4 - 11

Chapter 4 Installation, Wiring and Maintenance of the Produc

[1] Precautions for wiring

(1) Use separate cables for connecting to the QD77MS and for the power cable

that create surge and inductance.

(2) The cable for connecting QD77MS can be placed in the duct or secured in

place by clamps. If the cable is not placed in the duct or secured by clamps,

unevenness or movement of the cable or careless pulling on it could result

in damage to the unit or cable or defective cable connections could cause

mis-operation of the unit.

(3) If a duct is being used and cables to connect to QD77MS are separated

from the power line duct, use metal piping.

Ground the pipes securely after metal piping.

(4) Use the twisted pair shielded cable (wire size 0.3 mm

2

or more). The

shielded must be grounded on the QD77MS side. (The following figure

shows a wiring example.)

(5) Use separate shielded cables of the forced stop input signal (EMI,

EMI.COM), limit signal (FLS RLS DOG STOP), external command

signal/switching signal (DI, COM), and manual pulse generator/incremental

synchronous encoder input signal (HAH, HAL, HBH, HBL, HA, HB, 5V, SG)

for connecting to the QD77MS. They can cause electrical interference,

surges and inductance that can lead to mis-operation.

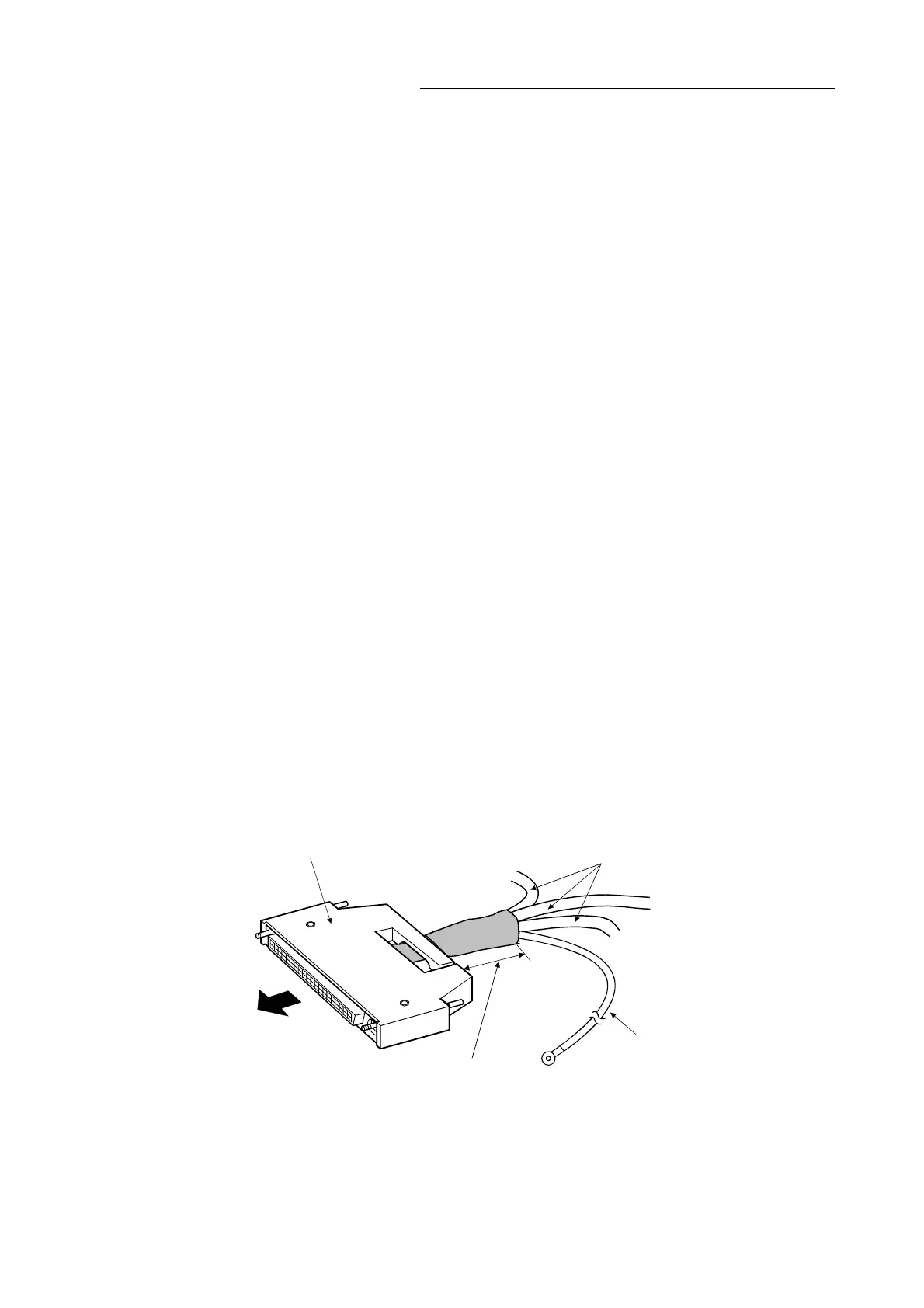

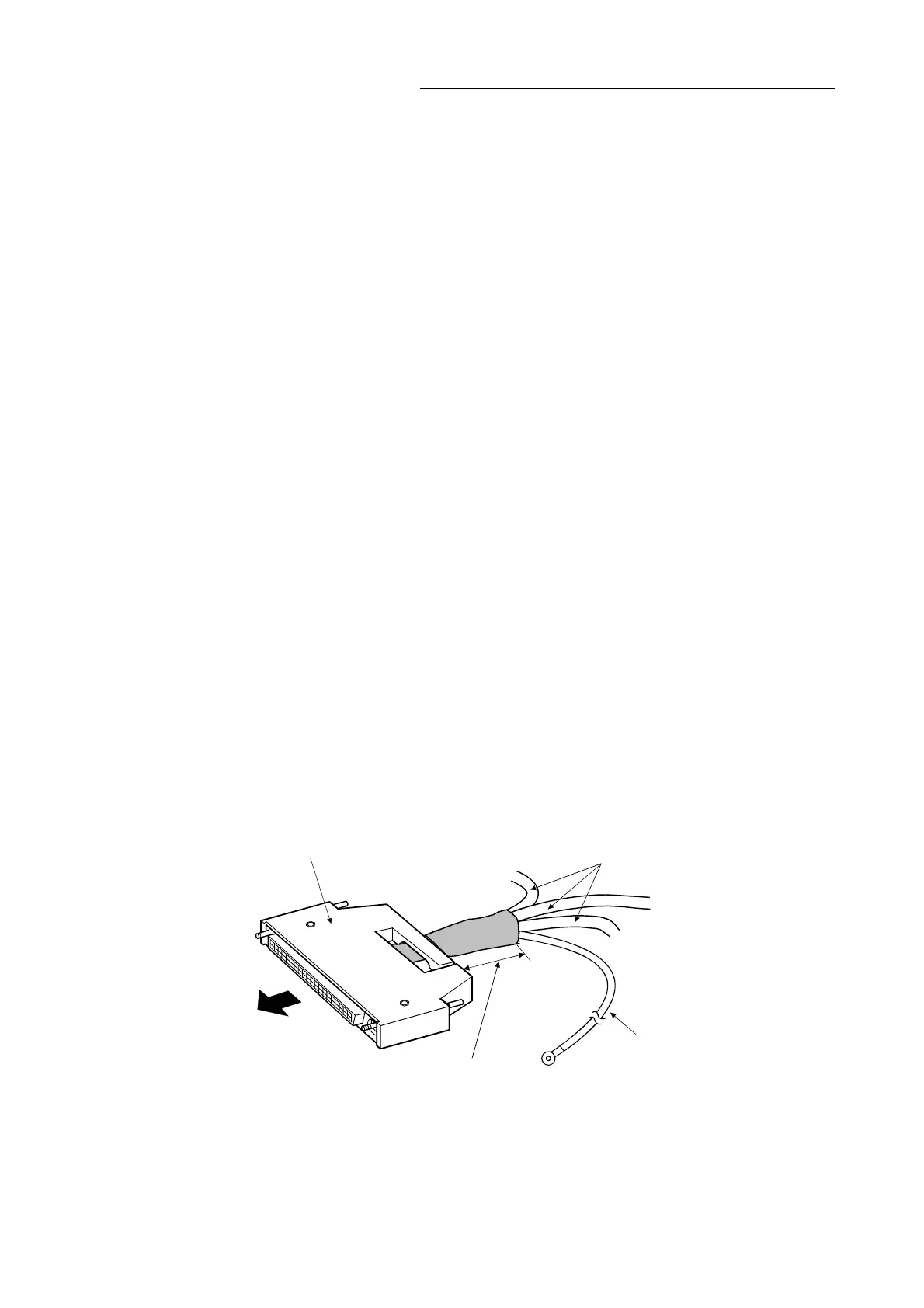

[Wiring example of shielded cable]

The following shows a wiring example for noise reduction in the case when the

connector (A6CON1) is used.

To QD77MS

Connector

(A6CON1)

Shielded

cable

The length between the connector and the

shielded cables should be the shortest possible.

Use the shortest possible length to

ground the 2mm

2

or more FG wire.

(The shield must be grounded on

the QD77MS side.)

For forced stop

input signal

For limit signal,

etc.

For manual pulse

generator signal

Loading...

Loading...