9 - 121

Chapter 9 Major Positioning Control

(3) An axis error "Outside new current value range (error code: 514)" will occur

and the operation cannot start if "degree" is set in "

Pr.1

Unit setting" and the

value set in "

Da.6

Positioning address/movement amount (0 to 359.99999

[degree])" is outside the setting range.

(4) If the value set in "

Da.6

Positioning address/movement amount" is outside

the software stroke limit (

Pr.12

,

Pr.13

) setting range, an error "Software

stroke limit +,

-

(error code: 507 or 508)" will occur at the positioning start, and

the operation will not start.

(5) An error (error code: 507 or 508) will occur if the new current value is outside

the software stroke limit range.

(6) The new current value using the positioning data (No.1 to 600) cannot be

changed, if "0: Positioning control is not executed" is set in "

Pr.55

Operation

setting for incompletion of OPR" and "OPR request flag" ON. A warning

"Operation setting for incompletion of OPR at positioning start error" (error

code: 547) will occur.

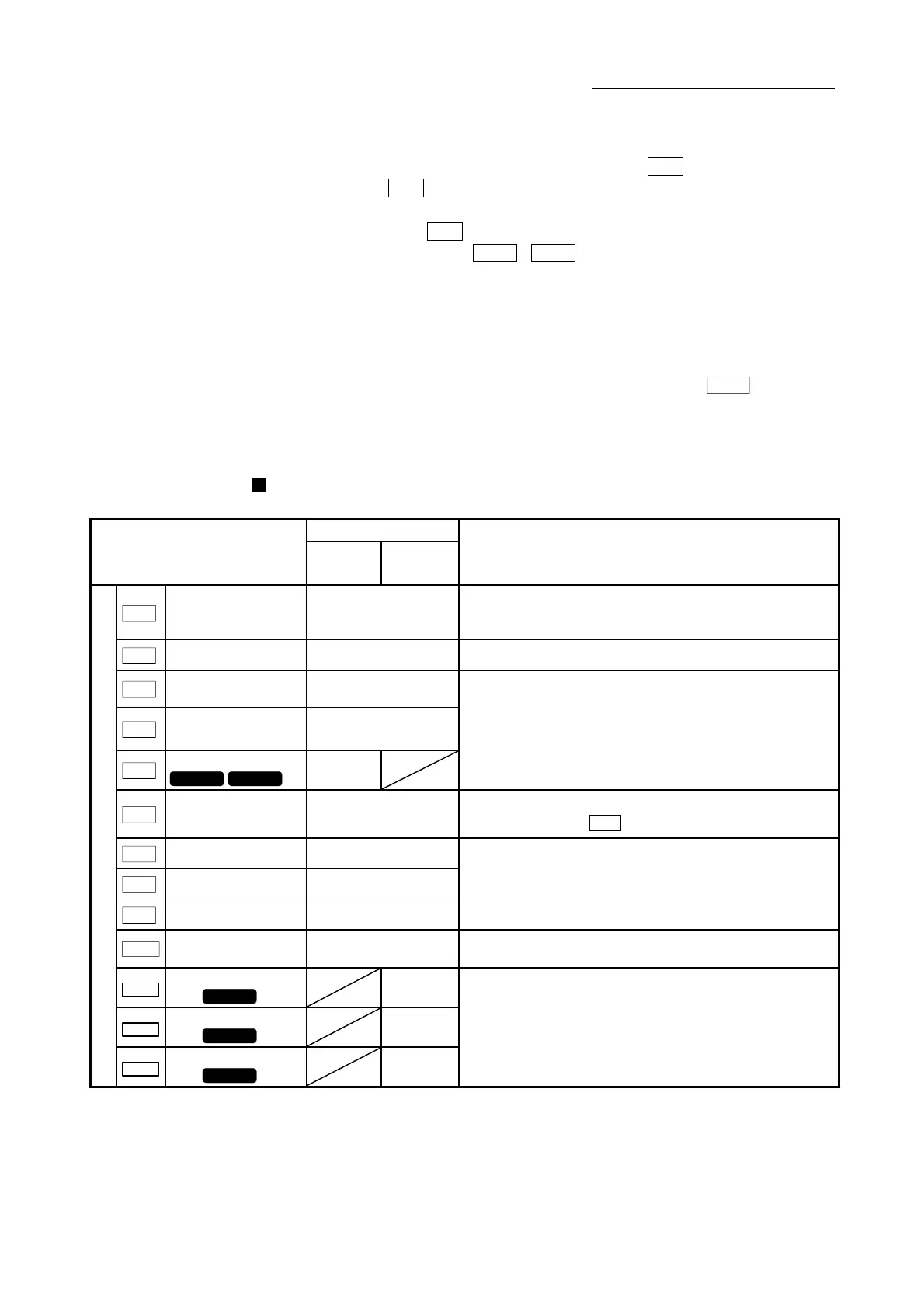

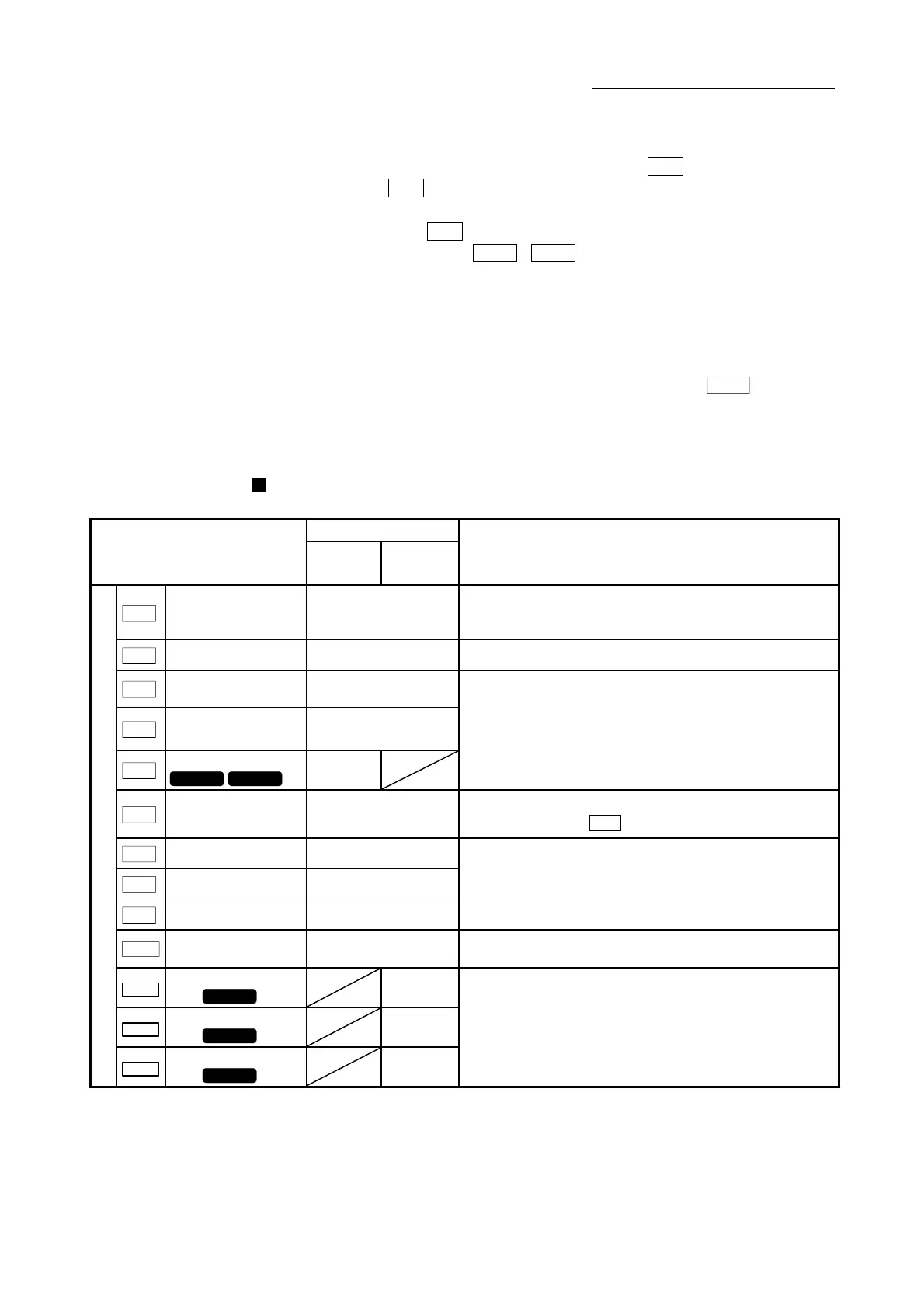

Positioning data setting examples

[When " current value changing" is set in the positioning data No. 1 of axis 1]

