MAINTENANCE

7-106

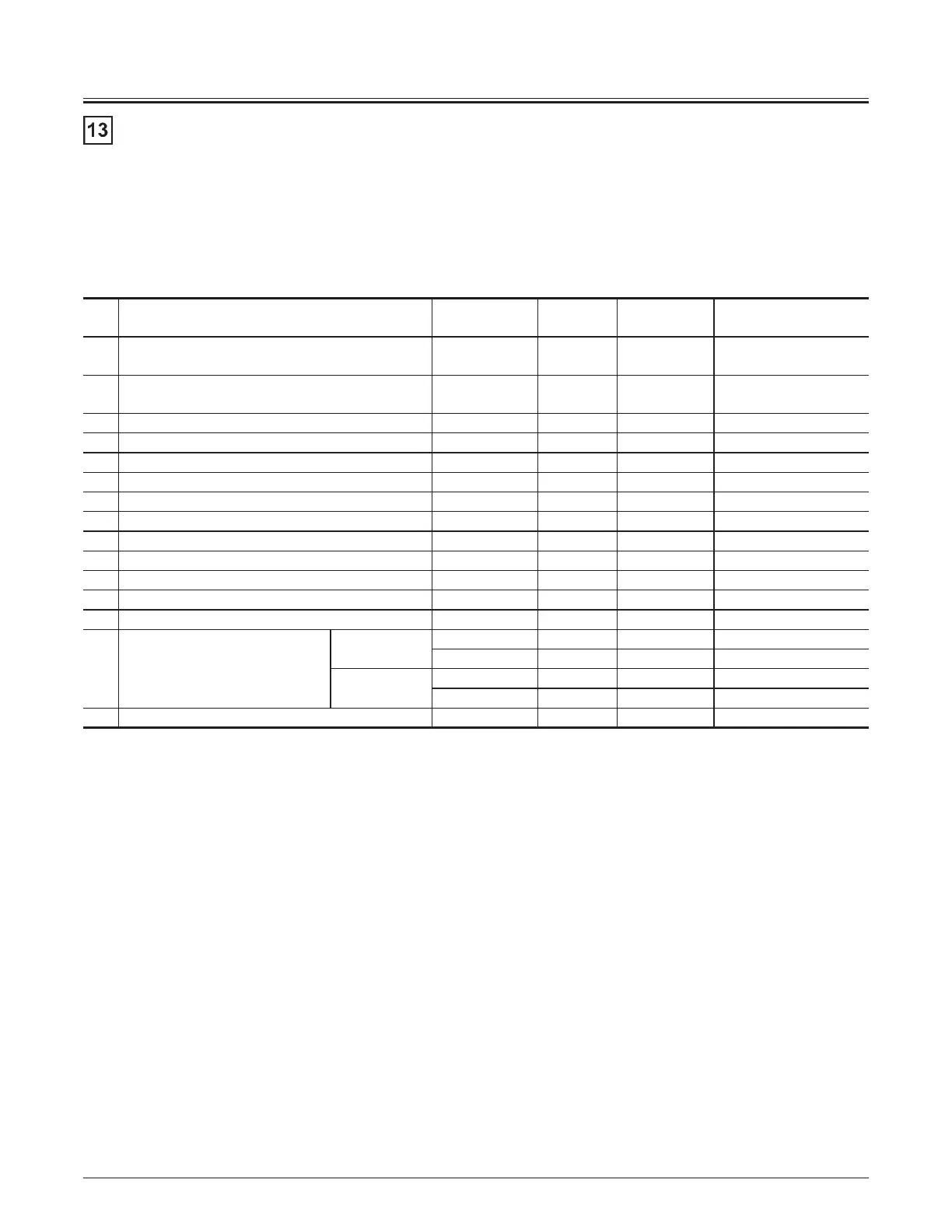

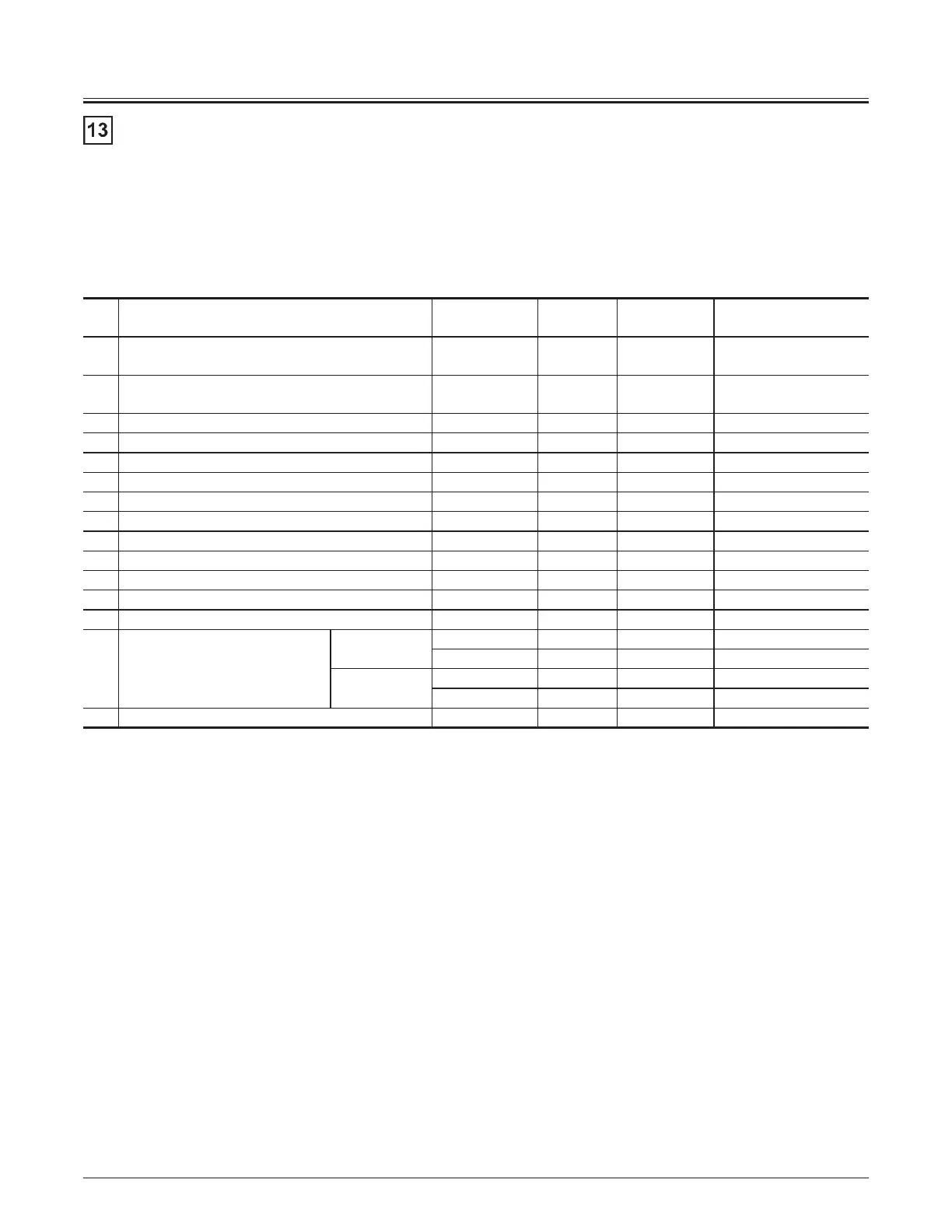

Tightening and Retightening Torque of Nuts and

Bolts

--- every 2000 hours (50 hours at first time only)

Tighten or retighten nuts and bolts used on this machine in

accordance with the torque values shown in the following

table. Check nuts and bolts for looseness and missing daily

before and after operation. If any loose or missing nuts and/or

bolts are found , retighten or supply replacement parts. Check

No. Locations Bolt Diameter Quantity Wrench Size

Torque

N·m (kgf·m, lbf·ft)

1 Front axle mounting bolt 24 8 36

785±150

(80±15, 580±110)

2 Rear axle support mounting bolt 24 (Nut) 8 36

890±170

(90±17, 655±125)

3 Wheel rim mounting bolt 24 60 36 890 (91, 655)

4 Propeller shaft mounting bolt * 12 20 17 143 (15, 105)

5 Propeller shaft support bearing mounting bolt 20 2 30 206 (21, 152)

6 Transmission mounting bolt: Bracket * 20 4 30 401 (41, 296)

7 Transmission mounting bolt: Cushion rubber 18 2 27 315 (32, 230)

8 Engine mounting bolt: Bracket * 12 6 19 81.2 (8.3, 60)

9 Engine mounting bolt: Cushion rubber 18 2 27 315 (32, 230)

10 Muffler mounting bolt 10 8 17 50 (5, 37)

11 Counterweight mounting bolt * 30 4 46 1510 (154, 1115)

12 Top center pin upper flange lock 16 7 24 205 (21, 152)

13 Bottom center pin lock 16 1 24 210 (21, 155)

14 Loader front pin lock

70Z7

16 9 24 210 (21, 155)

12 4 19 90 (9, 66)

70TM7

12 22 19 90 (9, 66)

16 14 24 210 (21, 155)

15 Steering cylinder pin lock 12 4 19 90 (9, 66)

* Apply "LOCTITE® 262" to the threads.

tightness after the first 50 hours then every 2000 hours.

The nuts and bolts other than those shown in the table

below shall be tightened in accordance with the torque

values shown in the table on page 7-107.

Loading...

Loading...