Maintenance

50940411/G0219 144 Printed in U.S.A.

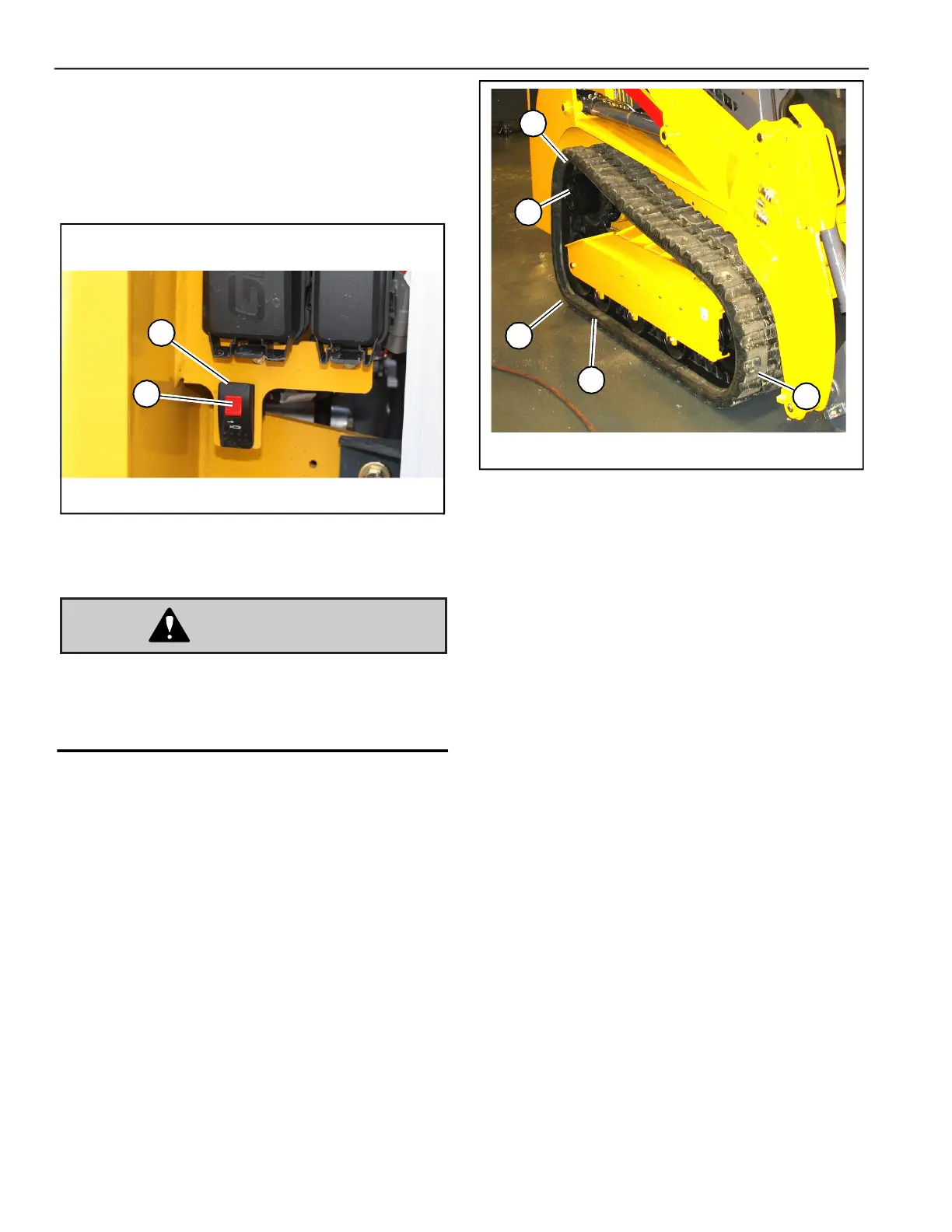

2. With the machine running and the drive system

not moving, open the engine compartment. Press

and hold the lock button (L, Fig. 151) on the

track tension service switch, and press the top

(M) of the switch to set the track tension

cylinders into the service (retracted) position.

3. When the track tension cylinders are in the

service (retracted) position, shut off the machine.

Use solid support blocking. Never rely on jacks

or other inadequate supports when

maintenance work is being done. Never work

under any equipment supported only by jacks.

4. Raise the machine about 150 mm (6”), so the

tracks are free to move.

