28 Sabre Owner’s Guide

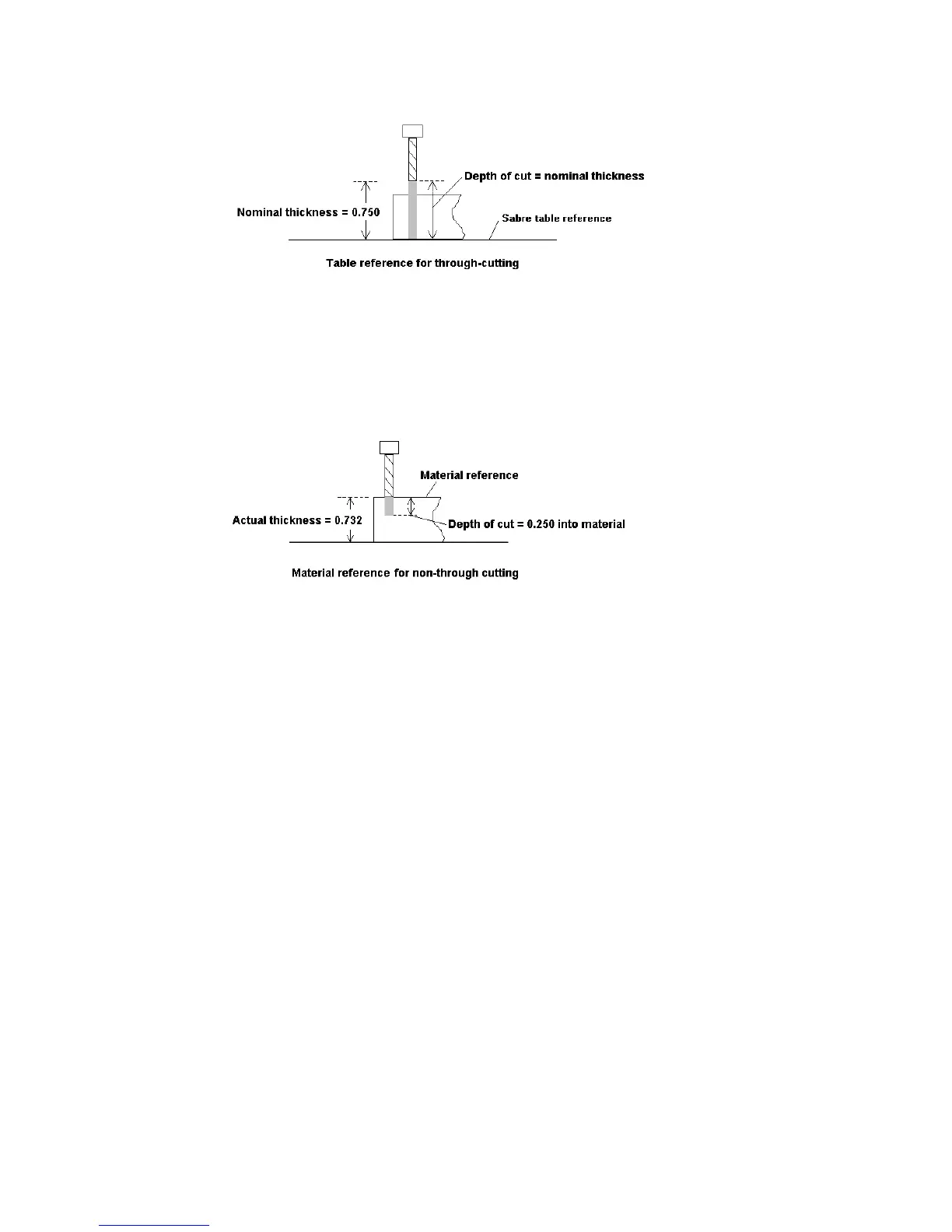

Non-through cut tool paths rout into the material to a specified depth without cutting

completely through the material. The Sabre must know the location of the top surface of the

work piece to achieve a precise depth of cut. We call this a material surface reference. A

material surface reference is used with the actual material thickness. Establish an actual

material thickness by initializing the tool to the material surface with the Z-Init gage. Any errors

in referencing the material surface result in tool paths that are too shallow or too deep.

Associating the type of surface reference to specific tool paths in ART Path automates the

cutting of a job with multiple tool paths. The Sabre retains the nominal and actual material

thickness in its memory. When processing the job, Sabre uses the specified surface reference and

the material thickness for each tool path without operator direction.

