MAINTENANCE, LUBRICATION AND SERVICE

ENGINE AIR FILTER

NOTE

For recomended intervals, refer to Engine

Maintence Tables in the Engine section of

this manual.

The air cleaner prevents dust, dirt and

other harmful contaminants from

entering the engine through the air

intake system. Maximum engine

protection can only be achieved through

regularly scheduled maintenance

practices that include periodic air intake

system inspections and air lter element

changes.

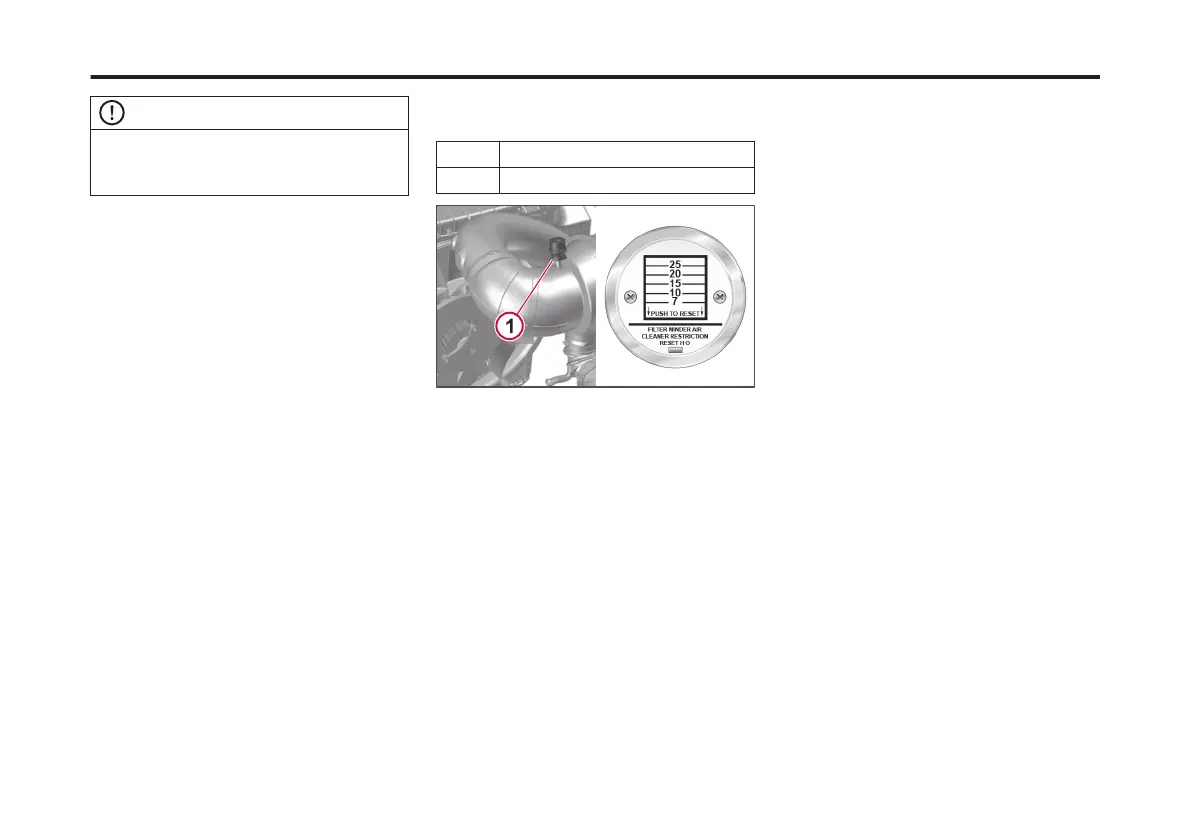

The most efcient method of

determining air lter element change

intervals is by regularly checking the air

lter restriction gauge, which may either

be mounted directly to the air cleaner

canister, on the air cleaner outlet tube or

inside the cab. The restriction gauge

measures the amount of restriction in

the air lter element. Some chassis may

have a dash-mounted dial-type

restriction gauge which measures lter

restriction in mm/inches of water.

Change the air lter element in

accordance with the procedures as

outlined, or the dash-mounted gauge

indicates inlet restriction as follows:

Mounted Gauge Inlet

Restrication Indication

Engine

Milimeters (Inches) Water/KPa

MP7

™

510 (20) /5 kPa

1 Air Filter Restriction Gauge

Damage to the air lter element, such as

holes in the lter media, will give an

inaccurate restriction reading. Therefore,

even if a maximum restriction is not

indicated, the air lter element should be

changed yearly or at recommended

intervals, as described in this manual.

When replacing the air lter element, or

whenever the air inlet system has been

disassembled, inspect the inlet air ducts

between the air cleaner canister outlet

and the turbocharger inlet as follows:

• Inspect the rubber elbows for cracks,

splitting and/or holes. Rubber

components must be exible so that

they conform to the plastic ducts and

ensure a tight seal.

• Inspect plastic ducts for cracks and/or

holes.

• Ensure that all hose clamps are

properly installed and tightened to

specications.

• Make sure the plastic ducts do not rub

against any components such as air

conditioning hoses, wire harnesses, etc.

Filter Element Installation

1

Wipe the air cleaner housing clean.

2

Remove the lter element(s).

3

Inspect sealing areas for dirt tracks

which would indicate that dust has

leaked past the seal. If dirt tracks are

found, the cause must be

determined and corrected.

4

Thoroughly clean the inside of the air

cleaner canister with a damp cloth or

vacuum cleaner.

5

Inspect the sealing areas of the

housing for damage. Repair or

replace as necessary.

6

If equipped with a metal canister,

inspect inside the canister for rust. If

rust is present:

1 Remove the air cleaner canister

from the chassis.

2 Remove all loose rust with a wire

brush or a coarse Scotch Brite pad.

284

X Publication_PC28

Loading...

Loading...