EMISSION SOLUTION AND CONTROL

AFTERTREATMENT, MACK

CAUTION

Do not perform active regeneration, if the

vehicle is located in a hazardous location.

If the vehicle is located in such a location,

stop the regeneration by pushing the DPF

switch to the "Stop Regeneration"

position. If active regeneration is stopped,

restart when the vehicle is in a safe

location. However, if active regeneration is

stopped repeatedly, take the vehicle to a

certied service facility. The technician

uses a service tool to initiate the

regeneration.

CAUTION

Use of improper diesel fuel or engine oils

adversely affects performance, efciency,

and durability of the DPF system and the

engine. Engine failure can occur.

Warranties are rendered void due to usage

of improper fuel. Unapproved fuel

additives (including engine oil) are NOT

permitted.

The chassis is equipped with a 2010 or

newer emission-compliant engine, with a

Diesel Particulate Filter (DPF) and

Selective Catalytic Reduction (SCR)

system. Vehicles equipped with a DPF

require EO-O Premium Plus (or VDS-4)

high performance diesel engine oil and

Ultra Low Sulfur Diesel (ULSD) fuel.

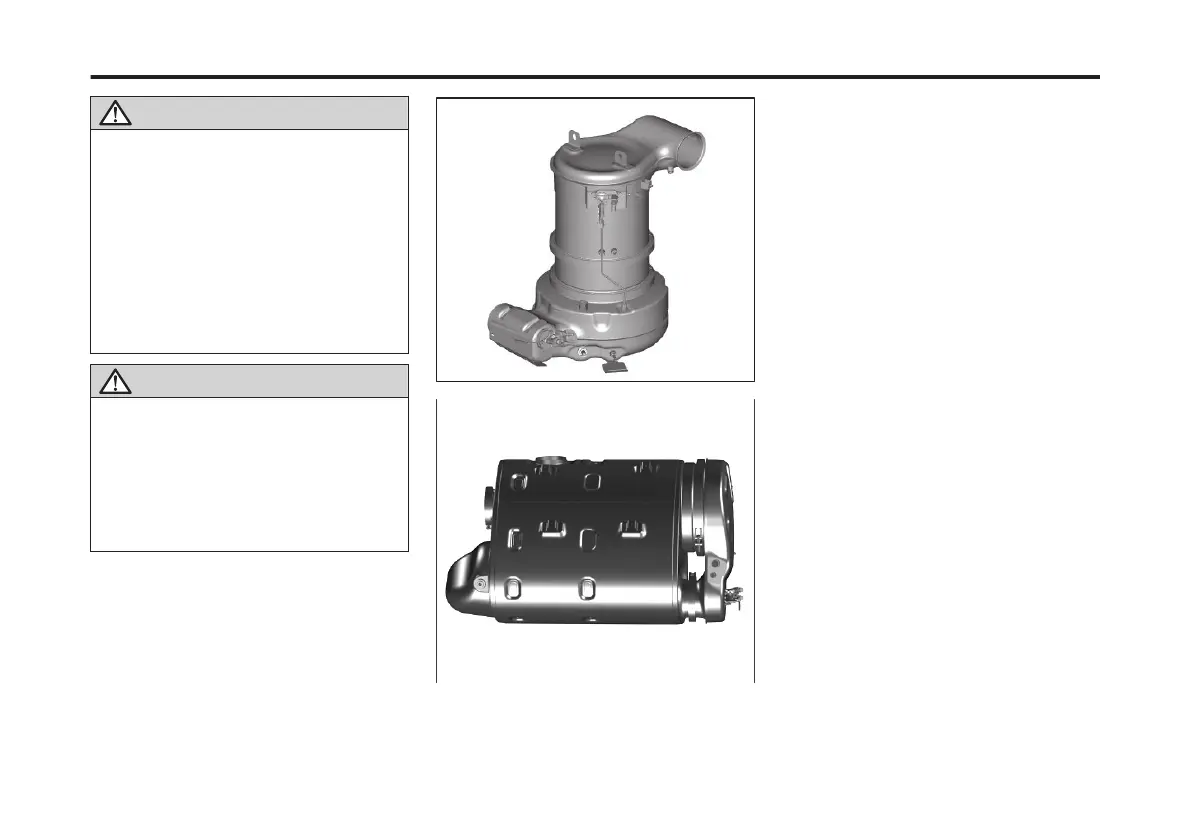

A Diesel Particulate Filter (DPF) takes

the place of the standard mufer. The

DPF is used to meet EPA requirements

to help reduce soot and particulate

emissions into the atmosphere. The

particulates are removed by collecting in

the DPF unit, where they are eventually

oxidized with passive regeneration or

active regeneration of the lter. The

Enginge Control Unit (ECU) and exhaust

aftertreatment system determines when

regeneration is required.