Setting the surface reference

In ART Path, you must designate a surface reference for each tool path routed by the Sabre.

Depending on the application, generated tool paths may use either a table or material surface

reference. The surface reference point, along with the material thickness is used when

initializing the Z axis with each tool.

When creating three-dimensional signage, ART Path generates tool paths that produce two

types of results:

♦

through-cut

♦

non-through cut

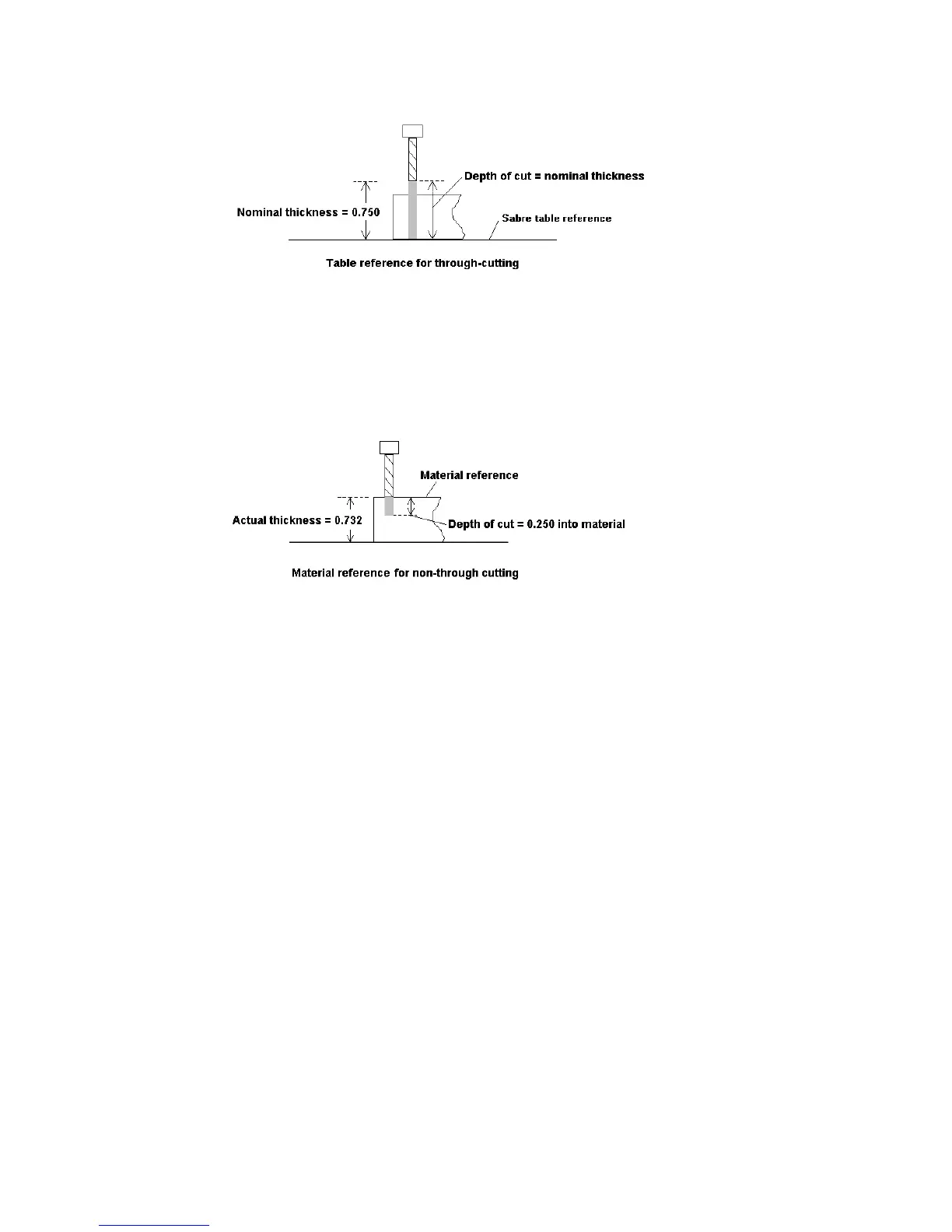

When cutting through the material, choose Table as the type of surface reference for the job.

ART Path uses the Z initialization value that results from a table initialization as the surface

reference.

When generating tool paths that do not result in through-cutting, choose Material as a surface

reference. ART Path uses the Z initialization value that results from a material initialization as

the Surface Reference.

Loading...

Loading...