Troubleshooting

Potential failures and troubleshooting

5

VOLISTA

IFU 01781 EN 19

87 / 106

5.2 Potential failures and troubleshooting

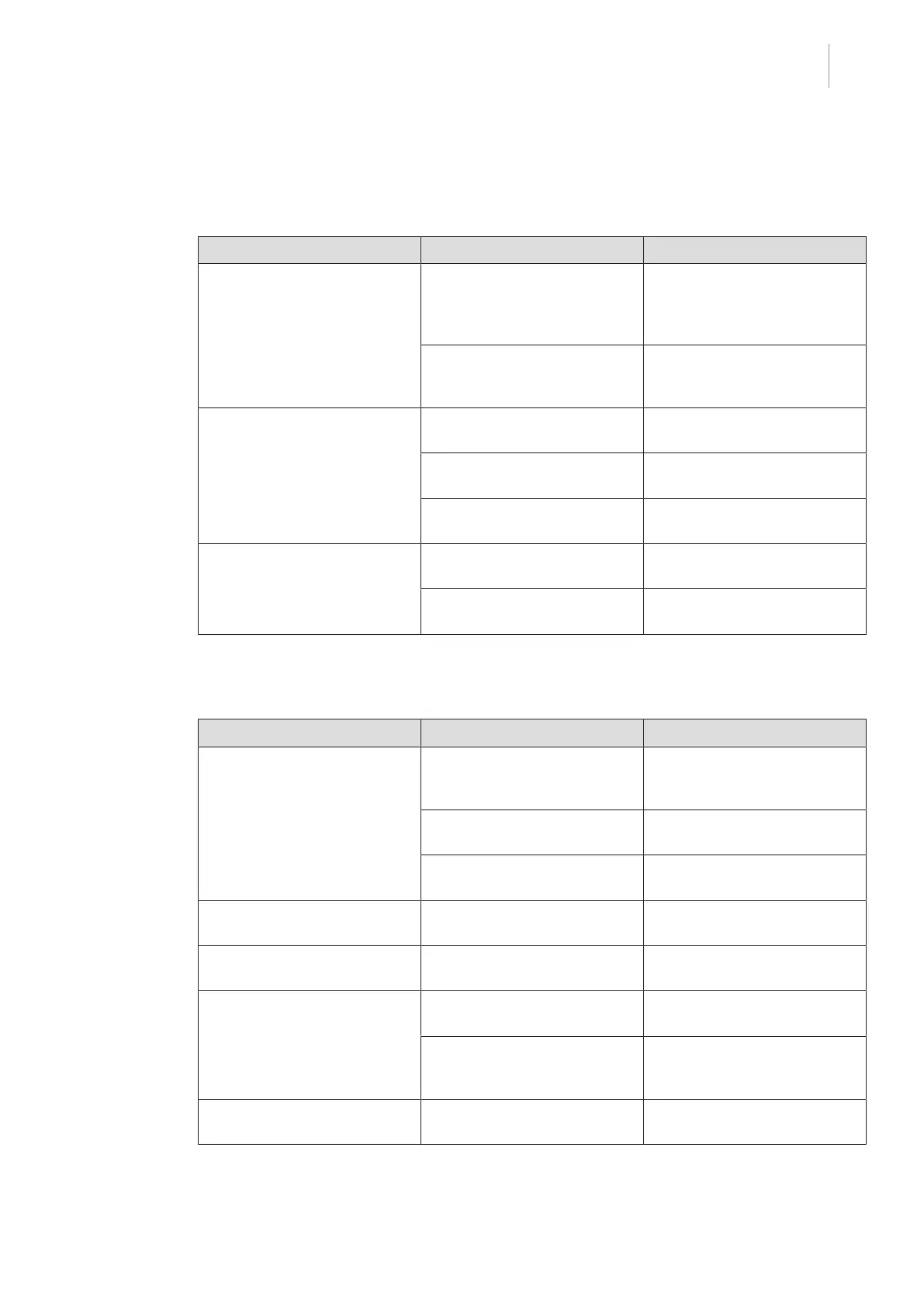

Mechanical components

Problem Likely cause Corrective action

The sterilisable handle does

not click into place correctly

Sterilisation parameters (tem-

perature, time) exceeded

Check the operation of the

handle and in particular the

locking mechanism (audible

click).

The maximum handle service

life has expired or the handle

is twisted or bent.

Replace the handle

The lighthead drifts Suspension tube not vertical Check tube verticality and ceil-

ing structure

Load-bearing structure un-

stable

Contact the Getinge technical

department

Locking screw incorrectly ad-

justed.

Have the locking screw adjus-

ted by a trained technician

Lighthead moves too easily or

is difficult to move.

Locking screw incorrectly ad-

justed.

