Model 6485 Picoammeter Instruction Manual Measurement Concepts 2-11

Cleaning tips:

• Use dry nitrogen gas to clean dust off connector and terminal insulators, DUT, and

other test circuit components.

• If you have just built the test fixture, remove any solder flux using methanol along

with clean foam-tipped swabs or a clean soft brush. Clean the areas as explained in

the next tip.

• To clean contaminated areas, use methanol and clean foam-tipped swabs. After

cleaning a large area, you may want to flush the area with methanol. Blow dry with

dry nitrogen gas.

• After cleaning, the test fixture (and any other cleaned devices or test circuits) should be

allowed to dry in a 122° F (50° C) low-humidity environment for several hours.

Input protection

Model 6485 incorporates protection circuitry against nominal overload conditions. How-

ever, a voltage higher than the maximum voltage value for the selected current range, and

the resultant current surge could damage the input circuitry.

NOTE Maximum peak voltage: 220V Peak

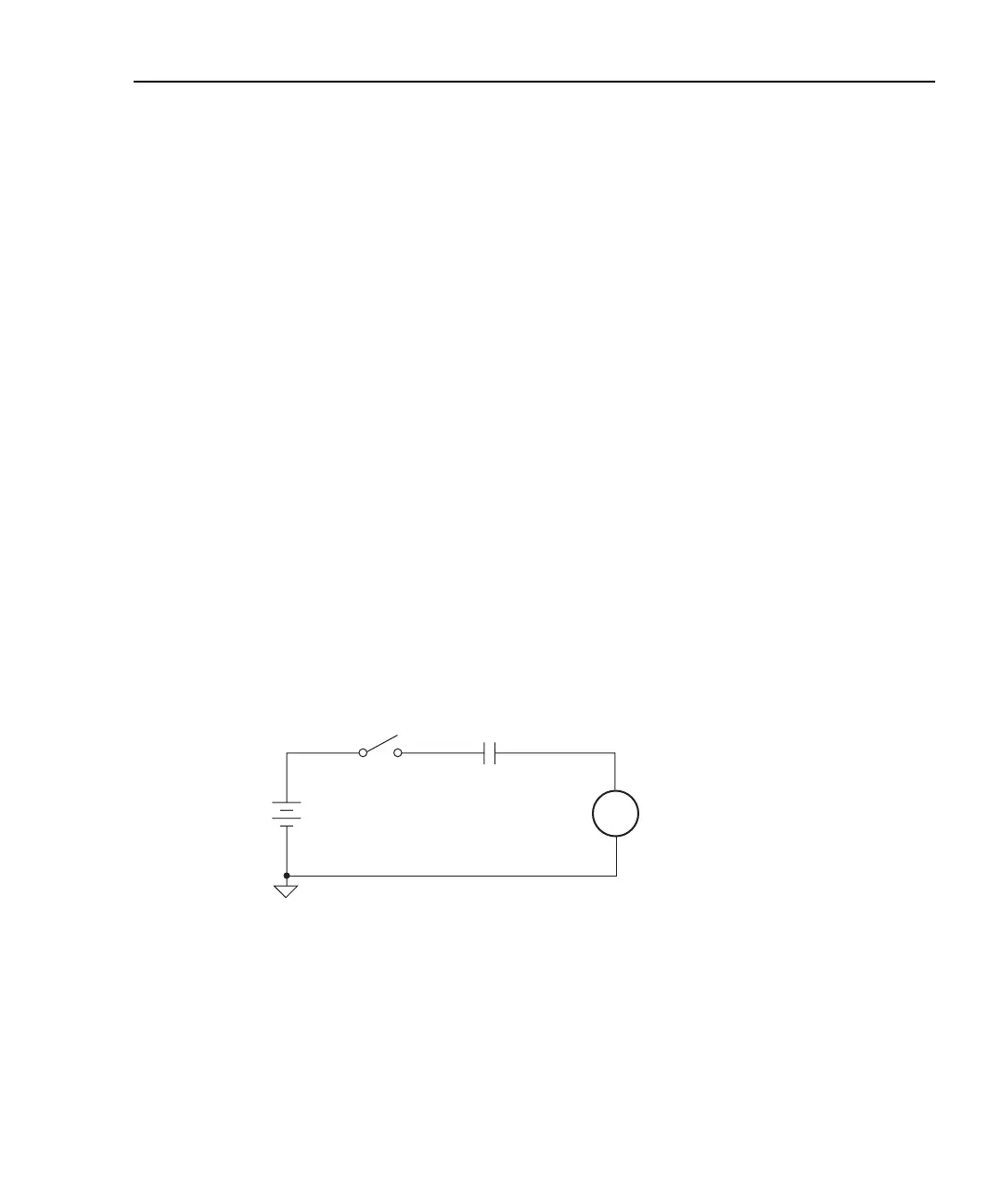

A typical test circuit to measure the leakage current of a capacitor is shown in Figure 2-6.

