Maintenance Instructions

18.12.15 Kapitel/Chapter 7: Maintenance Instructions - Seite/Page 169

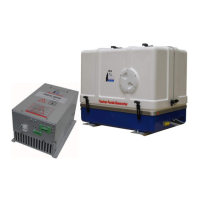

Fig. 7.20-3: Injection nozzles3. Loosen the union nut on the injection lines (1). Wrench

with W.A.F. of 17 mm.

For assembly:

• Blast dust out of the lines using compressed air. Then,

reassemble the lines by proceeding in the reverse order of

steps.

(1) Injection line

Fig. 7.20-4: Injection nozzlesNozzle holder assembly and glow plug

1. Dismount the return line (1). Wrench with W.A.F. of

17 mm.

2. Remove the nozzle holder assembly (4). Wrench with

W.A.F. of 21 mm.

3. Remove the copper seal (5) and the heat shield (6).

4. Dismount the connector (2) from the glow plugs (3)

5. Remove the glow plugs (3).

For assembly:

• Replace the copper seal and the heat shield with new parts.

(1) Return line

(2) Connector

(3) Glow plug

(4) Nozzle holder assembly

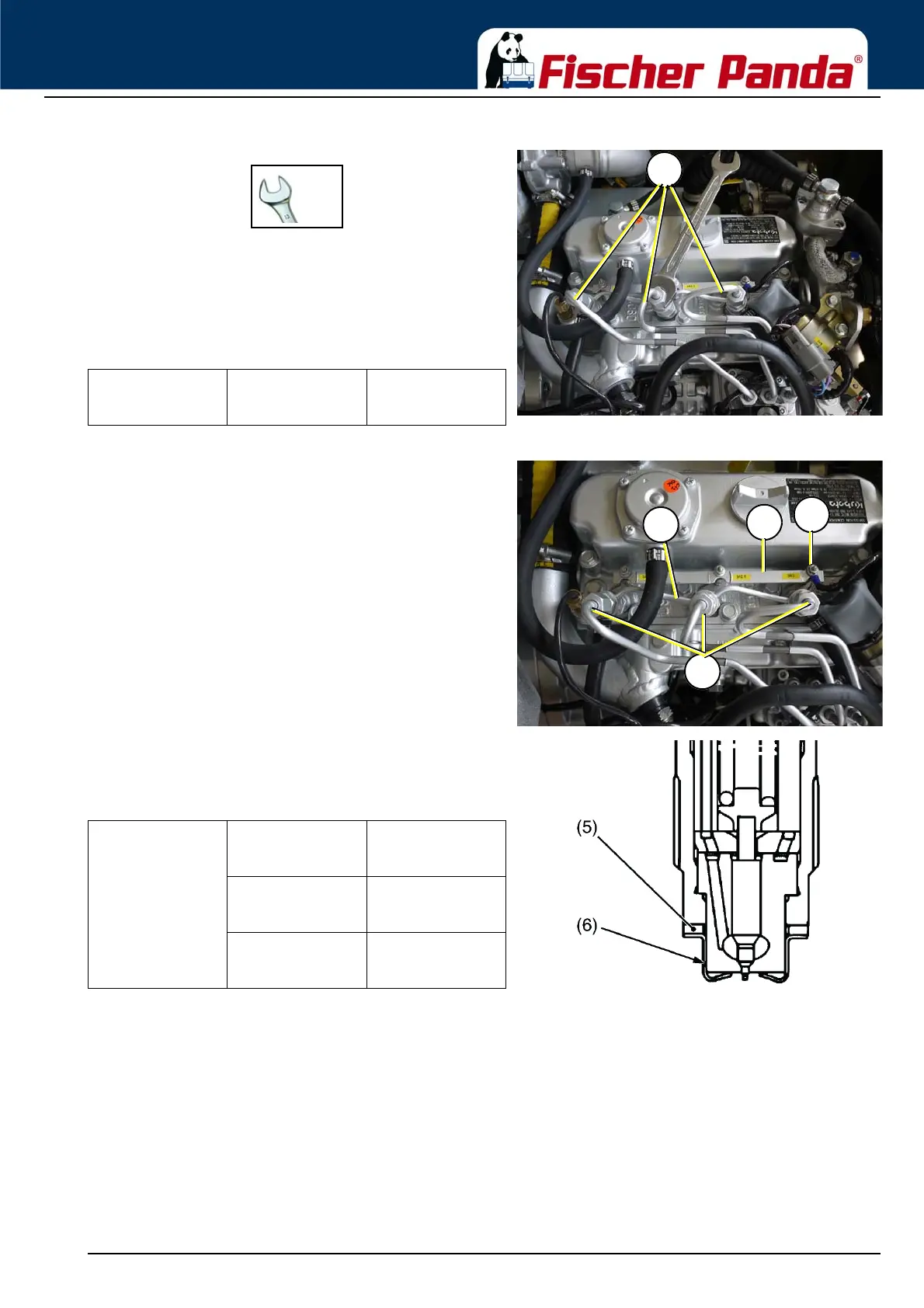

(5) Copper seal

(6) Heat shield

Torque Injection line union nut 24.5 to 34.3 Nm

2.5 to 3.5 kgm

18.1 to 25.3 pound-foot

Torque Fixing nut for overflow

oil line

19.6 to 24.5 Nm.

2.0 to 2.5 kgm

14.5 to 18.1 pound-foot

Nozzle holder assembly 49.0 to 68.6 Nm

5.0 to 7.0 kgm

36.2 to 50.6 pound-foot

Glow plug 7.8 to 14.7 Nm.

0.8 to 1.5 kgm

5.8 to 10.8 pound-foot

Loading...

Loading...