214325 95 Revision A

4.7 Checking and Adjusting Knife Hold-Downs

NOTE:

Align guards prior to checking and adjusting hold-downs. Refer to 6.1.1 Adjusting Knife and Guards, page 276.

Refer to following procedures:

• 4.7.1 Checking Pointed Guard Hold-Downs, page 95

4.7.1 Checking Pointed Guard Hold-Downs

This procedure is applicable to headers with pointed guards.

1. Check guard alignment and adjust as required. Refer to 6.1.1 Adjusting Knife and Guards, page 276.

Measure clearance between hold-downs and knife sections as follows:

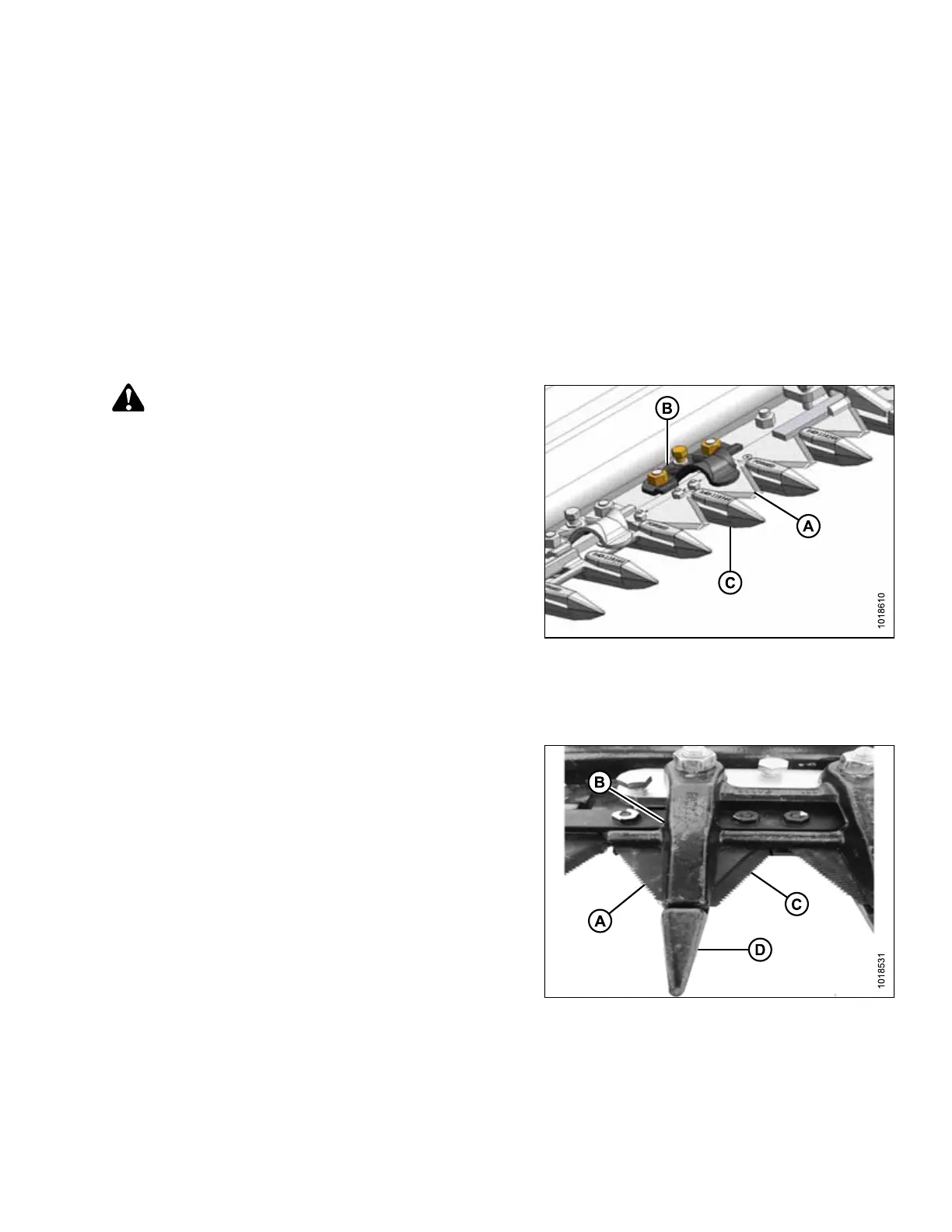

Figure 4.9: Normal Guard Hold-Down

WARNING

To avoid bodily injury or death from unexpected startup

of machine, always stop engine and remove key before

making adjustments to machine.

2. Shut down combine, and remove key from ignition.

3. Manually stroke knife to locate section (A) under hold-

down (B).

