167

Programming Console Operations Section 4-2

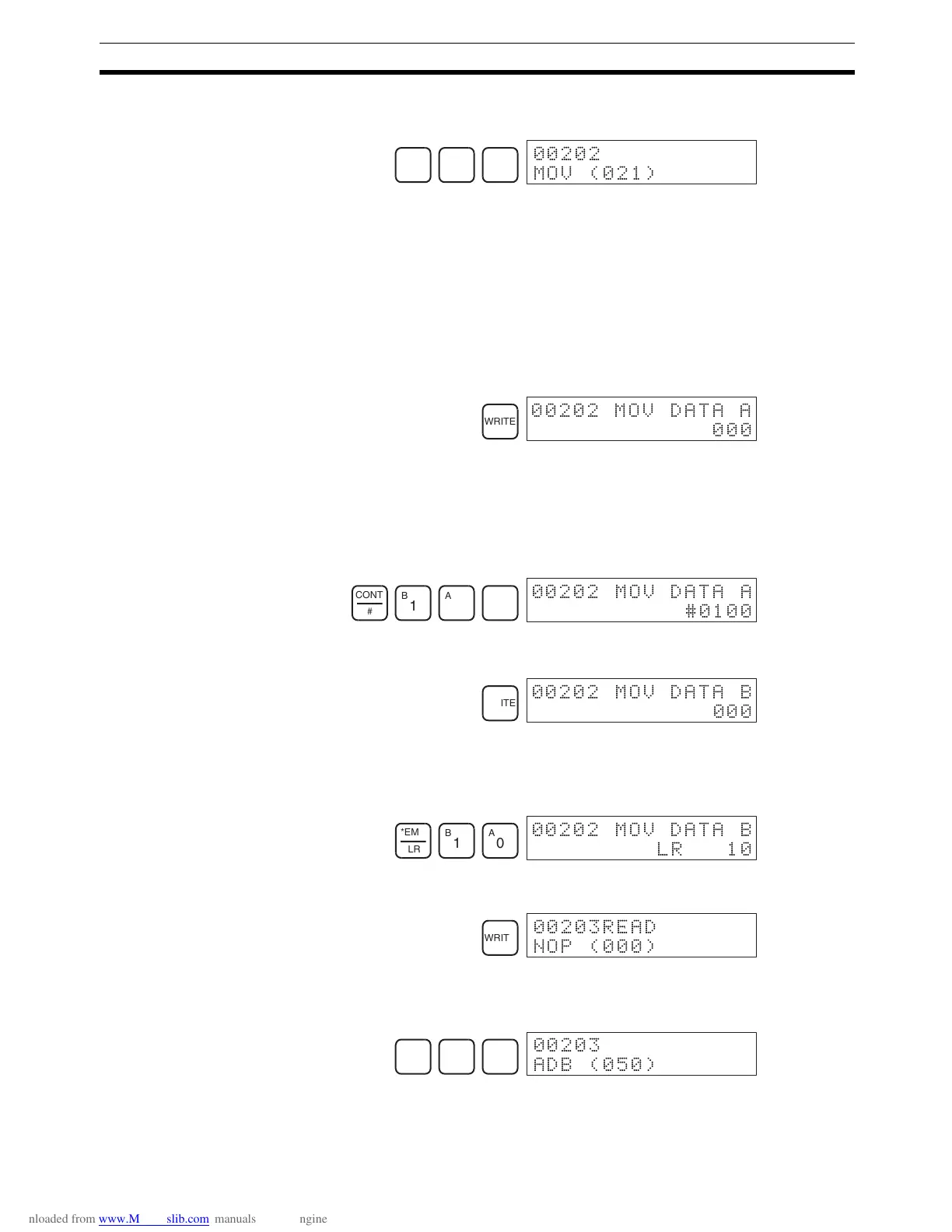

8. Input the third instruction and its operands. First input the instruction by

pressing the FUN Key and then the function code (21 in this case).

To input the differentiated version of an instruction, press the NOT Key af-

ter the function code (FUN 2 1 NOT). The “@” symbol will be displayed

next to differentiated instructions. Press the NOT Key again to change back

the instruction back to a non-differentiated instruction. The “@” symbol will

disappear.

To change an instruction after it has been entered, simply scroll through

the program until the desired instruction is displayed and press the NOT

Key. The “@” symbol should be displayed next to the instruction.

9. Press the WRITE Key to write the instruction to Program Memory. The in-

put display for the first operand will be displayed.

• Writing Hexadecimal, BCD Constant

10. Input the first operand.

The operands of MOV (21) are normally word addresses, but a constant

can be input by pressing the CONT/# Key first. When the CONT/# Key is

pressed, the display will change to “#0000,” indicating that a constant can

be entered.

