MAINTENANCE, LUBRICATION AND SERVICE

FUEL SYSTEM

• Fuel stored for a long time may

oxidize and form solids, causing

ltering problems.

• Keep the area around the ll cap

clean.

Generally, fuel contamination occurs as

the result of improper fuel handling. The

most common types of contamination

are water, dirt and microbial growth

(black slime). The formation of varnishes

and gums resulting from poor fuel

stability or long storage (stale fuel) also

affects fuel quality. The best treatment

for contamination is prevention by

maintaining a clean storage system and

choosing a reputable fuel supplier.

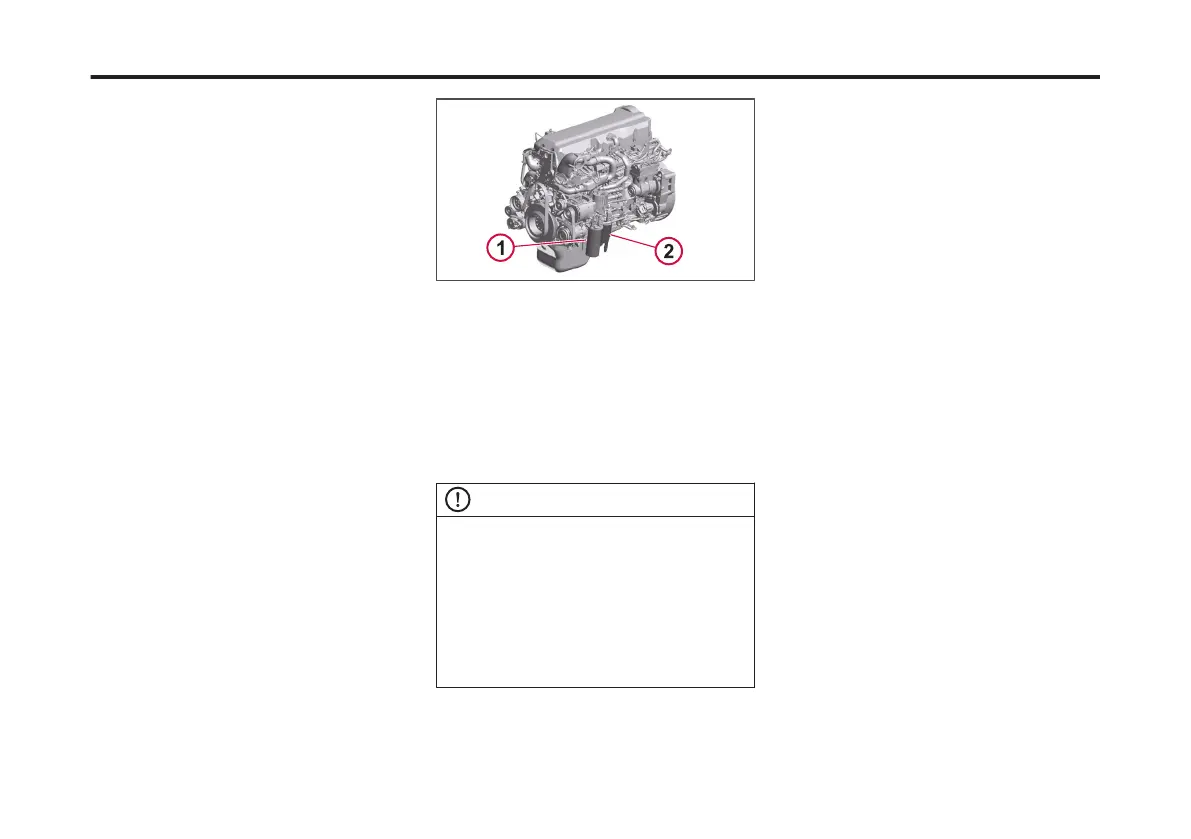

Fuel Filters

A primary fuel lter can be located on

the engine or remote mounted on the

frame rail. This lter consists of a lter

cartridge, a water separation bowl and

may have a fuel heater built in.

The secondary fuel lter is located on

the cold side of the engine, below the

engine electronic control unit (EECU).

The lter is a spin-on lter.

Mack MP engines utilize a spin-on

primary and secondary fuel lter. Both

lters are located on the cold side of the

engine

1 Secondary Fuel Filter

2 Primary Fuel Filter

The primary fuel lter on Mack MP

engines incorporates a plastic water

separator bowl. Additionally, the plastic

bowl includes a water-in-fuel sensor. A

warning lamp on the instrument panel

illuminates when water is detected in the

fuel.

NOTE

There are optional fuel lter systems (such

as Davco, Conmet, etc.) available for

Mack MP engines. These fuel lter

systems use a single remote-mounted

lter, eliminating the spin-on primary and

secondary lters. For service information

concerning these lters, refer to the

specic fuel lter manufacturers service

literature.

275

X Publication_PC28

Loading...

Loading...