Chapter 5 Parameters

86

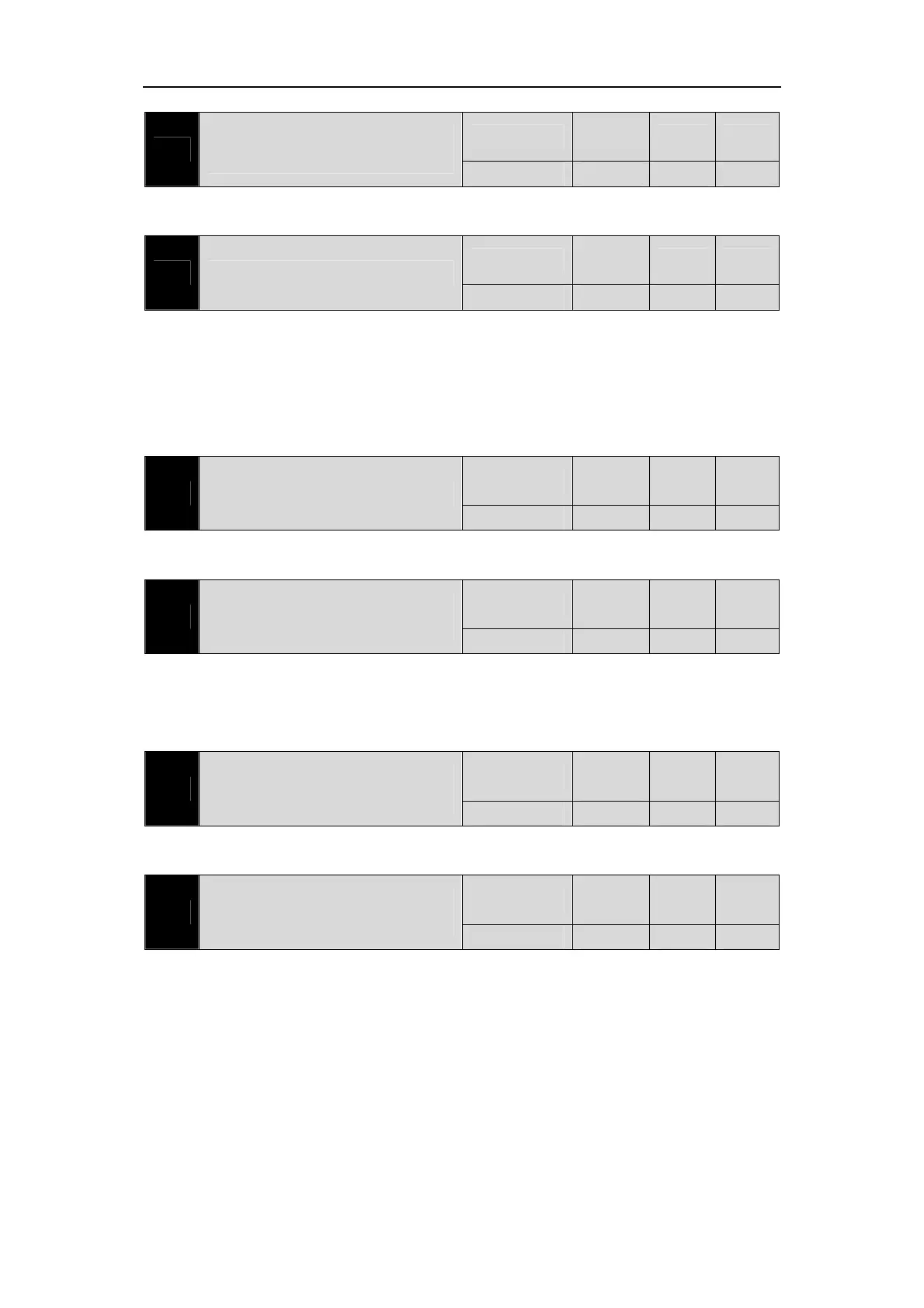

P229

Intermediate frequency vibration

suppression switch

Range

Default

value

Unit Usage

0~2 0 P

Parameter meaning:

0: Invalid 1: Manual setting 2: Automatic setting

P270 Model tracking control switch

Range

Default

value

Unit Usage

0~3 0 P

It is suggested that Fn1 function should be used to deduce the load inertia first.

Suitable for position control, select appropriate parameters according to different loads,

can improve the response of the system.

