214325 129 Revision A

4.18.2 Lubrication Points

Refer to illustrations on following pages to identify various locations that require lubrication.

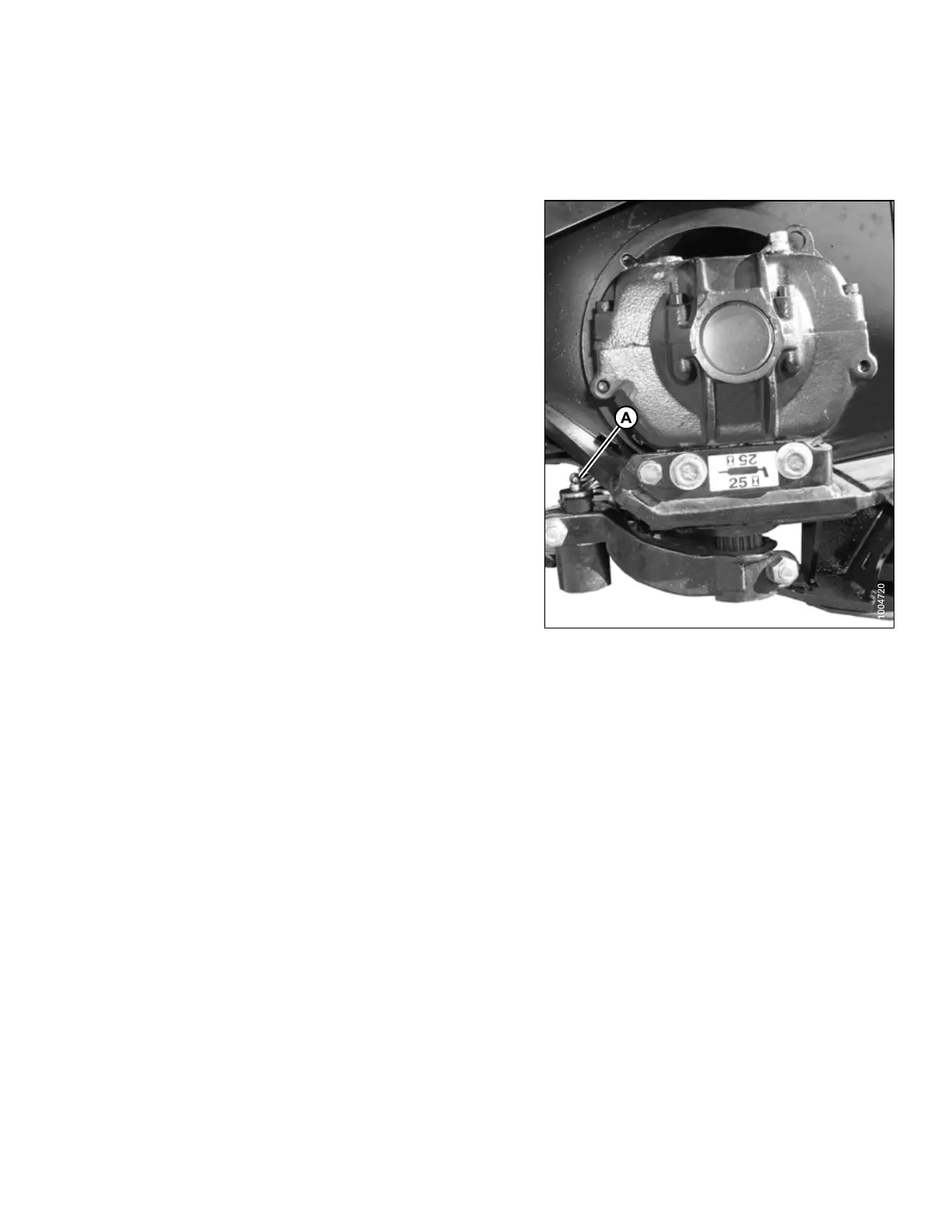

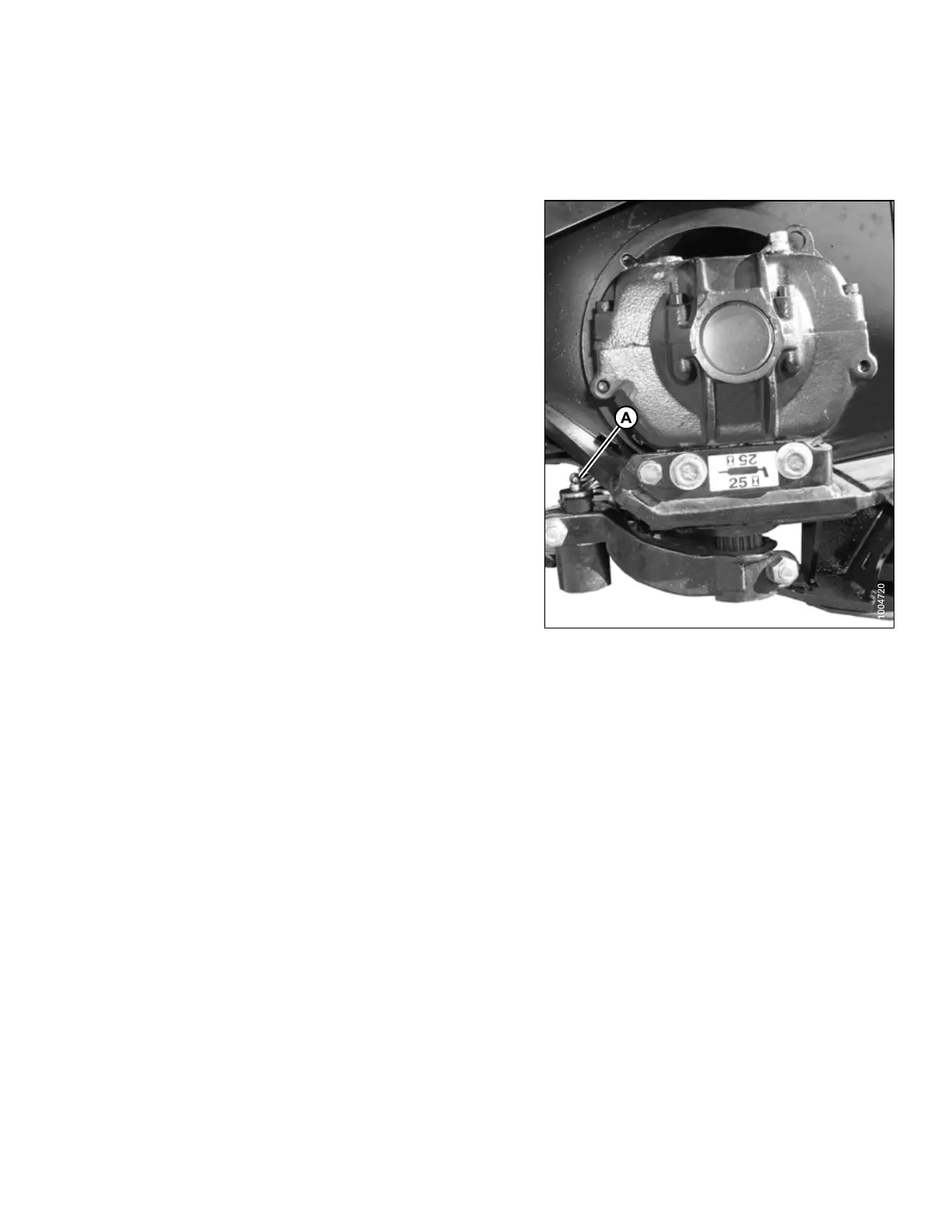

Knifehead

Figure 4.78: Knifehead

Single Knife – 1 Place

Double Knife – 2 Places

IMPORTANT:

Overgreasing can cause knife to bend and make contact

with guards closest to knifehead. Check for signs of

excessive heating on first few guards after greasing. If

required, relieve some pressure by removing grease

fitting.

• To prevent binding and/or excessive wear caused by

knife pressing on guards, do NOT over grease

knifehead (A).

• Apply only 1–2 pumps of grease with a grease gun, or

just until knifehead starts to move away from arm. Do

NOT use an electric grease gun.

• If more than 6–8 pumps of grease gun are required to

fill cavity, replace seal in the knifehead.

• Check for signs of excessive heating on first few

guards after greasing. If required, relieve pressure by

pressing check-ball in grease fitting.

NOTE:

Use high temperature extreme pressure (EP2) performance with 1% max Molybdenum Disulphide (NLGI grade 2)

Lithium base grease unless otherwise specified.

PERFORMING PREDELIVERY CHECKS

Loading...

Loading...