5 - 38

Chapter 5 Data Used for Positioning Control

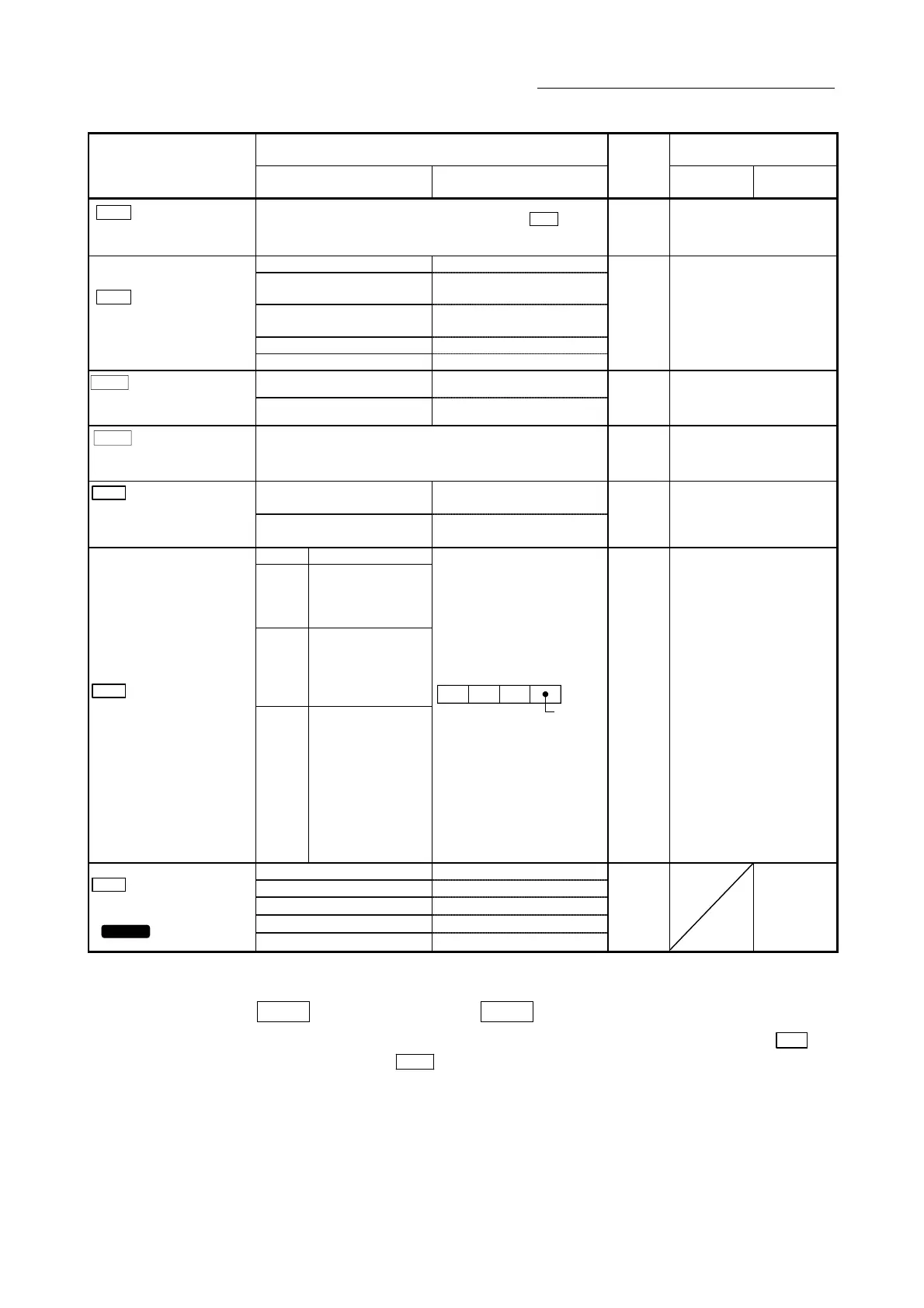

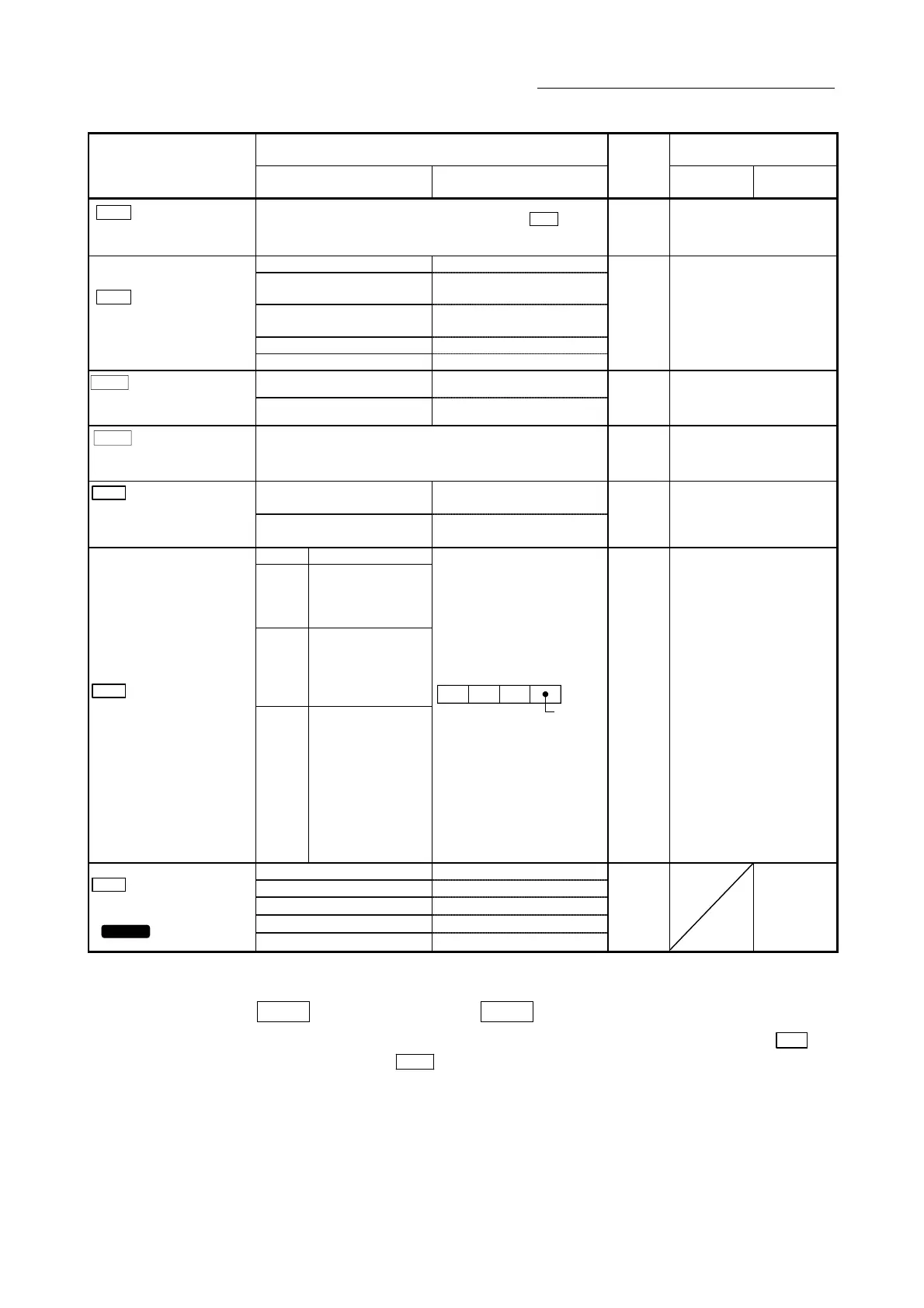

Setting value, setting range

Setting value buffer memory

address

Item

Value set with GX Works2

Value set with sequence

program

Default

value

QD77MS2

QD77MS4

QD77MS16

Pr.41

Allowable circular

interpolation error width

The setting value range differs depending on the "

Pr.1

Unit

setting".

100

60+150n

61+150n

0: External positioning start 0

1: External speed change

request

1

2: Speed-position, position-

speed switching request

2

3: Skip request 3

Pr.42

External command function

selection

4: High speed input request 4

0 62+150n

0: Invalid 0

Pr.83

Speed control 10 x multiplier

setting for degree axis

1: Valid 1

0 63+150n

Pr.84

Restart allowable range

when servo OFF to ON

0, 1 to 327680 [PLS]

0: restart not allowed

0

64+150n

65+150n

0: Differential output type 0

Pr.89

Manual pulse generator/

Incremental synchronous

encoder input type selection

1: Voltage output/open collector

type

1

1 67

b0 to b3 Not used

b4 to b7

Torque initial value

selection

0: Command torque

1: Feedback torque

b8 to

b11

Speed initial value

selection

0: Command speed

1: Feedback speed

2: Automatic selection

Pr.90

Operation setting for speed-

torque control mode

b12 to

b15

Condition selection at

mode switching

0: Switching

conditions valid (for

switching control

mode)

1: Zero speed ON

condition invalid

(for switching

control mode)

b15 to b12b11 to b8 b7 to b4 b3 to b0

Always "0" is

set to the part

not used.

0000H 68+150n

0: Not used 0

1: DI1 1

2: DI2 2

3: DI3 3

Pr.95

External command signal

selection

QD77MS16

4: DI4 4

0

69+150n

n: Axis No.-1

Pr.25

Acceleration time 1 to

Pr.27

Acceleration time 3

These parameters set the time for the speed to increase from zero to the " Pr.8

Speed limit value" (" Pr.31 JOG speed limit value" at JOG operation control) during a

positioning operation.

Loading...

Loading...