Chapter 4 Helpful Tips

103

4.2 Length Correction [DIST.COMP.]

When cutting long data, discrepancies in the cut length may arise due to the sheet thickness.

Differences in grit roller diameter may also cause discrepancies in feed rate between the left and right sides

of the sheet.

Such discrepancies can be corrected using the length correction function.

Up to eight length correction types (No. 1 to No. 8) can be saved.

l

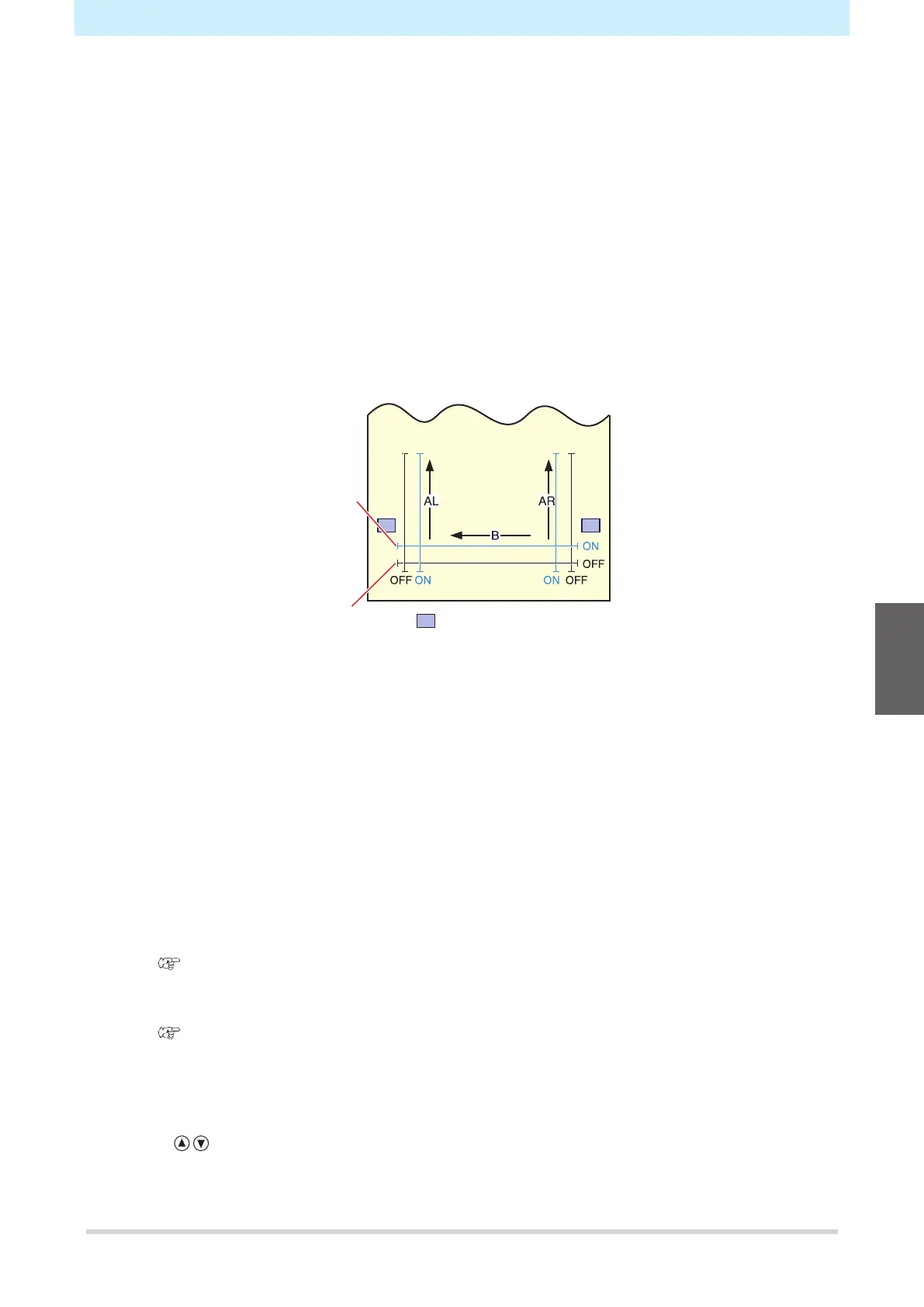

Calculating the correction value

Correction value = (Measured length of OFF line) - (Entered standard length)

Example:

• Measured length of OFF line: 999.0 mm

• Entered standard length: 1,000 mm

• 999.0 - 1,000 = -1.0 mm / (correction value)

Corrected

line

Reference

line

: Pinch roller

Settings:

• Standard value

A direction: 500, 1000, 1500, 2000, 2500 (mm)

B direction (CG-60AR): 200, 400, 600 (mm)

B direction (CG-100AR): 200, 400, 600, 800, 1000 (mm)

B direction (CG-130AR): 200, 400, 600, 800, 1000, 1200 (mm)

• Correction value

A direction: ± 5 % of standard length (0.1 mm steps)

B direction: ± 5 % of standard length (0.1 mm steps)

• Plotting offset: 0 to 300 mm

l

Setting procedure

1

Attach a pen.

• "Using a Pen"(P. 63)

2

Load a sheet.

• "Loading a Sheet"(P. 44)

• Load the sheet on which the length correction adjustment pattern is to be printed.

3

Press the [FUNCTION] key in local mode.

4

Use to select [DIST.COMP.], then press the [ENTER/HOLD] key.

• The correction values saved for No. 1 AR (longitudinal direction right-hand side), AL (longitudinal

direction left-hand side), and B (lateral direction) are displayed.

4

Loading...

Loading...