4-18

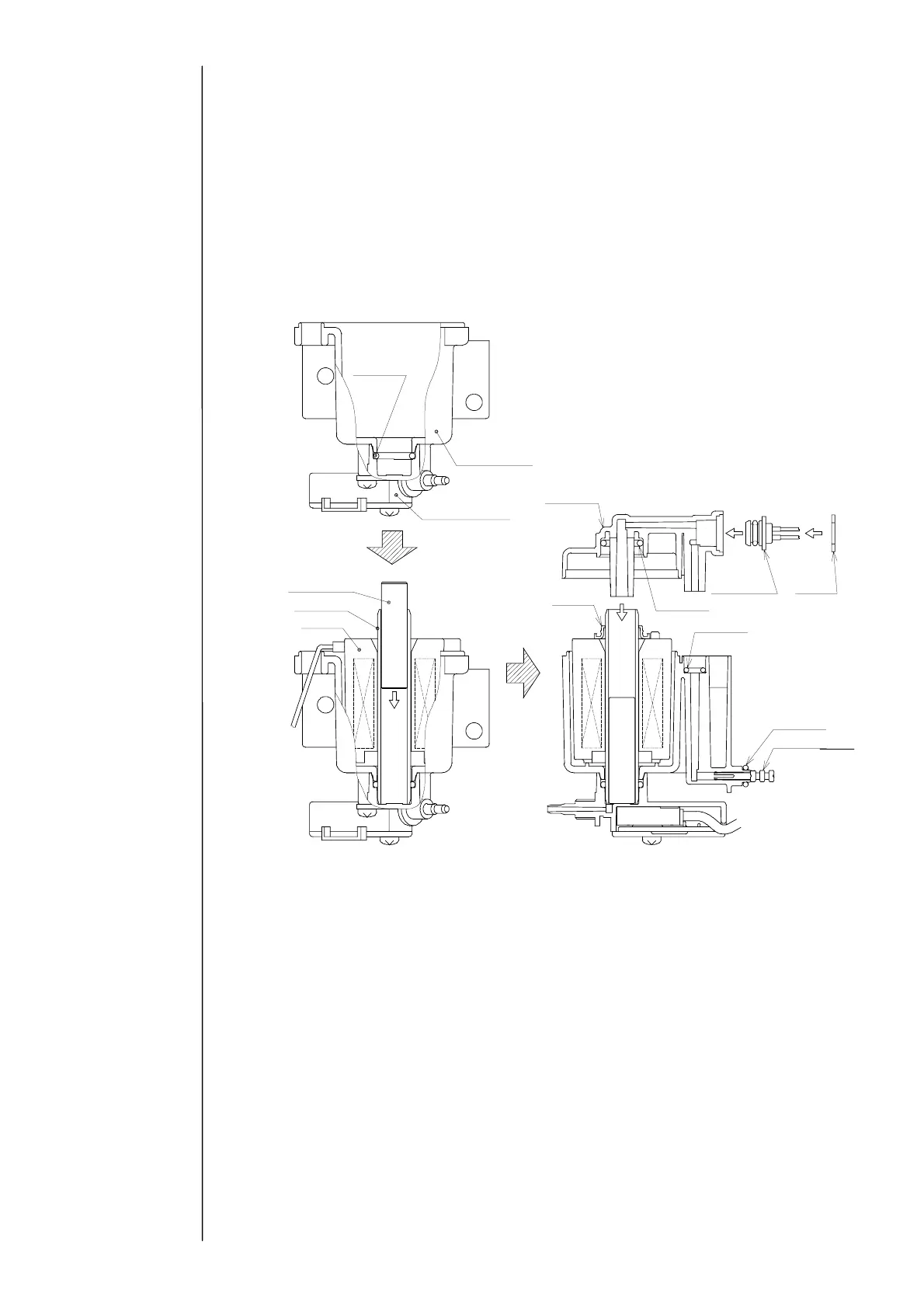

⑥Place the cylinder, the plunger, the viscometer cover, the viscometer IN joint, the

viscometer case and each O-ring into a beaker or the like filled with the makeup ink

and wash them using an ultrasonic washing machine.

“Caution” Do not dip the coil, the thermistor and the proximity sensor in the

makeup ink. It causes trouble.

⑦After the washing, assemble the viscometer in inverse order.

"Caution" To prevent the crack of o-ring, assemble o-ring of the thermistor after

moistening with the makeup ink.

⑧Replace it with new ink and perform the viscometer calibration.

