What to do if Intermec Printer's cutter is not responding?

- NNicole NashSep 13, 2025

If your Intermec Printer displays 'Cutter not responding', ensure that the cutter is installed properly.

What to do if Intermec Printer's cutter is not responding?

If your Intermec Printer displays 'Cutter not responding', ensure that the cutter is installed properly.

What to do if Intermec Printer displays Test Cutter not found?

If your Intermec Printer displays 'Test Cutter not found', ensure the cutter is installed properly. A cut-command has been sent but the printer cannot find the cutter.

What to do if Intermec EasyCoder PD41 Printer shows Label not found error?

If your Intermec printer cannot find a label gap or black mark, go into Setup mode and verify that the label length parameter is correct. Also, verify that the Media type settings are correct.

How to fix Intermec Printer showing LSS too high or LSS too low error?

To resolve the 'LSS too high, LSS too low' error on your Intermec printer, load the printer with media, restart the printer in Test mode and select the appropriate media type. For more information, see the EasyCoder PD42 User’s Guide (P/N 934-009-xxx). These errors can occur when you run a testfeed without any media installed, or if you have incorrect media settings.

What to do if there is abnormal function when using Label Taken Sensor on Intermec EasyCoder PD41?

If you experience abnormal function when using the Label Taken Sensor (LTS) on your Intermec Printer, check the following: * Verify if the LTS sensor is working. * Ensure media is loaded properly.

What to do if the label could not feed or abnormal cutting occurs when using cutter on Intermec EasyCoder PD41 Printer?

If the label could not feed or abnormal cutting occurs when using the cutter on your Intermec Printer, check the following: * Ensure the cutter is installed properly. * Check if paper feed rods are sticky. Clean if necessary using isopropyl alcohol.

How to fix weak printout on Intermec EasyCoder PD41?

If the printout from your Intermec Printer is weak, check the following: * Density setting. * If the thermal printhead needs cleaning. * Printhead pressure. * Printhead dot line position.

What to do if the label was not cut straight when using cutter on Intermec Printer?

If the label was not cut straight when using the cutter on your Intermec Printer, ensure that the media is loaded correctly.

How to fix uneven darkness across media path on Intermec EasyCoder PD41 Printer?

If you're experiencing uneven darkness across the media path with your Intermec Printer, check the printhead balance.

Why Intermec Printer is skipping pages when printing?

If your Intermec Printer is skipping pages during printing, try these solutions: * Perform a Test Feed or check your Media Settings. * Check the label gap sensor for any disturbances caused by media or dust.

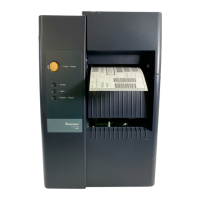

Provides a detailed overview of the EasyCoder PD41 printer's features and capabilities.

Instructions for safely unpacking the printer and its included accessories.

Details on locating and understanding the machine and serial number labels on the printer.

Illustrates and labels the front panel components of the EasyCoder PD41 printer.

Explains the function of the front panel LEDs and the Print button.

Diagram showing the rear panel of the printer and its various ports and connectors.

Details the available connection sockets on the rear of the printer.

Illustrates the internal media compartment of the printer.

Diagram showing the internal print mechanism of the printer.

Step-by-step guide for setting up and connecting the printer.

Guidance on connecting the printer via USB, Serial, Network, or Parallel interfaces.

Procedure to print a test label for verifying printer functionality and configuration.

Instructions for loading various types of media into the printer.

Describes how to use the printer for manual tear-off of printed labels.

Explains the procedure for self-adhesive labels where the liner is separated.

Step-by-step guide for loading thermal transfer ribbon into the printer.

Details the printer states indicated by LEDs and the functions of the Print button.

Provides recommendations for regular inspection and care of the printer.

Instructions on how to clean the printer's printhead to maintain print quality.

Guidance on cleaning the printer's media compartment to prevent jams.

Instructions for cleaning the exterior of the printer to prevent dust ingress.

Lists common printer operation issues and their potential solutions.

Details issues affecting print quality and how to resolve them.

Explains the meaning of the Ready-to-Work LED status and troubleshooting tips.

Provides detailed solutions for common printer adjustments and issues.

Guides on how to adjust ribbon tension and shield to prevent wrinkling.

Step-by-step instructions for clearing media jams from the print mechanism.

Covers adjustments for printhead balance, pressure, and dot line alignment.

Instructions for adjusting the label gap sensor position for accurate media detection.

Describes the printer's startup process and how firmware affects it.

Methods for modifying printer configuration via PrintSet, Home Page, or Command Line.

Explains how to use Testmode and Extended Testmode for diagnostics and setup.

Procedure for downloading and installing the latest printer firmware updates.

Lists detailed technical specifications, including physical dimensions and power.

A comprehensive table detailing the printer's physical, power, printing, and firmware specs.

Specifies the required dimensions for media rolls, including core and roll diameter.

Details the required dimensions for thermal transfer ribbon rolls.

Describes various paper types and their specific width and length requirements.

Specifies media width and paper type setup for non-adhesive strips.

Details media width, liner requirements, and setup for self-adhesive strips.

Covers media width, liner, label width, length, and gap specifications for labels.

Specifies dimensions and detection requirements for tickets with gaps.

Details specifications for tickets and marks used for detection.

Overview of setup parameters and how they affect printer behavior.

Configuration options for serial communication parameters like Baud Rate and Parity.

Parameters controlling media feed before and after printing, including Start and Stop Adjust.

Parameters for configuring media size, type, and print window settings.

Settings related to print speed, contrast, and testfeed modes.

Overview of setup parameters for IPL firmware and their functions.

Information on printing test labels for software, hardware, and network settings.

Configuration of serial communication parameters for IPL firmware.

Parameters for media characteristics like type and sensitivity number.

Settings for emulation, print speed, cutter, and label taken sensor.

Procedure to restore printer settings to factory defaults.

Details the RS-232 serial interface, protocol, and pinout.

Information on using the USB interface, including driver requirements.

Describes the EasyLAN Ethernet interface, its speed, and status LEDs.

Details the Parallel IEEE 1284 interface and its pinout.

Adds network capability to the printer.

Adds a parallel port to the printer.

Enables cutting of continuous paper stock or liner between labels.

Device for peel-off operation and rolling up label batches.

Replacement or complete kit for 203dpi or 300dpi printheads.

| Print technology | Direct thermal |

|---|---|

| Maximum resolution | 203 x 203 DPI |

| Standard interfaces | RS-232, USB 2.0 |

| Internal memory | 16 MB |

| Power requirements | 100-240 VAC ±10%, 45-65 Hz |

| Media thickness | 2.3 - 9.8 mm |

| Maximum label width | 104 mm |

| Maximum label length | 0.15 m |

| Maximum roll diameter | 213 mm |

| Maximum internal memory | 1 GB |

| Supported network protocols | TCP/IP, LPR/LPD, FTP, BOOTP, DHCP, HTTP, SNMPv3, SMTP, SNMP-MIB II |

| Operating temperature (T-T) | 40 - 104 °F |

| Operating relative humidity (H-H) | 20 - 85 % |

| Depth | 453 mm |

|---|---|

| Width | 273 mm |

| Height | 270 mm |

| Weight | 13000 g |