60-1

Powerscreen® XA750S

7

5

2

2

1

40

EN

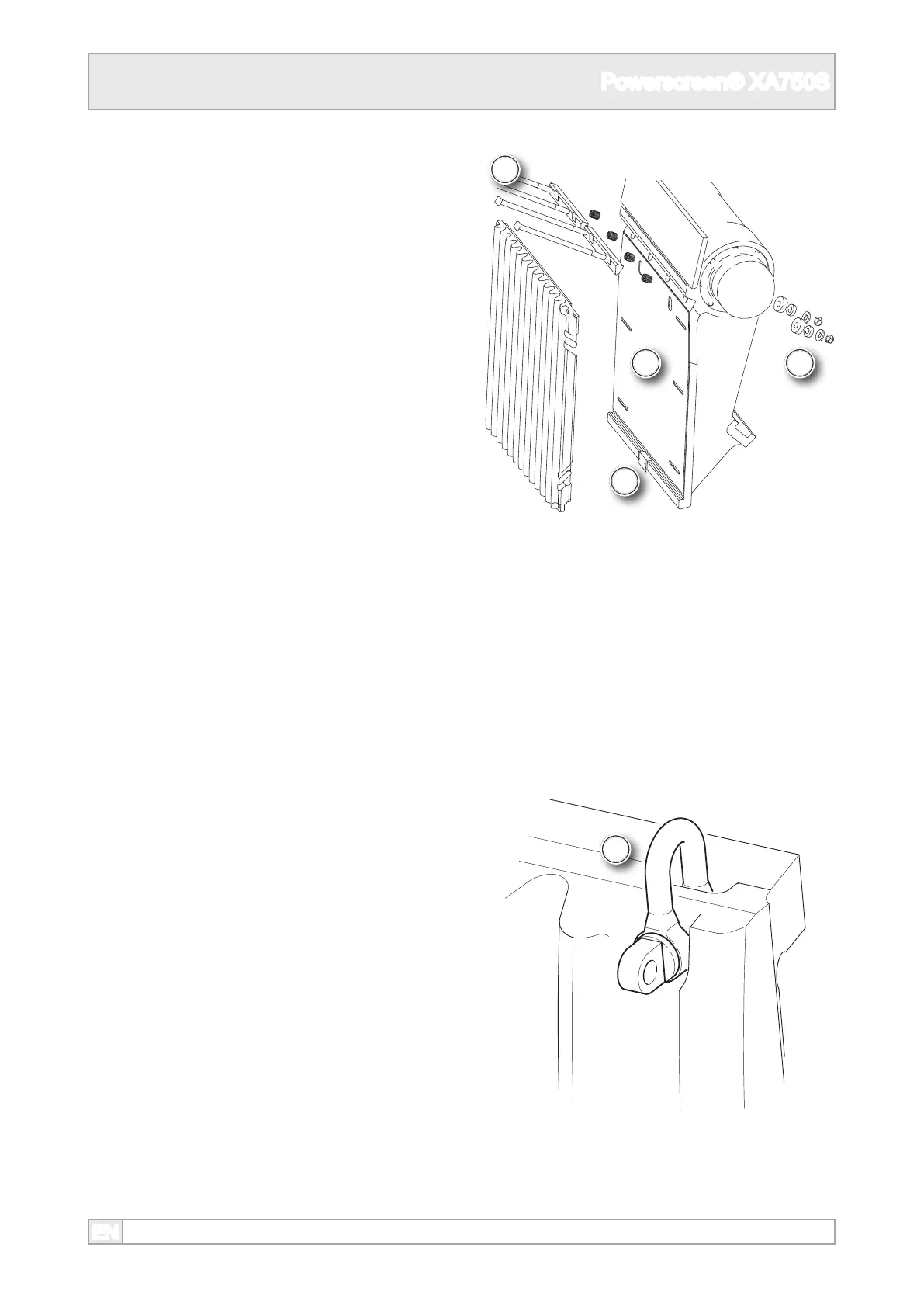

Fitting the Moving Jaw

1. Inspect the backing plate and remove any burrs

as necessary to create a smooth surface or

renew the plate.

2. Renew any wedge locking nuts and bolts if they

are damaged or bolt is bent.

3. The jaw can be turned when half worn, the lower

worn part being re-tted at the top.