(Ref. 2.6 "Calibration of viscometer)

"Caution" To prevent the crack of o-ring, assemble o-ring of the thermistor after

moistening with thermistor.

⑨Replace it with new ink and perform the viscometer calibration.

(as shown below)

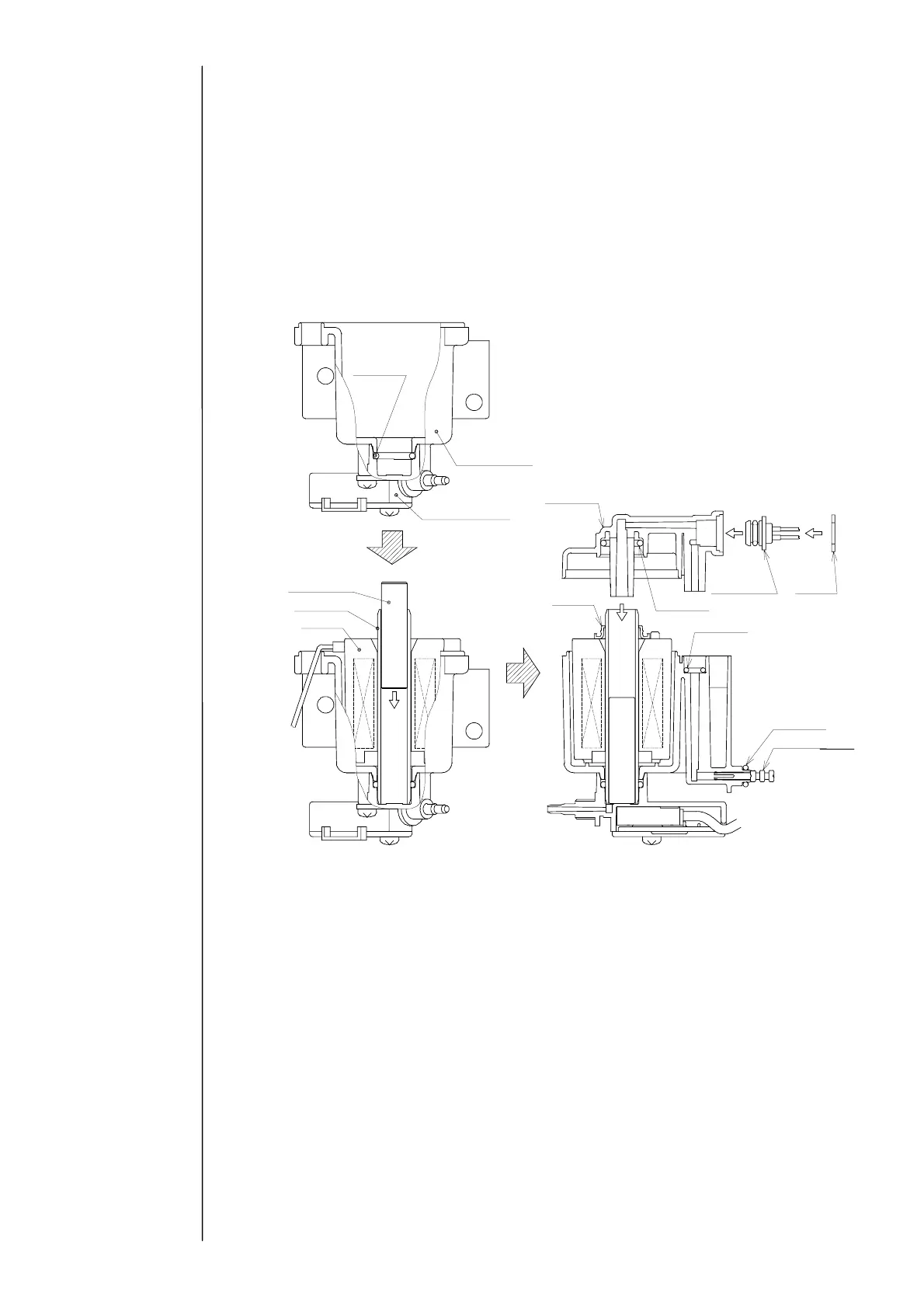

4.9.5 Replacement of the thermistor

①Replace the thermistor as described above.

"Caution" To prevent the crack of o-ring, assemble o-ring of the thermistor after

moistening with thermistor.

O-rin

O-ring

O-ring

O-ring

O-ring

Thermistor

Coil

Cylinder

Plun

er

Viscometer

cover

Viscometer

case

Viscometer IN

oint

Squeezing pin

Fixing

board

Loading...

Loading...