7 - 10 VM600 MPS hardware manual (standard version) MAMPS-HW/E

Edition 17 - February 2018

Position measurement

PROCESSING MODES AND APPLICATIONS

7.6 Position measurement

(1) Description

The relative position of a shaft can be measured by placing a proximity probe on the bearing.

This type of measurement is particularly applicable to fluid-film thrust bearings where it is

necessary to measure the axial motion of the shaft relative to the bearing.

The following front-end components are the most commonly used:

• TQxxx proximity transducer + IQSxxx signal conditioner

• TQxxx proximity transducer + IQSxxx signal conditioner + (Intrinsically safe) GSVxxx

power supply and safety barrier (applications).

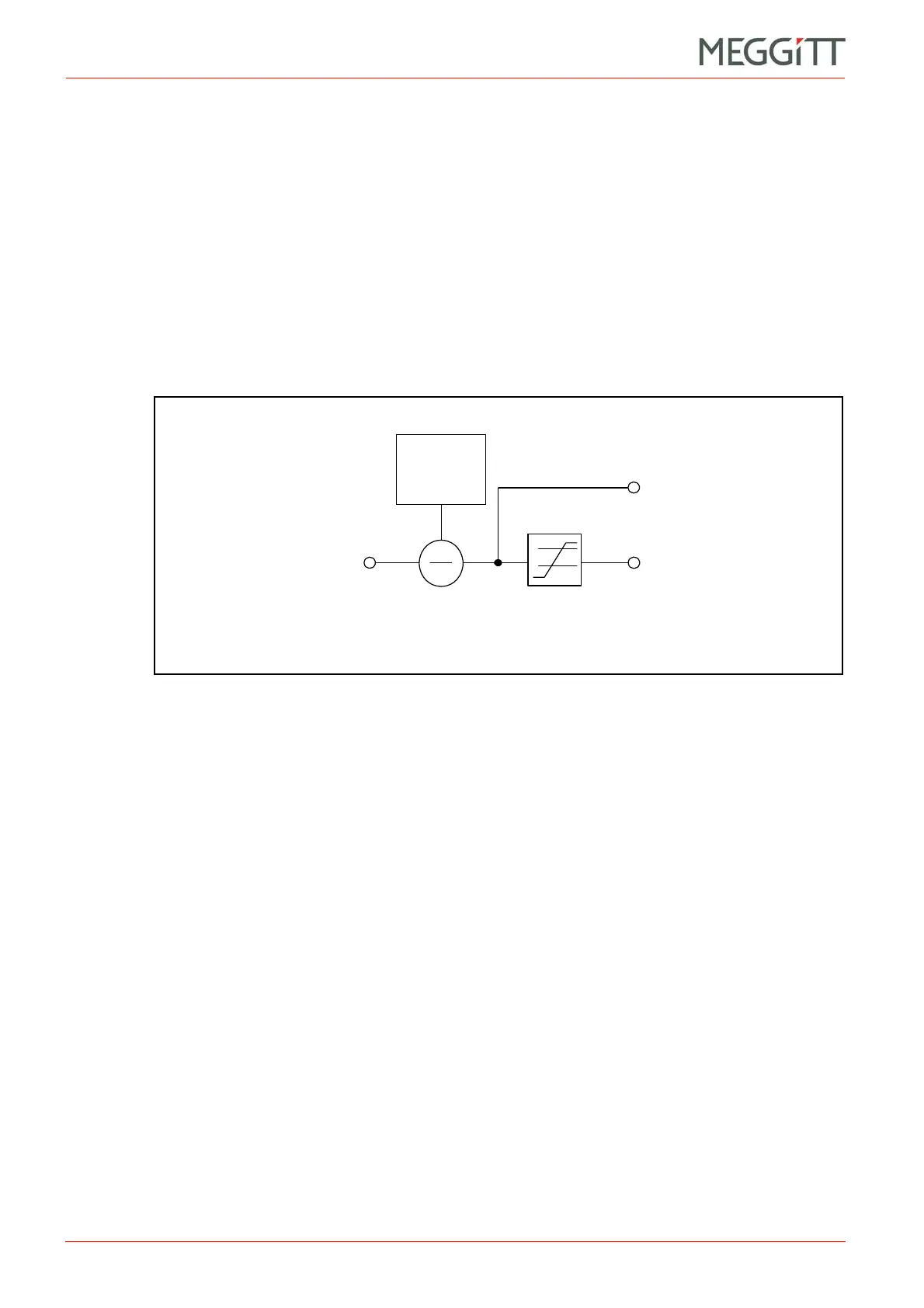

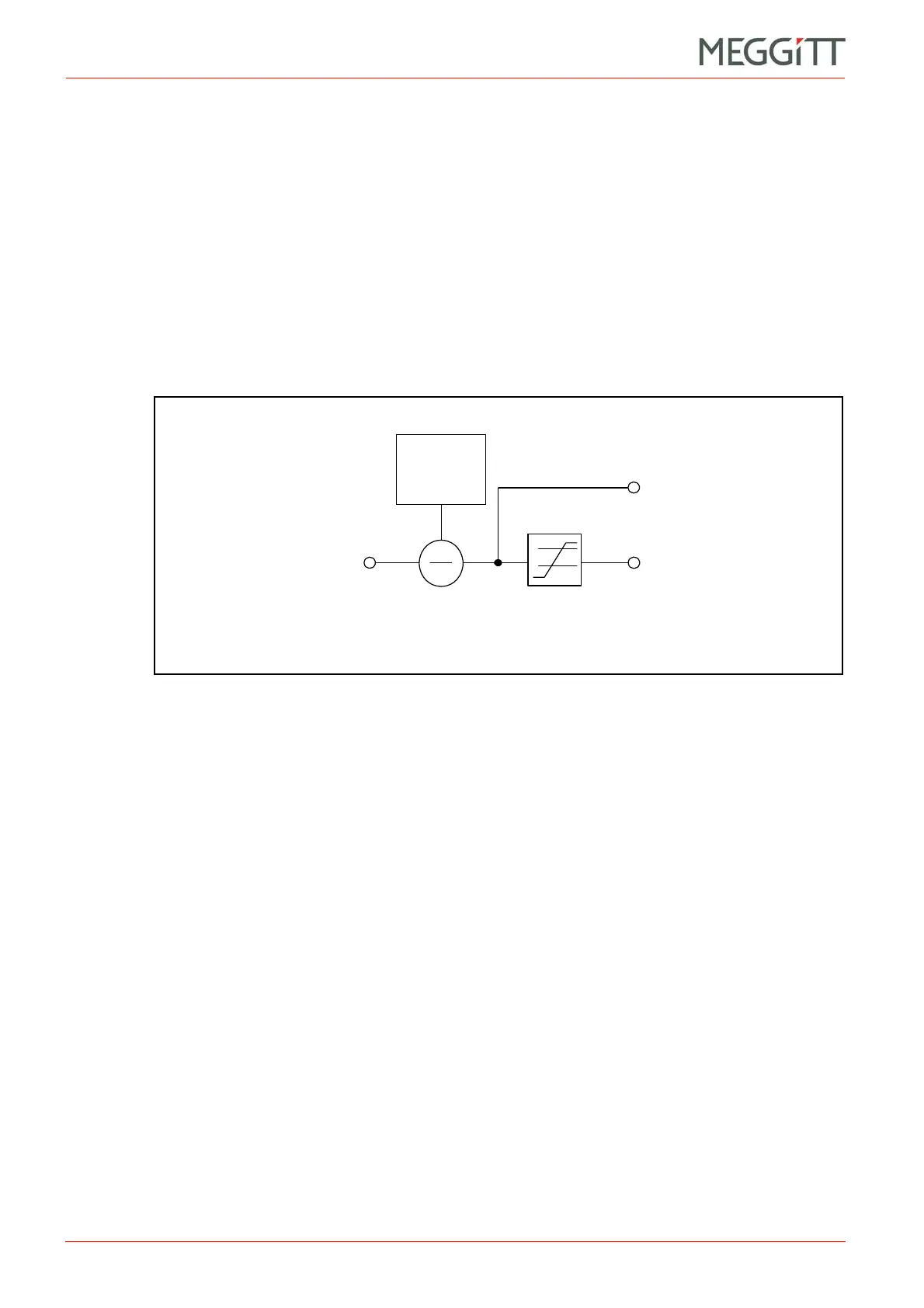

(2) Block diagram

With a proximity probe connected to the MPS, the position processing function calculates the

position of the target relative to a reference point.

The initial target position (gap) must be stored (or configured). This will be used as a

reference position for measurement purposes. This value ( X

initial

) depends on the physical

probe placement, and must be subtracted from the measured value ( X

in

) in order to give

the target position relative to the reference position:

X

out

= X

in

X

initial

7.7 S

max

measurement

(1) Description

S

max

is a vibration measurement used in machinery monitoring systems, defined in

ISO 7919-1 as the maximum vibratory displacement in the plane of measurement.

S

max

monitoring is a special case of shaft relative vibration monitoring that measures the

radial motion of the shaft. Like shaft relative vibration, it is typically measured using two

proximity transducers (X and Y) mounted on the machine bearing at approximately 90° to

each other (see Figure 7-8).

In general, the two proximity transducer (X and Y) values are added vectorially to provide the

S

max

(maximum displacement) value as defined in ISO 7919-1. However, there are different

methods of calculating S

max

, defined as methods A, B and C in ISO 7919-1 Annex B.

Figure 7-7: Block diagram showing position processing

Position value

( X

out

)

Alarms

Position input

( X

in

)

Initial gap

(X

initial

)

Loading...

Loading...