NOTE

• Do not

use an impact wrench. Serious damage

will occur.

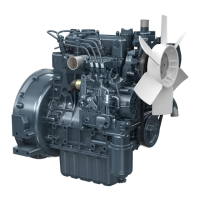

Tools required

• Flywheel stopper

• Flywheel guide screw

1. Set the flywheel guide screw (2).

2. Install the flywheel (1).

3. Attach the flywheel stopper and tighten to the

specified torque.

NOTE

• Apply engine oil to the flywheel screws.

• Check that there are no metal particles that

remain on the flywheel mounting surfaces.

• The flywheel and the crankshaft fit together

in just one position. Make sure they are

securely fit and tighten the screws.

Tightening tor-

que

Flywheel screw

98.10 to 107.9 N⋅m

10.01 to 11.00 kgf⋅

m

72.36 to 79.58 lbf⋅ft

(1) Flywheel (2) Flywheel guide screw

RELATED PAGE

4.30 Measuring angular deviation between crankshaft

T.D.C. and crankshaft position sensor detected T.D.C.

on page 4-112

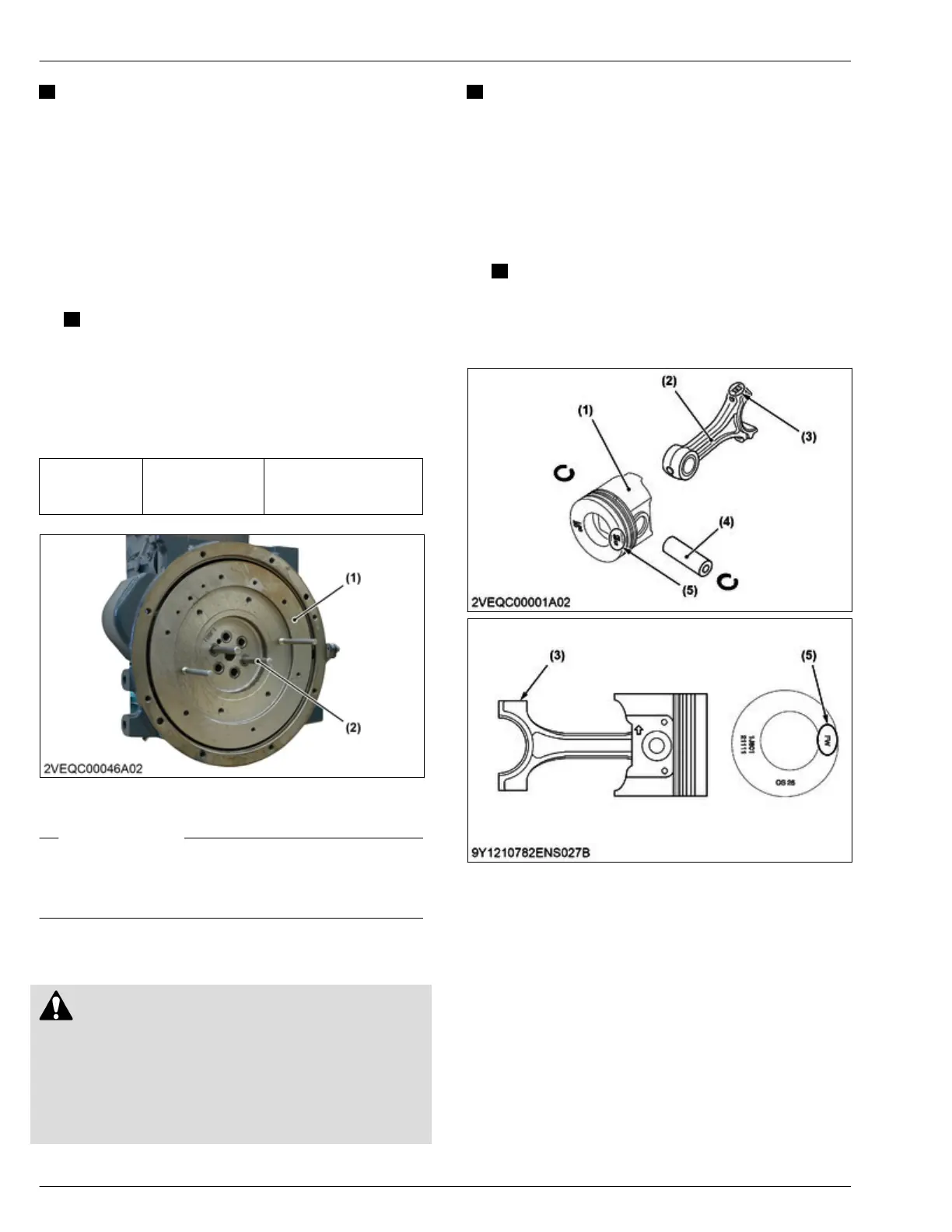

6.9 Assembling piston assembly

CAUTION

• The end

faces of the oil ring are plated with

hard chrome. When you install the piston into

the cylinder, do not give a damage to the

cylinder by the oil ring. If the ring's planting is

scratched, it may get stuck on the cylinder wall,

causing serious damage.

IMPORTANT

• Put a

mark on the connecting rod and the

piston with the same number to keep the same

combination.

1. Put the piston fully in 80 ℃ (176 ℉) oil for 10 to 15

minutes.

2. Install the piston pin (4) and the connecting rod (2)

to the piston (1).

NOTE

• Apply engine oil to the piston pin.

• Align the mark [FW] (5) on the piston to the

flywheel side and the connecting rod mark

(3) to the supply pump side.

(1) Piston

(2) Connecting rod

(3)

Mark

(4) Piston pin

(5) Mark [FW]

4. ENGINE

SERVICING

6. Assembling

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...