Press the WRITE Key to write the instruction to Program Memory. The in-

put display for the second operand will appear.

Note The operands of MOV(21) can be word addresses, so the CONT/#

Key must be pressed to input a constant.

• Writing a Word Address

11. Input the second operand.

Press the WRITE Key to write the instruction to Program Memory. The next

program address will be displayed.

Note When the default display value is “000”, a word address can be input

immediately without pressing the Shift and CH/# Keys.

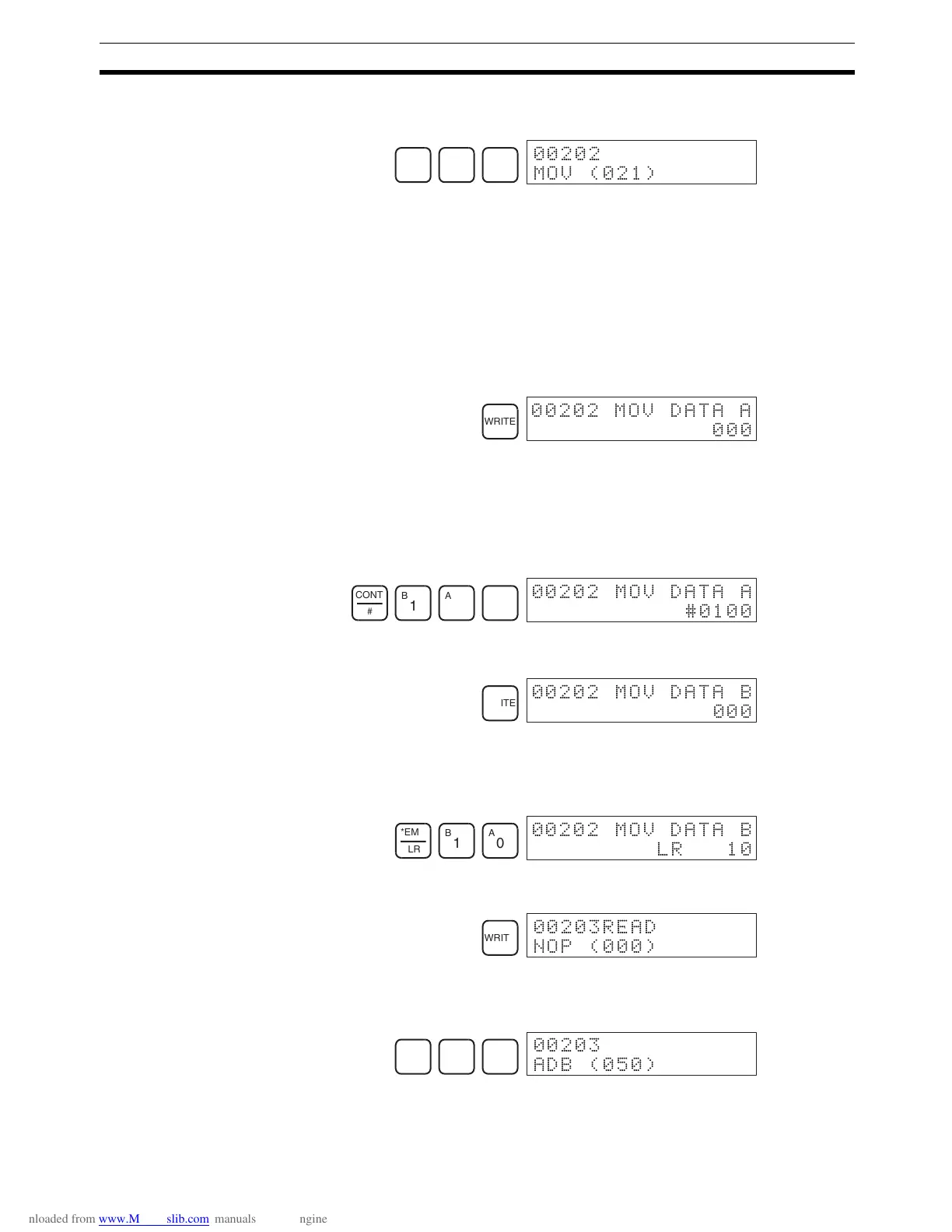

12. Input the next instruction.

Press the WRITE Key to write the instruction to Program Memory.

FUN

C

2

B

1

00202

MOV (021)

WRITE

00202 MOV DATA A

000

CONT

#

B

1

A

0

A

0

00202 MOV DATA A

#0100

WRITE

00202 MOV DATA B

000

*EM

LR

B

1

A

0

00202 MOV DATA B

LR 10

WRITE

00203READ

NOP (000)

FUN

F

5

A

0

!

),* #

Loading...

Loading...