4. At standard guard locations, push knife section (A)

down against guard (C) and measure clearance

between hold-down (B) and knife section (A) with a

feeler gauge. The clearance should be 0.1–0.6 mm

(0.004–0.024 in.).

5. If necessary, refer to Adjusting Pointed Guard Hold-

Downs, page 96.

Double-knife:

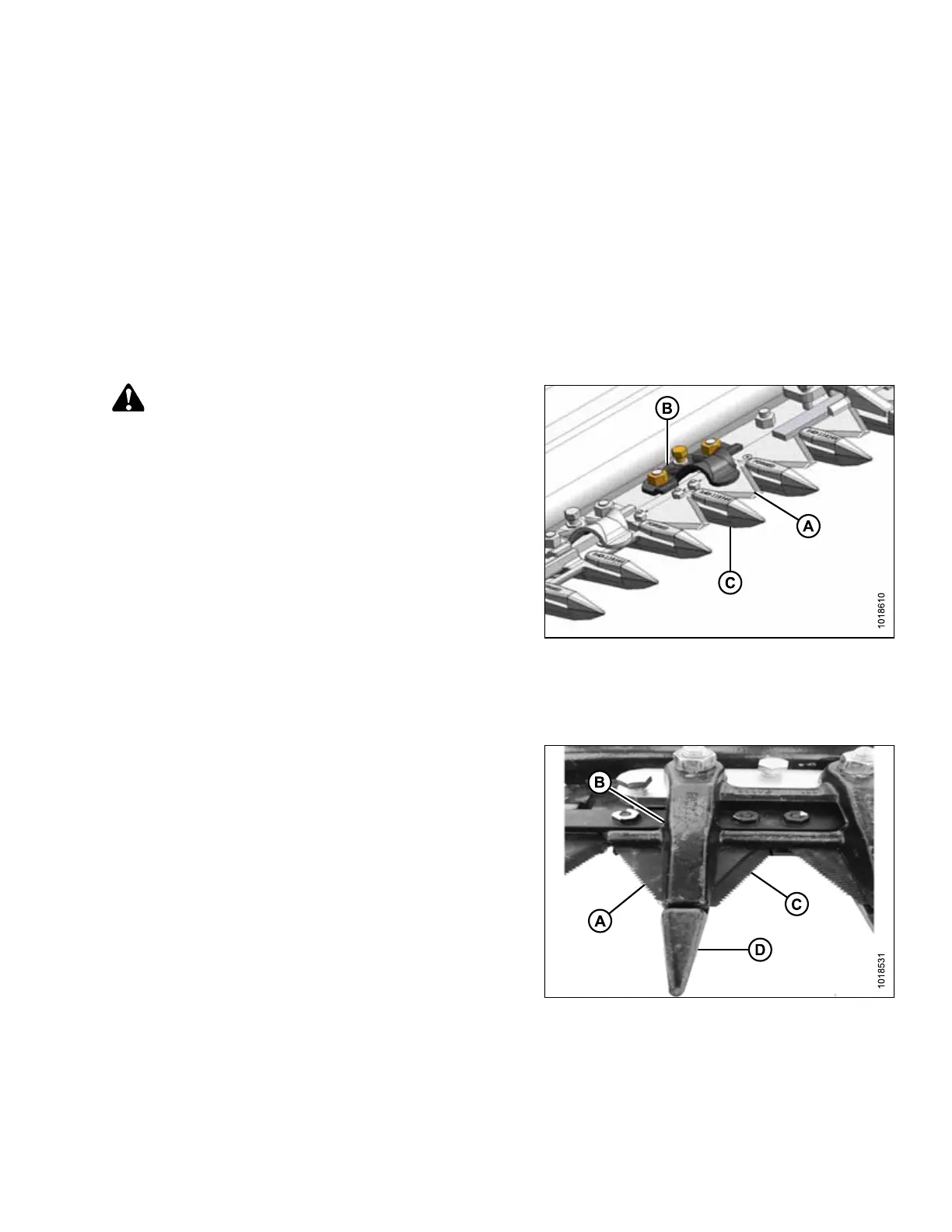

Figure 4.10: Double-Knife Center Guard

Hold-Down

6. Manually stroke knife to locate sections (A) and (C)

under center hold-down (B).

7. Measure between knife sections (A) and (C) with a

feeler gauge. The clearances should be as follows:

• At tip of hold-down: 0.1–0.4 mm (0.004–0.016 in.)

• At rear of hold-down: 0.1–1.0 mm (0.004–0.040 in.)

8. If necessary, refer to Adjusting Hold-Down at Double-

Knife Center Pointed Guard, page 96.

PERFORMING PREDELIVERY CHECKS

Loading...

Loading...