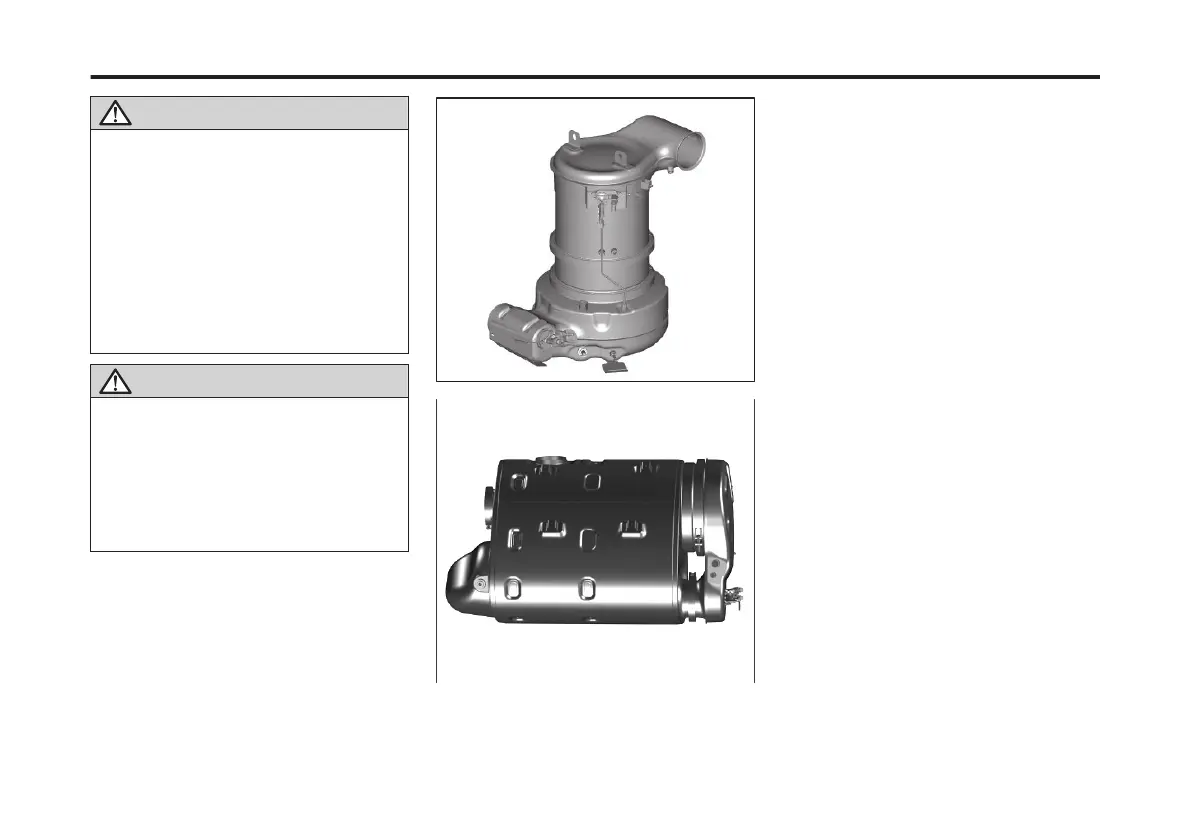

Conventional exhaust aftertreatment

systems use passive and active

regeneration. The passive regeneration

process oxidizes the particulates

captured in the DPF while the vehicle is

in operation. An oxidation catalyst raises

the exhaust temperature to

approximately 260°C (500°F). This

temperature is when a chemical reaction

takes place to oxidize the soot (passive

regeneration).

211

X Publication_PC28

Loading...

Loading...