Parameter meaning:

0: Model tracking is invalid 1: Applicable to rigid load

2: Suitable for flexible load 3: General purpose

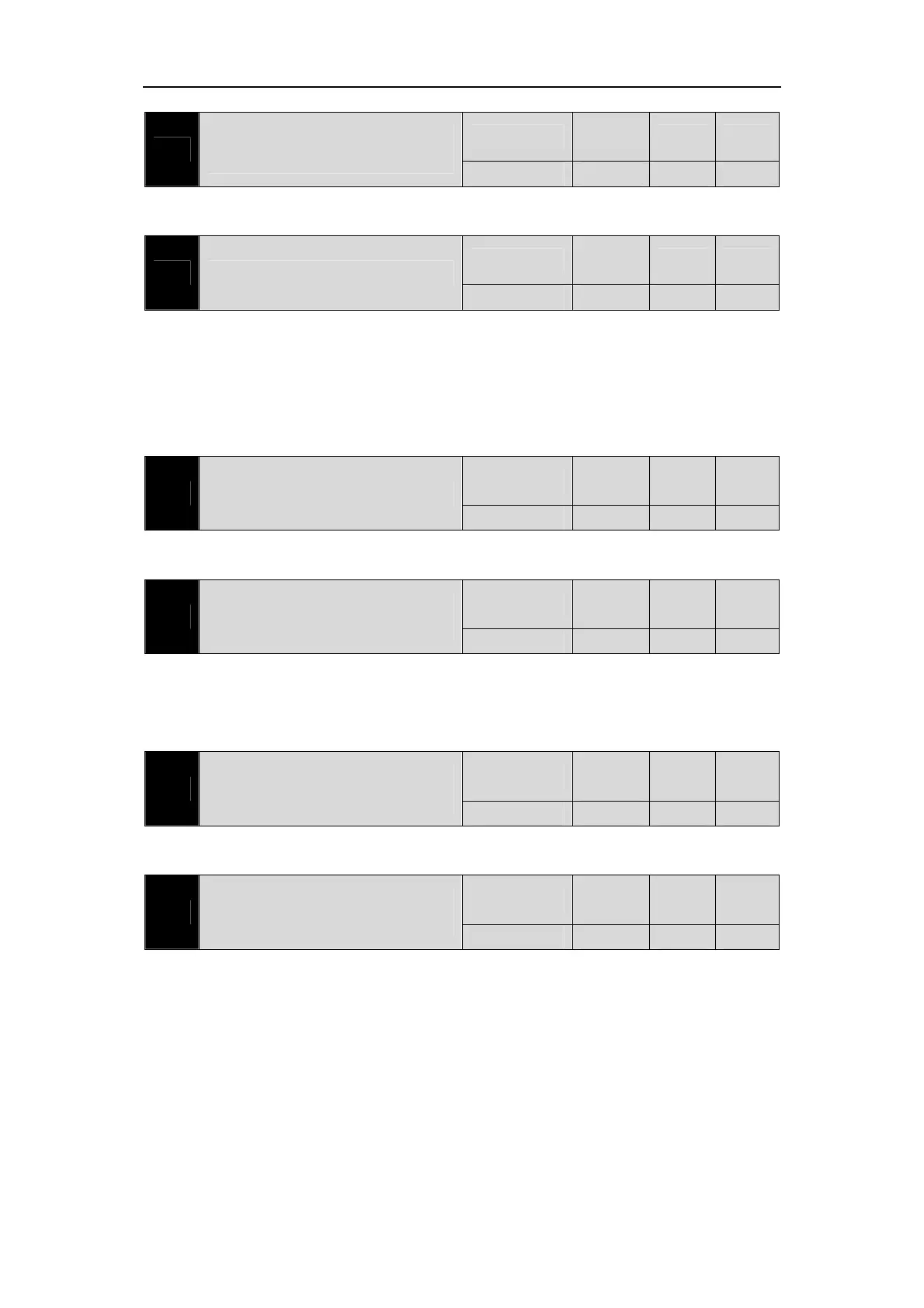

P271 Model tracking control gain

Range

Default

value

Unit Usage

10~2000 40 Hz P

Model tracking control gain, modes 1 ~ 3 are valid.

The higher the value, the faster the response, too much may bring noise.

P273

Model tracking positive direction

proportional control

Range

Default

value

Unit Usage

0~1000 100 % P

Model to trace the positive direction control deviation, mode 1 ~ 3 are valid.

By adjusting this parameter, the forward and reverse response speed can be adjusted

separately.

The larger the value is, the greater the feedforward effect of the torque ring will be.

P274

Model tracking reverse proportional

control

Range

Default

value

Unit Usage

0~1000 100 % P

Instructions are the same as P273.

P277

Model tracking velocity

compensation feedforward

Range

Default

value

Unit Usage

0~1000 100 % P

Model to trace the speed feedforward compensation, the value, the greater the speed loop

feedforward action, the greater the too much may lead to noise.

Modes 1 to 3 are valid.

Loading...

Loading...