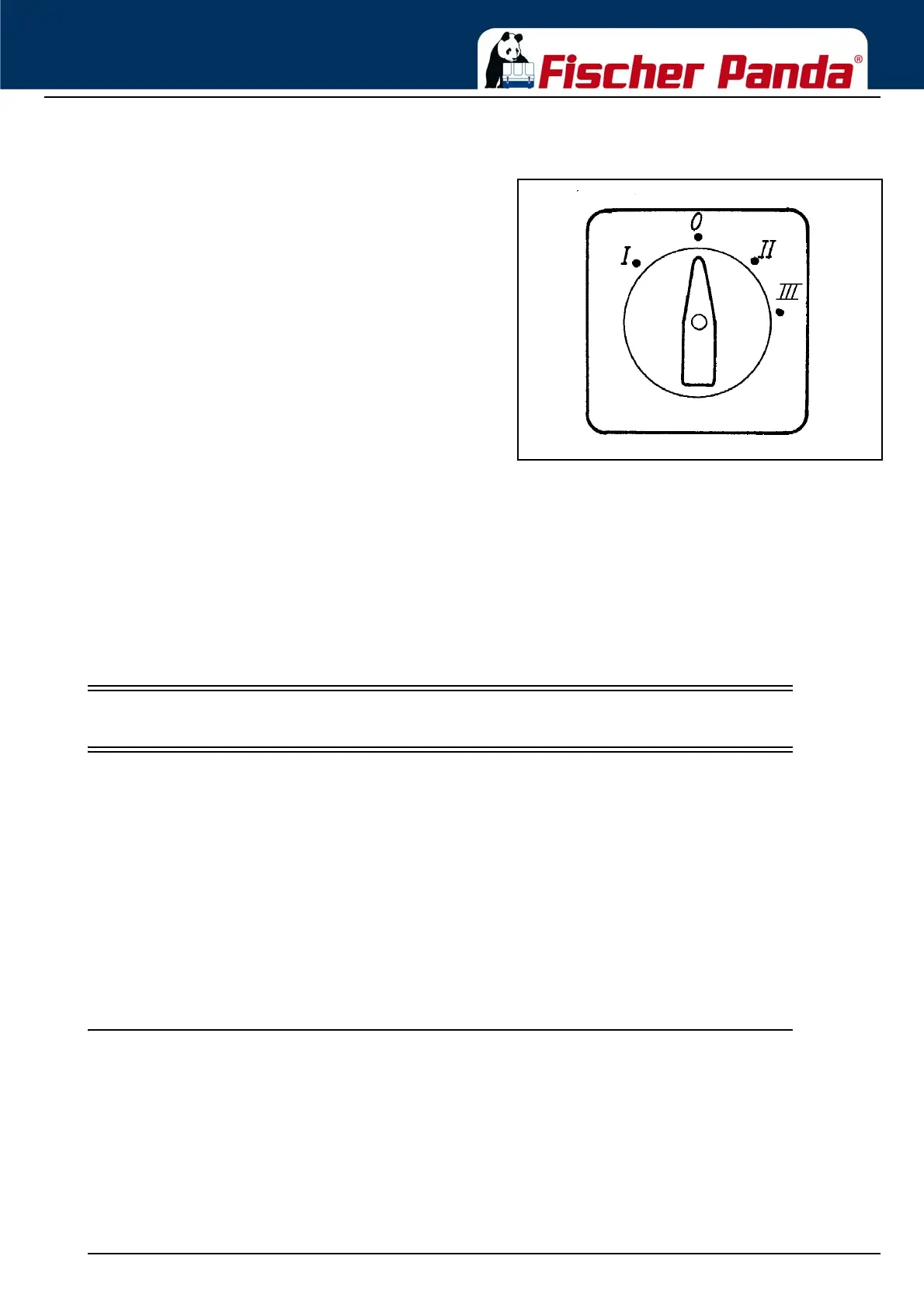

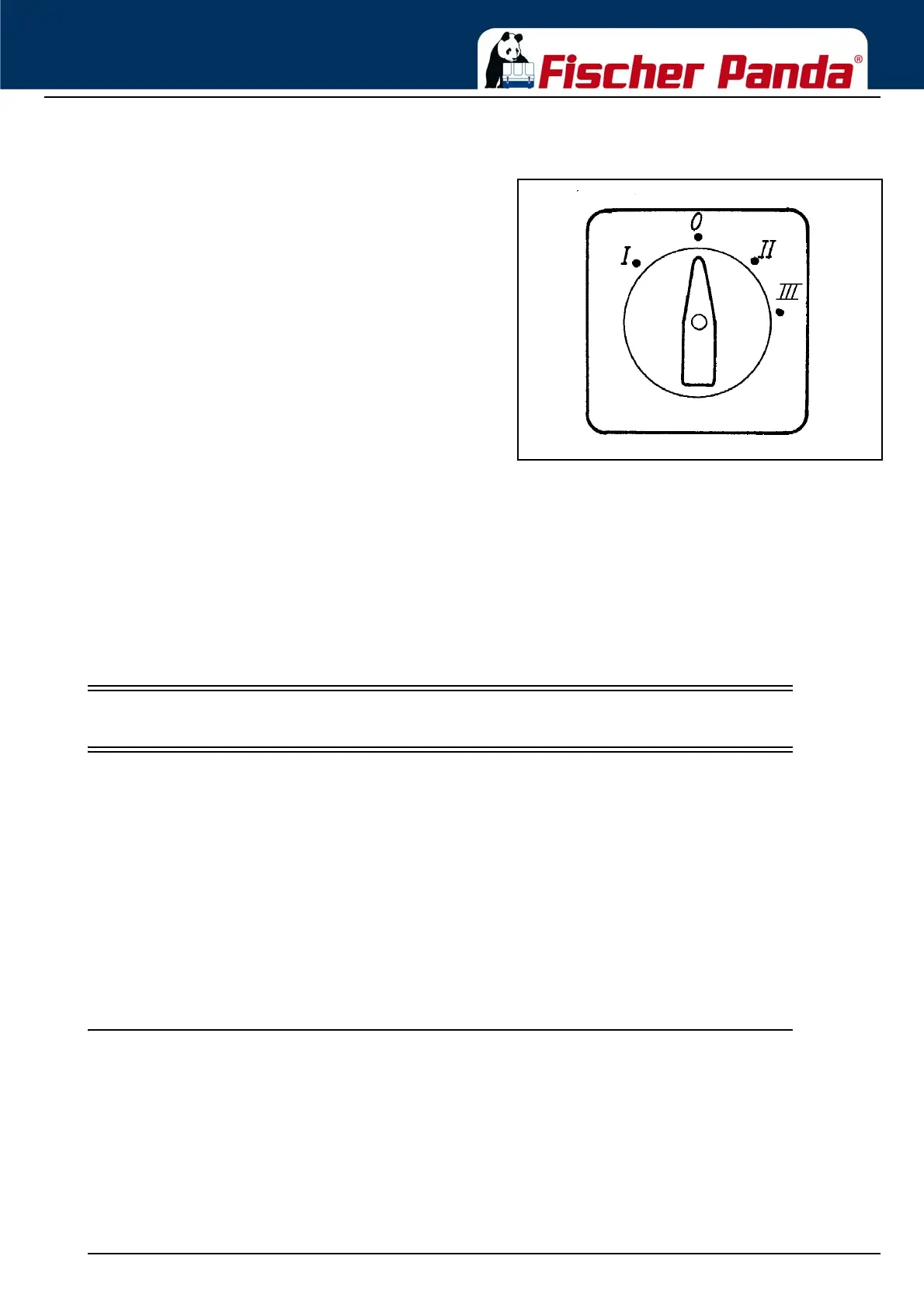

Fig. 6.16.4-1: 3-way cam switchAs disconnector a cam switch should be used. This

switch should have three positions: "Shore power" -

"OFF" - "Generator". If an (DC-AC) inverter is used, a

fourth position will be required.

0 Off

I Generator

II Shore power connection

III Inverter

Example

The cam-type switch must have 2 poles, so that "MP" and "phase" can be switched off.

If a 3-phase current system is also installed with the option of supplying from either the generator or shore power, an

additional switch must be installed to keep these systems separate.

An alternative to a manual rotating switch is an automatic power relay. When the generator is not running, the relay

remains in the shore power position. As soon as the generator is running, the power relay switches automatically to

the generator position.

It is necessary that the 3-phase AC and the single-AC have to be installed separately from each other.

6.17 Special recommendations

6.18 Instructions on prevention of galvanic corrosion

Galvanic corrosion

If several machines are connected by a common electrical potential (e.g. mass) and the system is also still in contact

with other metal parts (e.g. the hull of a neighbour ship), always assume that the different components proceed

different electrical voltage, which affect the entire system and the components. DC voltage causes an electric

current, if in the environment of these parts electrically leading liquids (electrolyte) are available. This is called

„galvanic process“. The electrical charge of the negatively charged fields (anode) is led to the positively charged field

(cathode). The negatively charged part (anode) „is sacrificed“ thereby, i. e. that the electrical particles at the surface

of the material caus decomposition with this chemical process. Since aluminium is an electrically negatively charged

metal, aluminium will play the role of the anode compared with most remaining metals. This applies in particular to

copper, brass, and also steel and stainless steel etc. These metals are positively charged.

6.18.1 Instructions and measures on prevention of galvanic corrosion

Several measures must be considered when making the installation so that galvanic corrosion can be avoided as

much as possible:

• Separation of the water column (between raw water and generator) after shutdown. This can either be a stop vlave

turned by hand (Attention! The valve must be closed after each operation) or by the installation of an automatic

ventilation valve. In this case the valve opens and closes automatically.

• Connecting all components (hull outlet, generator, heat exchanger etc.) to a common potential. For this all elements

of the installation are connected by a cable (earthed).

• Strict separation of the generator from the 12 V on-board power supply, that means potential free installation of the

Loading...

Loading...