Have the locking screw adjus-

ted by a trained technician

Insufficient lubrication Contact the Getinge technical

department

Tab.23: Mechanical anomalies and malfunctions

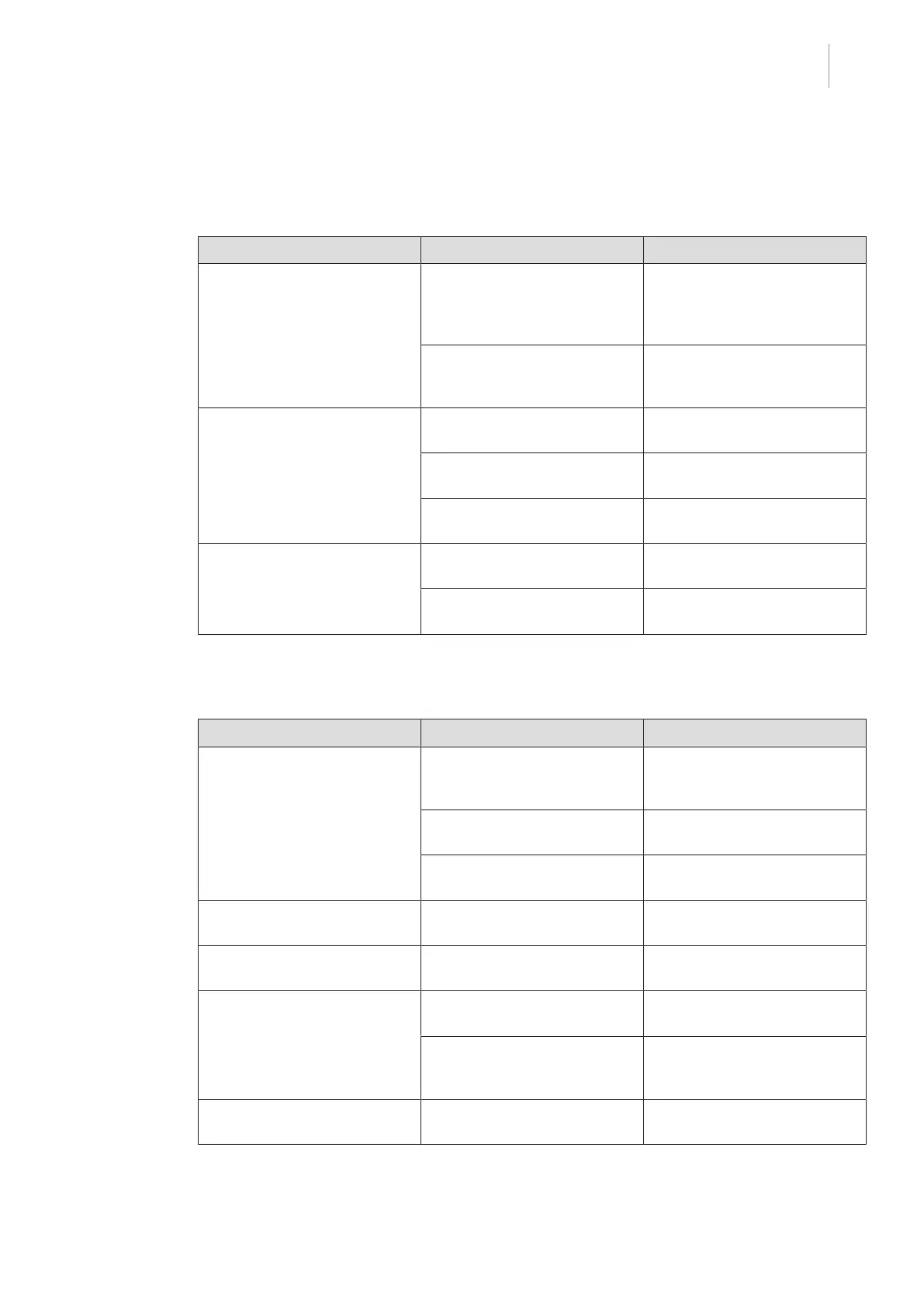

Light system

Problem Likely cause Corrective action

The lighthead does not turn

on.

Power cut Check if other devices on the

same supply network are oper-

ating

Does not switch over to

backup

Contact the Getinge technical

department

Other reason Contact the Getinge technical

department

The lighthead does not turn

off.

Faulty connection between

power supply and lighthead

Contact the Getinge technical

department

None of the lightheads light up Each lighthead has its own

control

Check the LED on the Lexan

panel of each lighthead

A group of LEDs or one LED

does not come on

The LED board or the LED is

defective

Contact the Getinge technical

department

The electronic circuit board

does not communicate with

the LED board

Contact the Getinge technical

department

The light flickers. Incorrectly installed Contact the Getinge technical

department

Tab.24: Optical anomalies and malfunctions

Loading...

Loading...