Rack and pinion hoist

Assembly and Operating Instructions

72 / 100 BL108 GB Edition 03.2018 Rev. 02

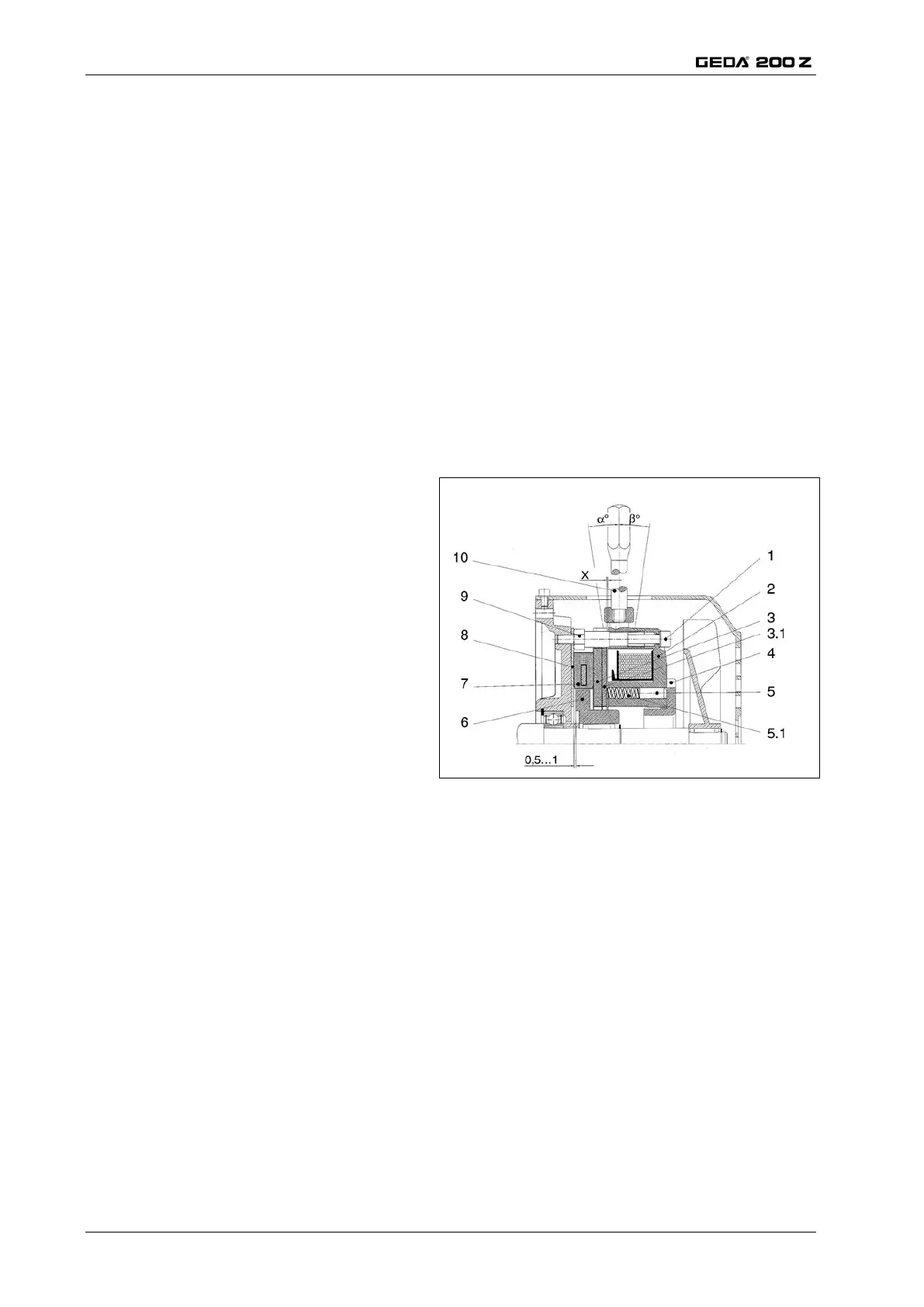

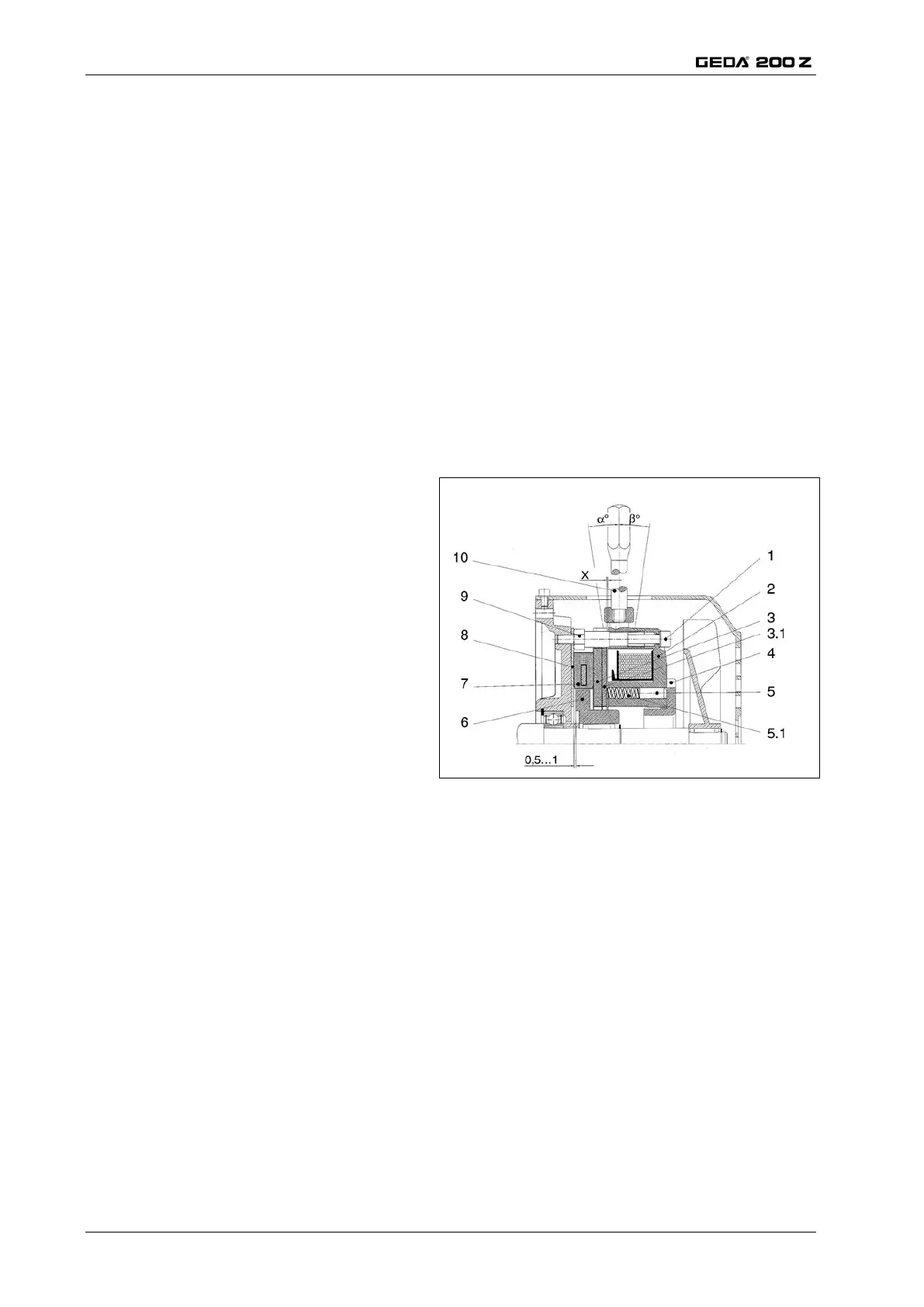

8.4.4 Motor brake

Check the braking distance

Carry out a test run with the hoist loaded and check whether the

motor brake overtravel in downwards travel is exceeded (trolley or

platform must not come to rest on the buffers).

Adjust the motor brake

The working air gap is measured in the braking position between the

anchor plate and the magnetic body. It increases due to wear. If the

wear of the brake pad is advanced to the point where the maximum

possible air gap of 0.5 mm is reached, the brake must be readjusted

because safe brake release can no longer be guaranteed. This is

evident by dwindling brake power or longer braking distance. The

minimum thickness of the pad is 6.5 mm, and the working air gap

should be set at 0.25 – 0.3 mm.

2 = Magnet

3 = Anchor

4 = Adjusting ring

5 = Pressure bolt

5.1 = Compression spring

6 = Hub

7 = Lining

8 = Friction pad

9 = Adjustment spacer

(banjo bolt)

10 = Manual release

Air gap (X) min. (adjusted) 0.25 mm

Air gap (X) max. (wear) 0.5 mm

Lining thickness min. 6.5 mm

Loading...

Loading...