198

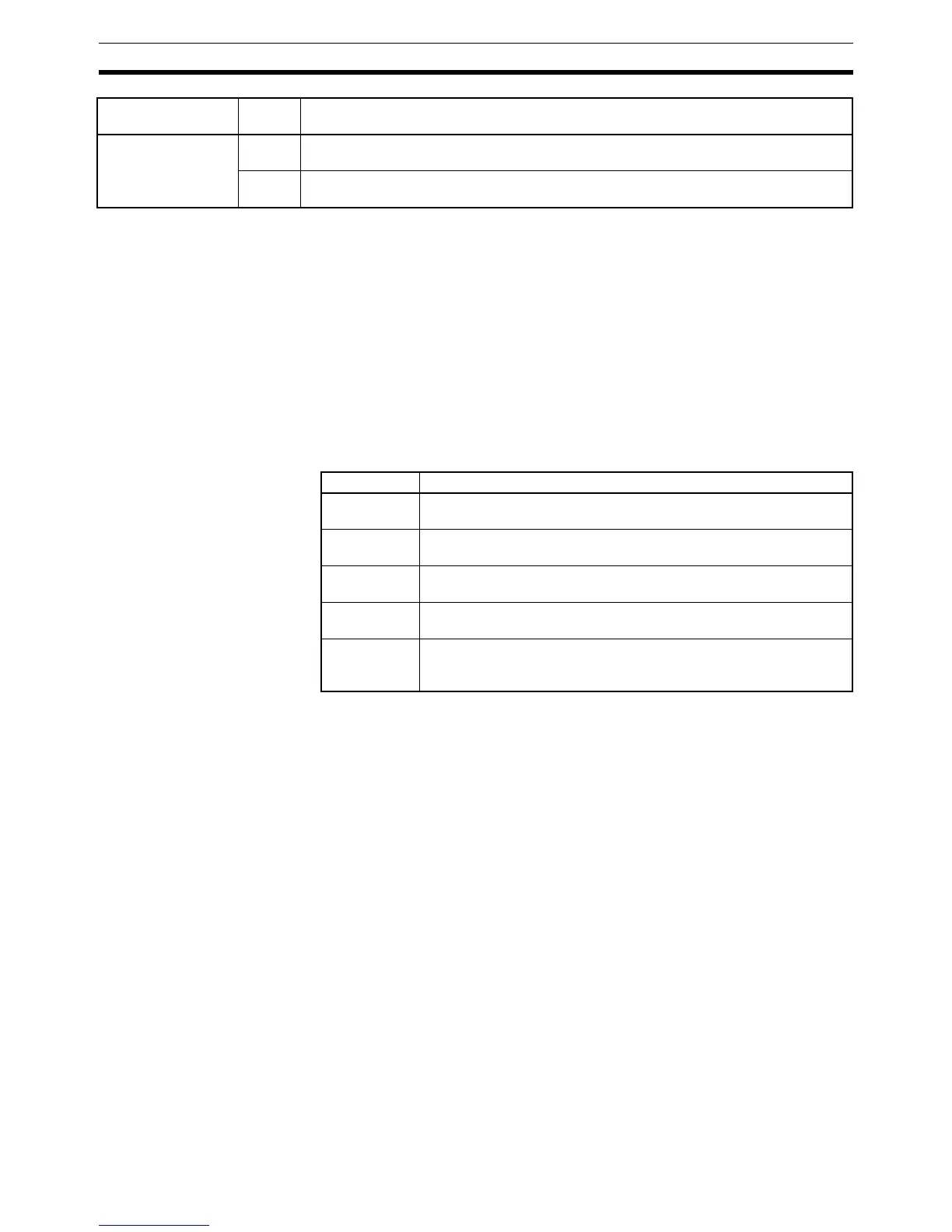

Programming Console Operation Errors Section 5-3

5-2-5 Communications Errors

The COMM indicator will be turned OFF and AR 0812 will be turned ON if an

error occurs in communications through the peripheral port or AR 0804 will be

turned ON if an error occurs in communications through the RS-232C port.

Check the connecting cables and restart.

There are no error messages or error codes generated by this error and the

ERR/ALM indicator is not affected.

5-3 Programming Console Operation Errors

The following error messages may appear when performing operations on the

Programming Console. Correct the error as indicated and continue operation.

Note Refer to the relevant Support Software Operation Manual for details on errors

that may appear when operating the SSS or SYSMAC-CPT Support Soft-

ware.

5-4 Programming Errors

These errors in program syntax will be detected when the program is checked

using the Program Check operation.

Three levels of program checking are available. The desired level must be

designated to indicate the type of errors that are to be detected. The following

table provides the error types, displays, and explanations of all syntax errors.

SYS FAIL FALS**

(** is 01 to 99 or 9F.)

