Options 69

Note: The Mist Coolant Option cannot be used at the same time as the Chip Removal System

or the Engraving Option.

Note: The Mist Coolant System requires a compressed air supply of 80 to

100 psi.

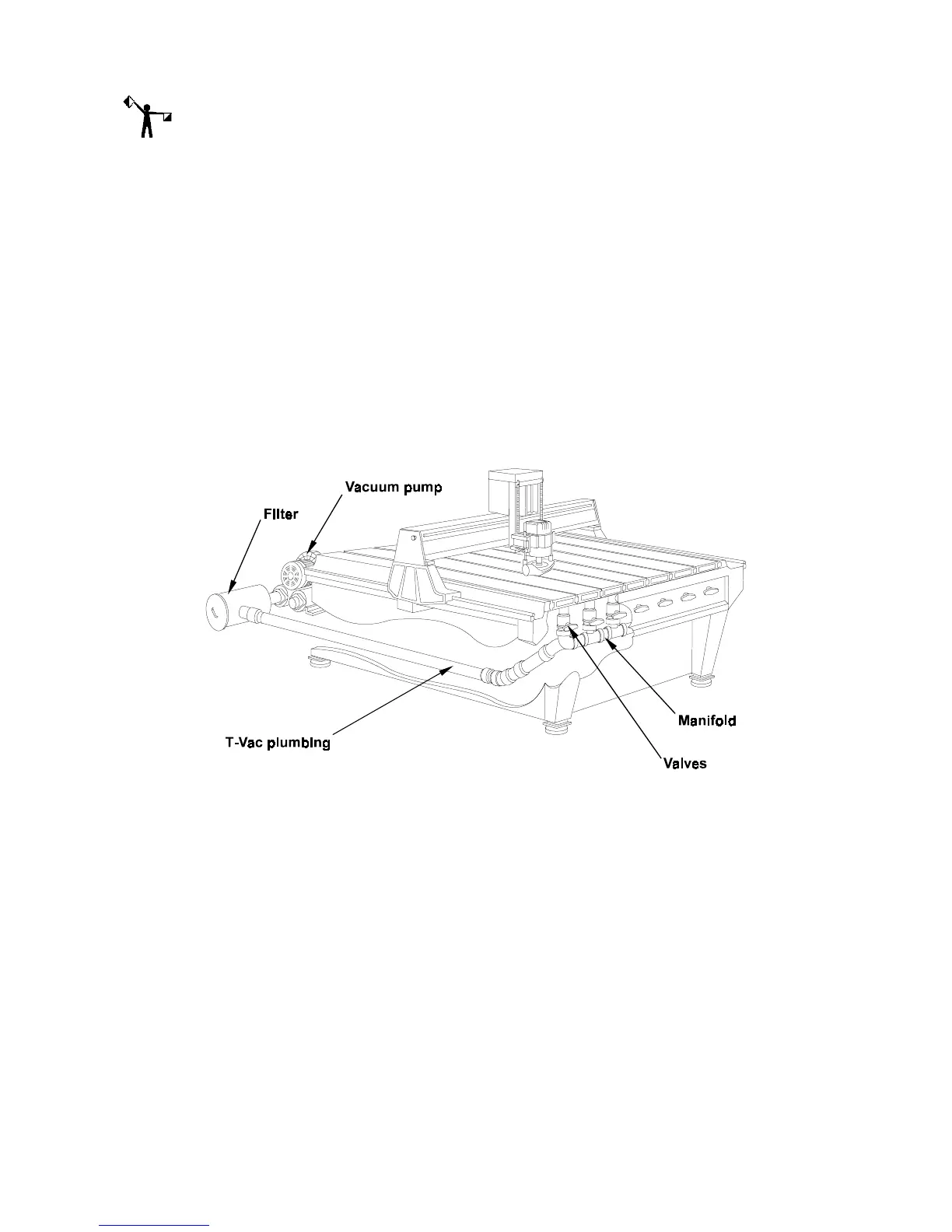

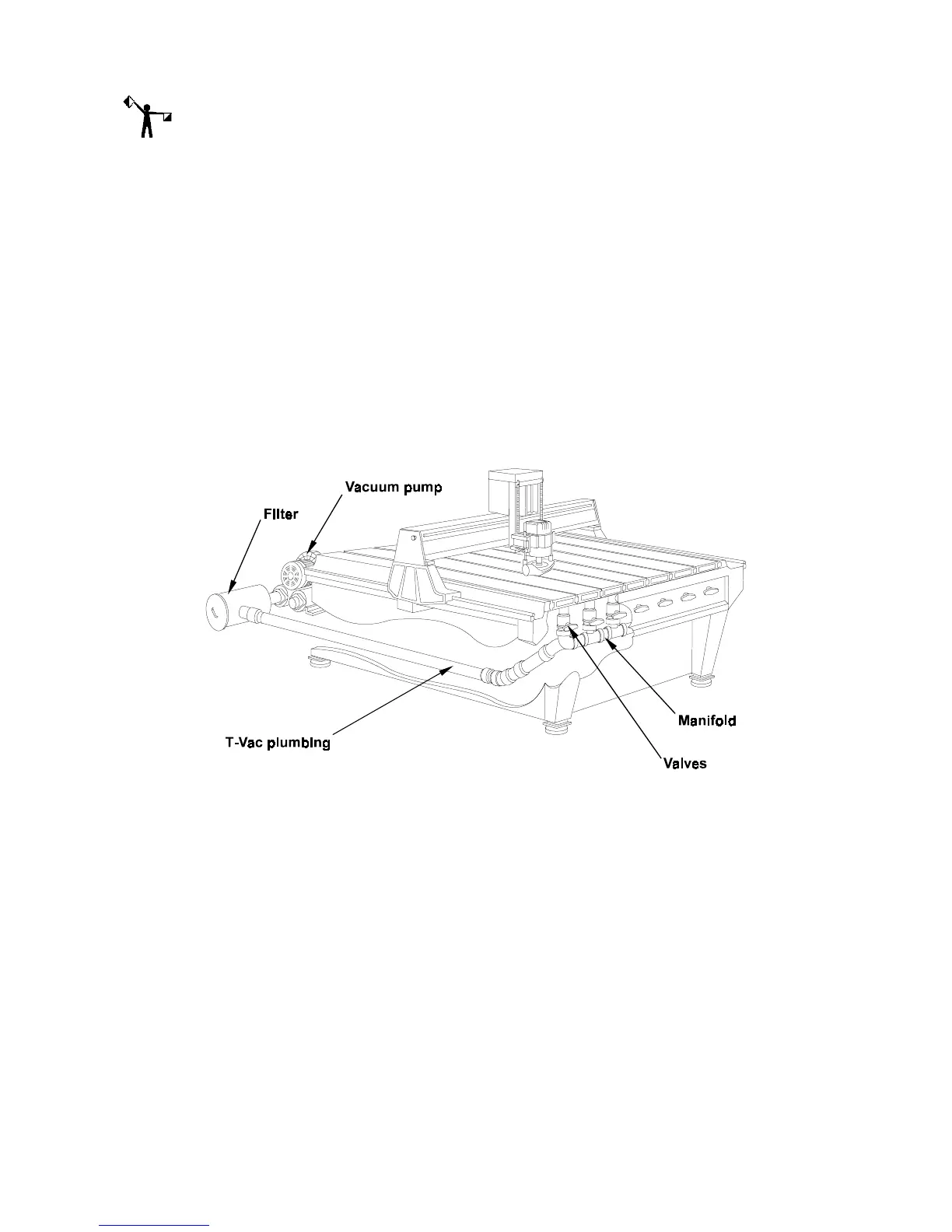

T-Vac Option

The T-Vac Option uses vacuum to hold a workpiece easily and securely on the Sabre routing

surface. It provides seven individually controlled vacuum zones on the router table to hold

down a wide range of workpiece sizes. Depending on the material and the job, the T-Vac may

eliminate the need for clamps, adhesive, and sacrificial material, thus maximizing table area and

minimizing setup time.

If your system was ordered with the T-Vac Option, the valves and manifold are installed at the

factory and all pipes and fittings required to connect to the vacuum pump are supplied with the

Sabre. A separately purchased vacuum pump and filter are required. Pump and filter

specifications are available from your Gerber distributor.

Engraver and Engraver Vacuum Options

The Engraver Option provides increased engraving accuracy from its floating Z axis. It also

allows for quick tool changes by letting you initialize several tools before locking the Z axis.

A specially designed Engraver Vacuum Option can be separately purchased to clean debris

from the engraving area during operation. The Engraver Vacuum Option is a quiet,

conveniently-sized system designed for use with the Engraving Option to clean debris from the

table and engraving area.

Automatic Tool Changer Option

The Automatic Tool Changer (ATC) option increases routing efficiency by performing tool

changes during a routing job. A rotating turret holds up to 10 tool holders with tools that are

automatically swapped in and out of the 10 hp ATC spindle when the job calls for a tool change.

The ATC is attached to the side of the router table, requiring only a couple of square feet of

additional floor space. It can be added in the field.

Loading...

Loading...