When Switch S is closed, an initial charging current will flow and the high voltage will be

seen across the input of Model 6485.

Figure 2-6

Capacitor test circuit without protection

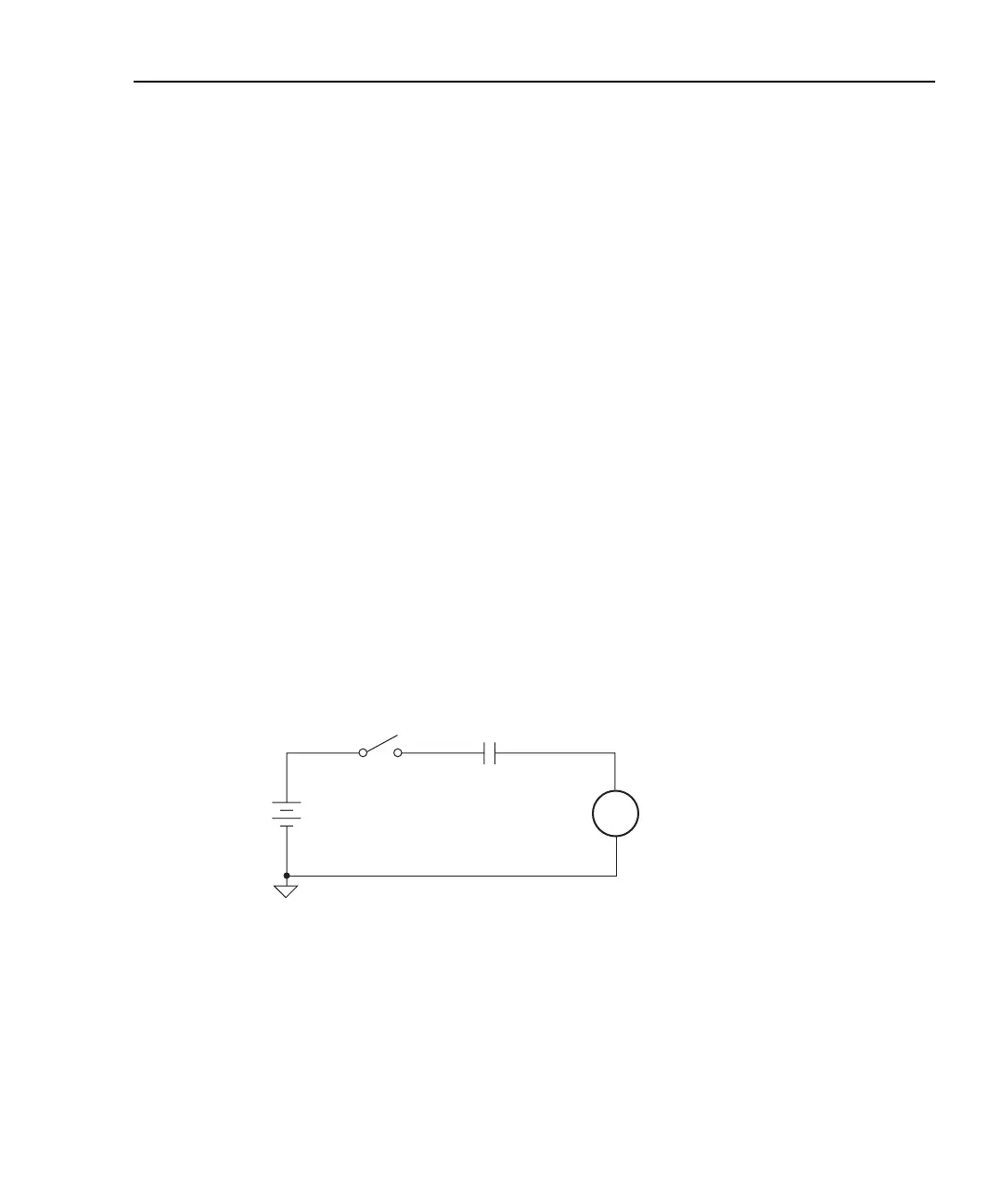

Adding a resistor and two diodes (1N3595) as shown in Figure 2-7 will provide consider-

able extra protection. The resistor must be large enough to limit the current through the

diodes to 20mA or less, and be large enough to withstand the supply voltage. The protec-

tion circuit should be enclosed in a light-tight conductive shield.

Capacitor

Under Test

S

V

6485

Picoammeter

A

Loading...

Loading...