1-2 Description – Overview

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

Overview

Preferred Instruments' FlexFit 110 is a ame safeguard and linkageless, parallel positioning combustion control system. It is the

next innovative leap to offer the benets of parallel positioning without the high cost or effort of previous parallel positioning upgrades.

Draft control and Oxygen trim options are provided for additional combustion efciency and consistent fuel/air ratios.

The FlexFit replaces existing ame safeguard systems, or it can be used in a new installation. It is designed for any single burner,

one or two fuels, retube or watertube, steam or hot water boiler. It is offered with a complete package of eld devices, or it can be

used with compatible existing equipment. Commissioning is done using the FlexFit's LCD display.

The FlexFit 110 is UL/CSA 60730-1, 2-5 recognized, having both fuel/air ratio control and ame safeguard capabilities. Along with

all other requirements, NFPA 85 compliance is met by having total separation of the fuel/air ratio control and ame safeguard hardware.

The Burner Management System (BMS) (FlexFit-BMS) governs the step-by-step starting sequence for the red equipment.

At the release to modulate state, control is turned over to the combustion control system until the operator elects to shut down the

system, there is no longer a call for heat, or an abnormality results in a BMS-directed shutdown of the equipment. The BMS also

provides ame supervision, system status indication, system and self-diagnostics, and troubleshooting features.

The Combustion Control System (CCS) (FlexFit-CC) is responsible for burner fuel/air ratio control. During the startup and

shutdown sequences, fuel, air, FGR, draft, O

2

trim, or other auxiliary control elements are directed to specic positions by the BMS.

In the modulate state, their positions are governed by the CCS. The FlexFit uses a parallel positioning control system.

The FlexFit-CC provides three analog inputs for various uses (boiler outlet, draft, remote setpoint, 135-ohm ring rate), oxygen

sensor inputs with optional stack temperature, and two analog outputs with paired feedback analog inputs, typically used for VSD

control. Modbus RS485 communication is provided for SCADA, building automation, etc. Additionally, the FlexFit can accommodate

up to seven control servos depending on application requirements. Examples of typical servo applications include the following:

• Fuel 1 servo

• Fuel 2 servo

• Tandem fuel valves (single servo for linked fuel valves)

• Combustion air FD damper servo

• FGR damper servo

• Atomizing steam control servo

• Outlet damper servo for draft control

Typical 4-20 outputs and inputs include the following:

• FD VSD

• FGR VSD

Features

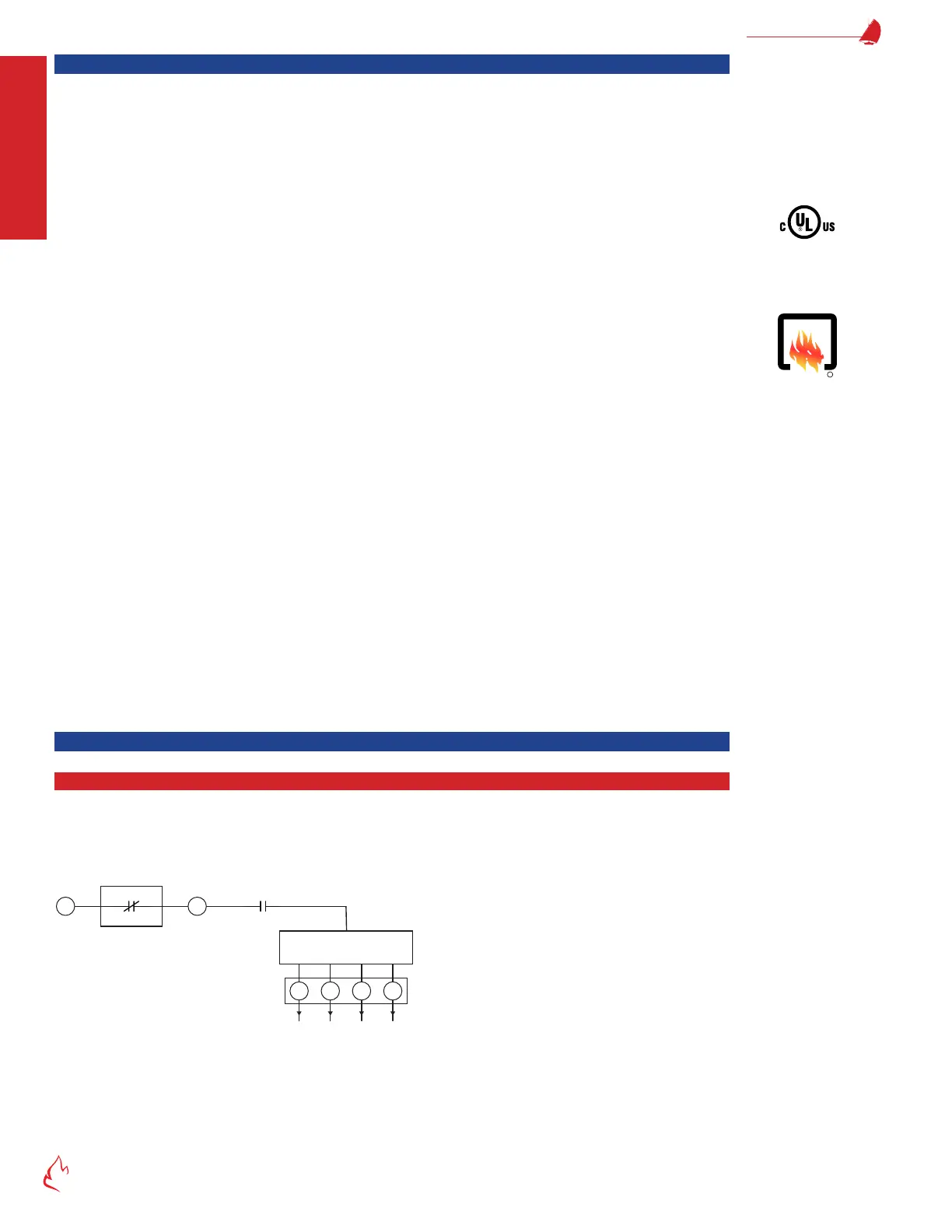

Safety Relay

The safety relay (K1) provides 120 VAC to all ignition source and fuel valve relays. When the safety relay is deenergized, the

120 VAC is removed from the safety power bus. Each safety bus relay output contact is individually monitored, and the safety relay

coil deenergizes if any safety bus relay malfunctions.

Figure 1 – 1 FlexFit 11

3 P

Interlocks

Safety Relay

K1

W 765

Ignition and Fuel Valve

Control Circuit

Ignition Xfmr

Pilot (10 sec TFI)

Pilot (15 sec TFI) (or V2)

Main Fuel Valves (or V1)

0 Safety Relay

XAAF Burner

LISTED

R

Loading...

Loading...