Setting example

Setting item

QD77MS2

QD77MS4

QD77MS16

Setting details

Da.1

Operation pattern Positioning complete

Set "Positioning complete" assuming that the next positioning

data will be executed. ("Continuous path control" cannot be

set by current value change.)

Da.2

Control system Current value changing Set the current value changing.

Da.3

Acceleration time No. –

Da.4

Deceleration time No. –

Da.5

xis to be interpolated

QD77MS2 QD77MS4

–

Setting not required (Setting value is ignored.)

Da.6

Positioning address/

movement amount

10000.0

μ

m

Set the address to which address change is desired.

(Assuming that the "

Pr.1

Unit setting " is set to "mm".)

Da.7

Arc address –

Da.8

Command speed –

Da.9

Dwell time –

Setting not required (Setting value is ignored.)

Da.10

M code 10

Set this when other sub operation commands are issued in

combination with the No.1 positioning data.

Da.20

xis to be interpolated

No.1

QD77MS16

–

Da.21

xis to be interpolated

No.2

QD77MS16

–

Axis 1 Positioning data No. 1

Da.22

xis to be interpolated

No.3

QD77MS16

–

Setting not required (setting value is ignored).

(Note): Refer to Section 5.3 "List of positioning data" for information on the setting details.

Loading...

Loading...