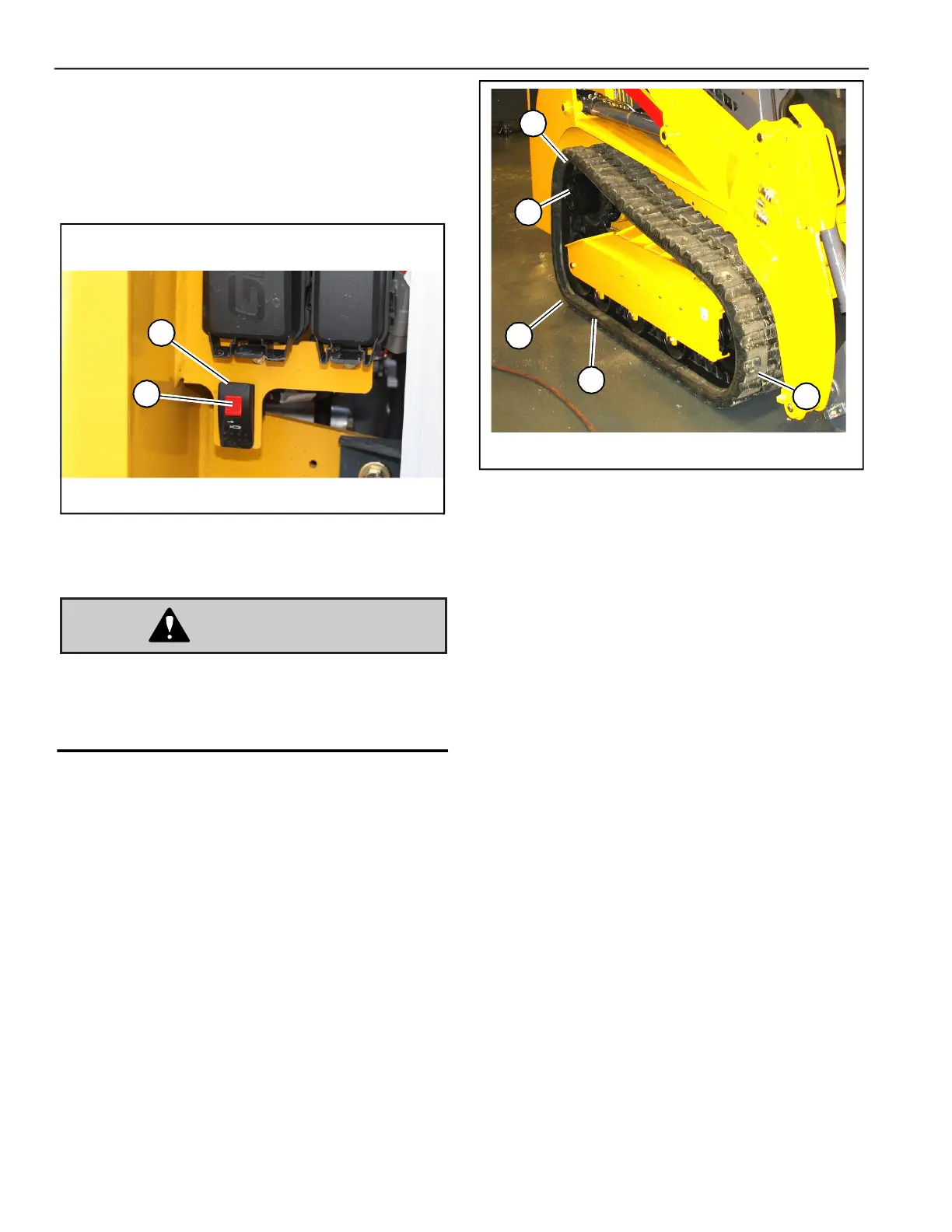

5. Use a pry bar to pry/guide the old track at (R,

Fig. 152) off the front idler wheel.

6. Using a hoist with a hook installed and a pry bar,

lift/guide the old track at (T, Fig. 152) off the

drive sprocket. Remove the old track.

7. Using a hoist with a hook, lift the new track at

(T), and manoeuver the track under the rear idler

wheel at (Q) using a pry bar and your foot.

IMPORTANT:

Guides on the inside of the track

must straddle the rear idler.

8. Place a block under the new track at (S), to hold

the track against the bottom of the rear idler

wheel.

9. Using a hoist with a hook and a pry bar, lift/

guide the new track at (T) onto the drive

sprocket.

IMPORTANT:

Lugs on the inside of the track must

be fully engaged by drive sprocket (P).

L

M

Fig. 151 – Track Tension Switch

Models RT175/RT210 Shown; Other

Machines Similar

Fig. 152 – Track Removal/Installation

R

S

Q

P

T

Loading...

Loading...