MAINTENANCE, LUBRICATION AND SERVICE

DRIVE BELT ROUTING

mark (the shiny area on the pulley where

the belt rides). The witness mark should

be approximately the same width of the

belt.

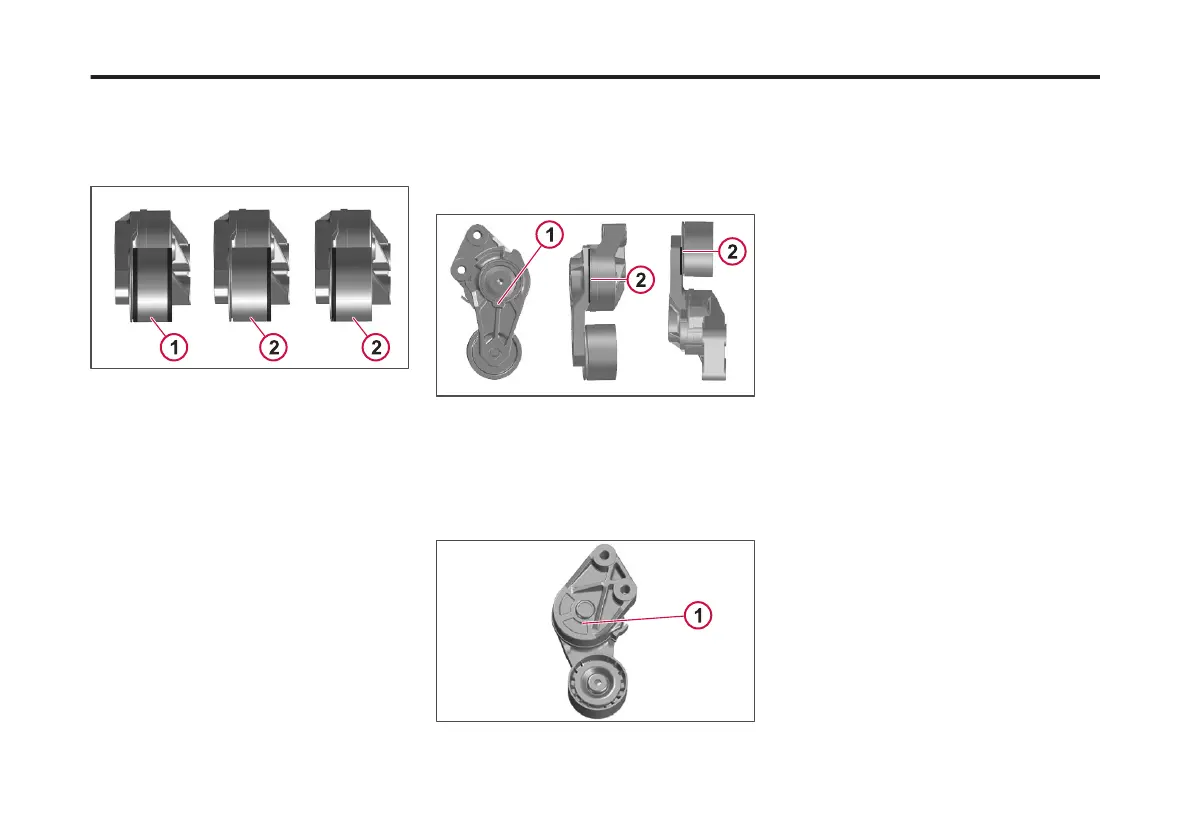

1 Acceptable (Witness Mark Approximately

Same Width as Belt)

2 Not Acceptable (Witness Mark Tracking Off

Edge of Pulley)

Remove the belt by using a 1/2 inch

breaker bar to pull the tensioner back to

the install stop. Slowly return the

tensioner to the free-arm stop.

With the belt removed, use the breaker

bar to slowly pull the tensioner from the

free-arm stop to the install stop and then

slowly releasing it back to the free-arm

stop. Any excessive roughness or

hesitancy noticed while performing this

check indicates that the tensioner must

be replaced.

Check for metal-to-metal contact as

follows:

Check for contact between the arm and

the spring case. Replace if metal-to-

metal contact is seen.

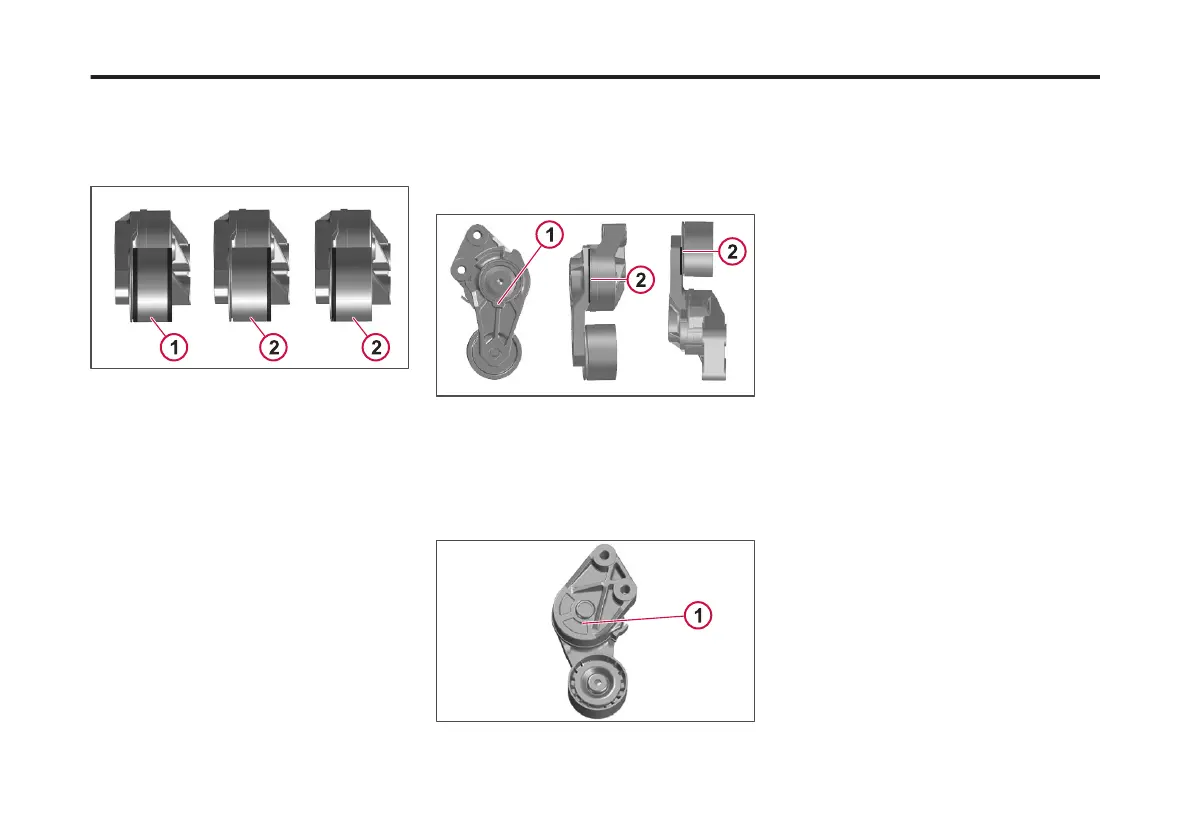

1 Free-Arm Stop Position

2 Contact between Arm and Spring Case

Check.

Check for metal-to-metal contact

between the arm and the end cap.

Replace if contact is seen.

1 Contact between Arm and End Cap Check

266

X Publication_PC28

Loading...

Loading...