01 to 99 A FALS(07) instruction has been executed in the program. Check the FALS number to

determine the conditions that caused execution, correct the cause, and clear the error.

9F The cycle time has exceeded the Maximum (Watch) Cycle Time setting (DM 6618).

Check the cycle time and adjust the Maximum Cycle Time setting if necessary.

Message FALS

No.

Meaning and appropriate response

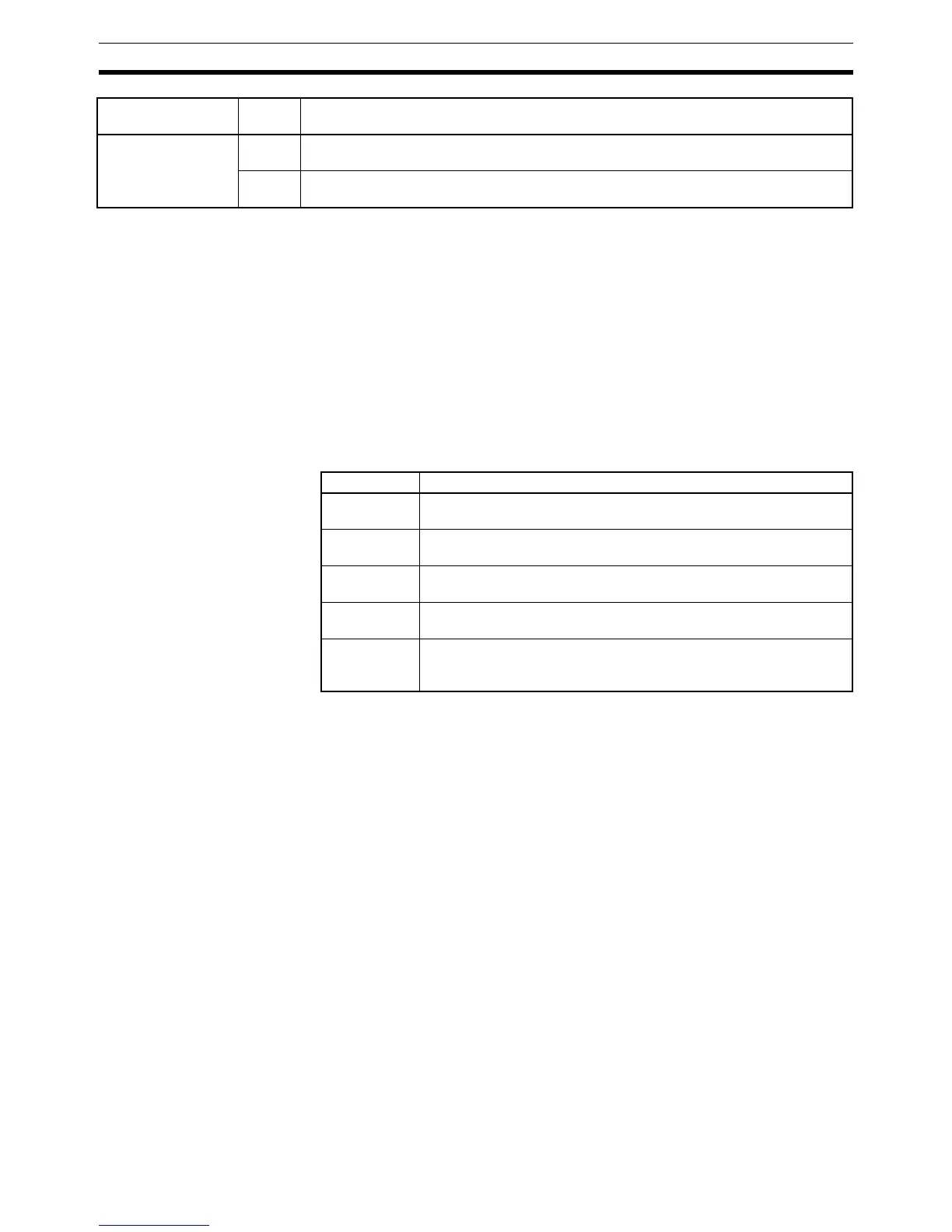

Message Meaning and appropriate response

REPL ROM An attempt was made to write to write-protected memory. Set bits 00

to 03 of DM 6602 to “0.”

PROG OVER The instruction at the last address in memory is not NOP(00). Erase

all unnecessary instructions after END(01).

ADDR OVER An address was set that is larger than the highest memory address

in Program Memory. Input a smaller address.

SETDATA

ERR

FALS 00 has been input, and “00” cannot be input. Reinput the data.

I/O NO. ERR A data area address has been designated that exceeds the limit of

the data area, e.g., an address is too large. Confirm the requirements

for the instruction and re-enter the address.

Loading...

Loading...