4. When turning over and re-using a jaw, clean the

back face and remove any burrs

5. Check the centre jaw location for wear. The

nominal width of the location lug on the jaw

holder when new is 73 to 74mm (2.9in) and

if the wear is more than 5mm (0.2in), the

sides will require building up with hard weld

and shaping to make sure it locates the jaw

centrally.

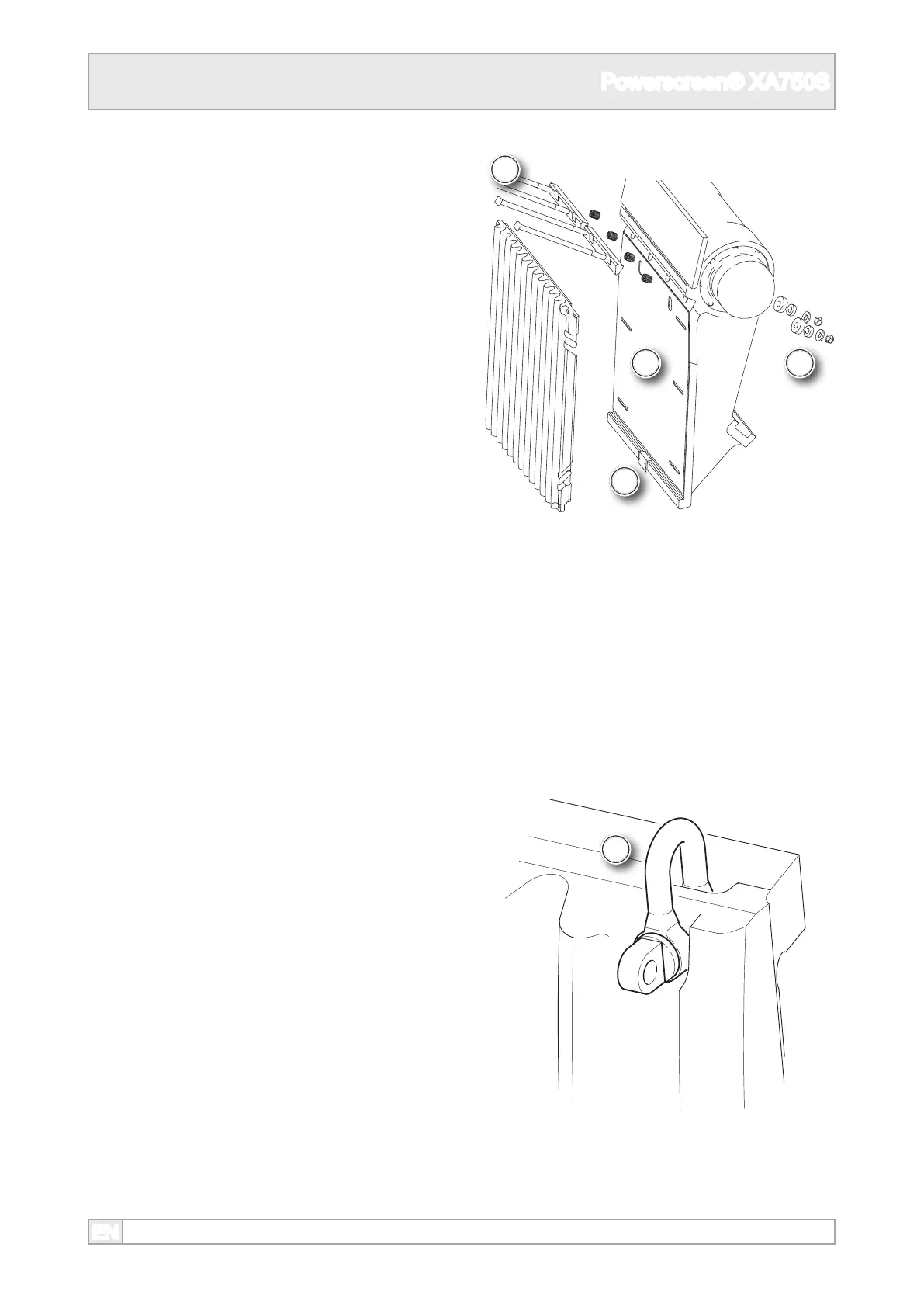

7. Fit suitable lifting shackles to the upper corners

of the jaw.

8. Fix suitable lifting equipment to the shackles

and support the weight using suitable lifting

equipment.

6. If welding is required, refer to any welding

notices on plant and in servicing safety and

precautions.

Loading...

Loading...