MAINTENANCE, LUBRICATION AND SERVICE

TIRES, WHEELS AND HUB

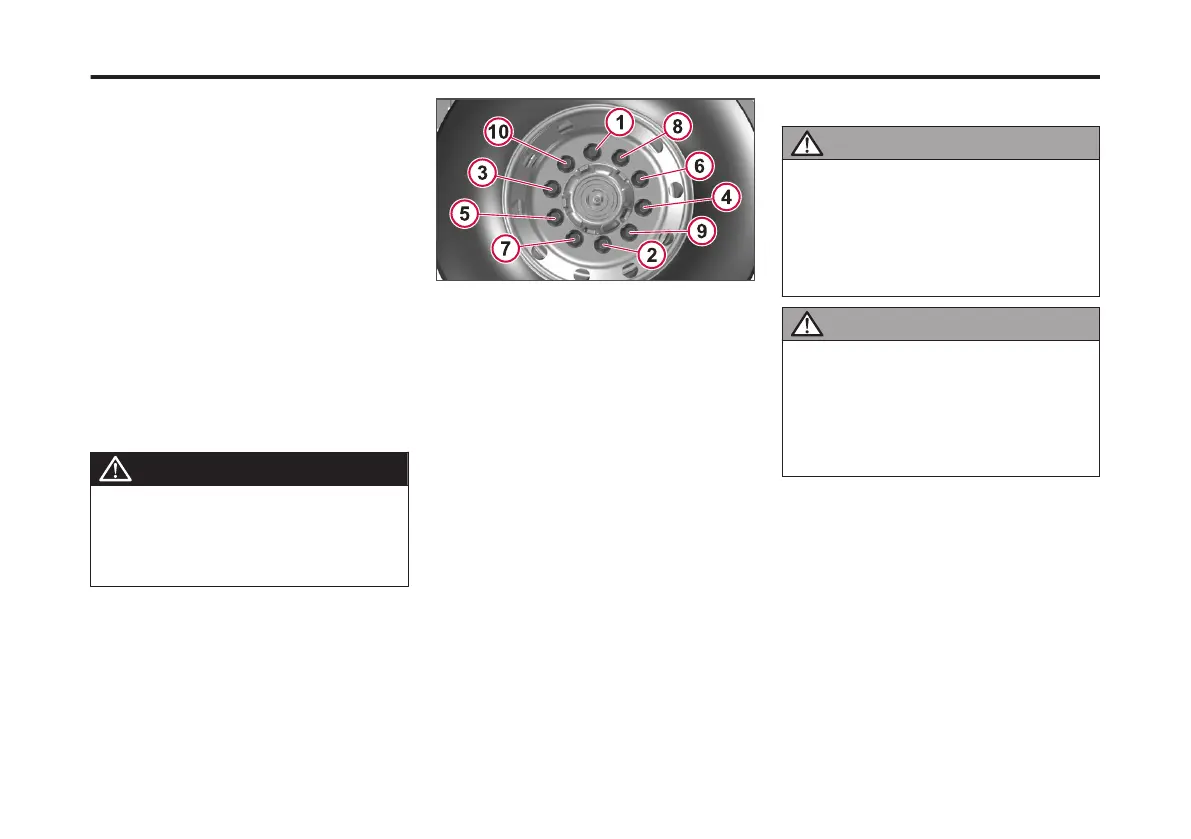

Wheel Nut Tightening

After the initial tightening, retightening

must be made within the rst 800 Km

(500 miles). After the rst retightening,

only normal inspection of nut tightness

is needed.Check front and rear wheel

nut tightness with a torque wrench. All

disc wheels for Mack vehicles have a

tightening torque of 610 Nm (450 lb-ft).

Tighten the nuts in the correct

sequence. Inspect bolts and nuts for

signs of wear or cracks. Make sure that

the bolts are not bent. This tightening

check is particularly important when

rims or brake drums are newly painted.

Paint can ake off from these surfaces,

causing the nuts to lose their grip and

the wheel to loosen.

DANGER

Failure to properly torque-tighten the

wheel nuts can result in the breakage of

wheel studs and the subsequent loss of

wheels. Loss of vehicle control and

serious personal injury or death can occur.

1 1-10 Stud Wheel Nut Tightening Sequence

Tire Wear

WARNING

DO NOT operate the vehicle with under-

inated tires. Always keep your tires

inated to the manufacturers

recommendation. Increased exing in the

tire sidewall produces heat. The heat can

build to the point of blowing the tire out

causing an accident.

WARNING

Check tire pressure when the tire is cold.

Never bleed the air from hot tires.

Increased tire pressure measured in a hot

tire is normal. Low pressures may cause

side wall exing, resulting in increased

heat, leading to tire failure and vehicle

accident.

Remove stones lodged in ribs or in

between double-mounted wheels.

Check the tire pressure and leak-test the

valve stems.

280

X Publication_PC28

Loading...

Loading...