2-24 Installation – Servo Installation

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

II

NN

SS

TT

AA

LL

LL

AA

TT

II

OO

NN

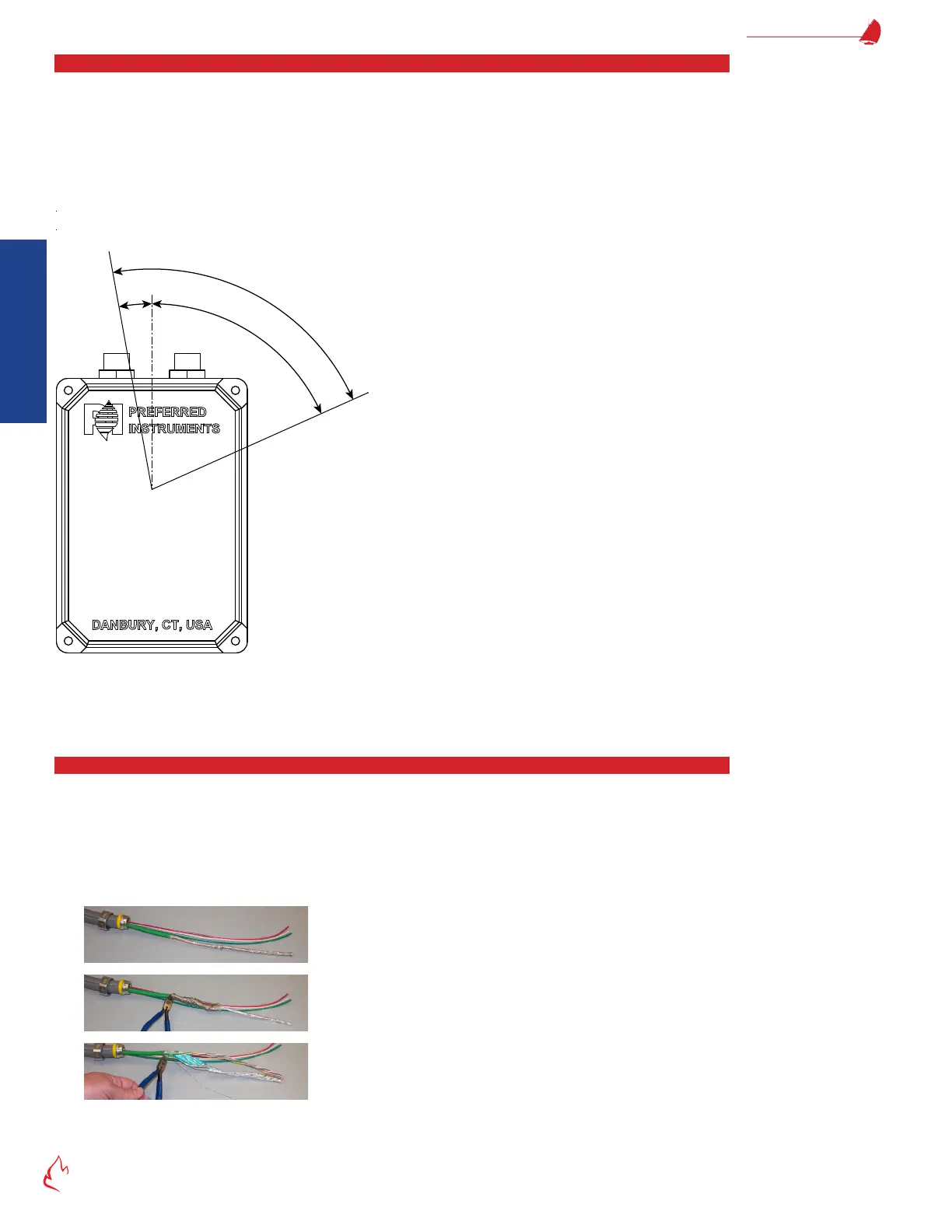

Servo Mechanical Installation

Mechanically connect the servo to the valve or damper such that the shaft will not slip, and the servo does not move under

load. The servo stroke must be between 15 and 180 degrees and cannot stroke inside the forbidden zone. If necessary, rotate the

servo mounting connection 90 or 180 degrees to avoid the forbidden zone. Once the servo installation location and orientation are

nalized, drill and pin the servo shaft coupling to the valve or damper to ensure that alignment does not slip or change. For a list of

common servo couplings and mounting brackets, see the "Parts List" on page A-109.

Figure 2 – 11

Shaft Rotation Forbidden Zone

(Perpendicular to the flat on the shaft)

6

6

°

7

6

°

1

0

°

Servo Forbidden Zone

The servo limit switches and addresses will be congured during the commissioning process. If desired or more convenient,

they may be set at this time. Refer to section "Servo Setup" on page 3-47, if necessary.

Servo Wiring

This section applies to standard servo wiring (P/N: BMU-CABLE-XX). If using the QD1 quick disconnect cables, refer to "QD1

Quick Disconnect Cables" on page 2-26.

Pull one P/N BMU-CABLE-XX and three 16 gage THHN wires through a 1/2" ex conduit with enough slack for servicing. For

daisy chain wiring, use two conduits, with each conduit containing only one P/N BMU-CABLE-XX and three 16 gage THHN wires.

Do not pull two shielded cables through one servo conduit connection.

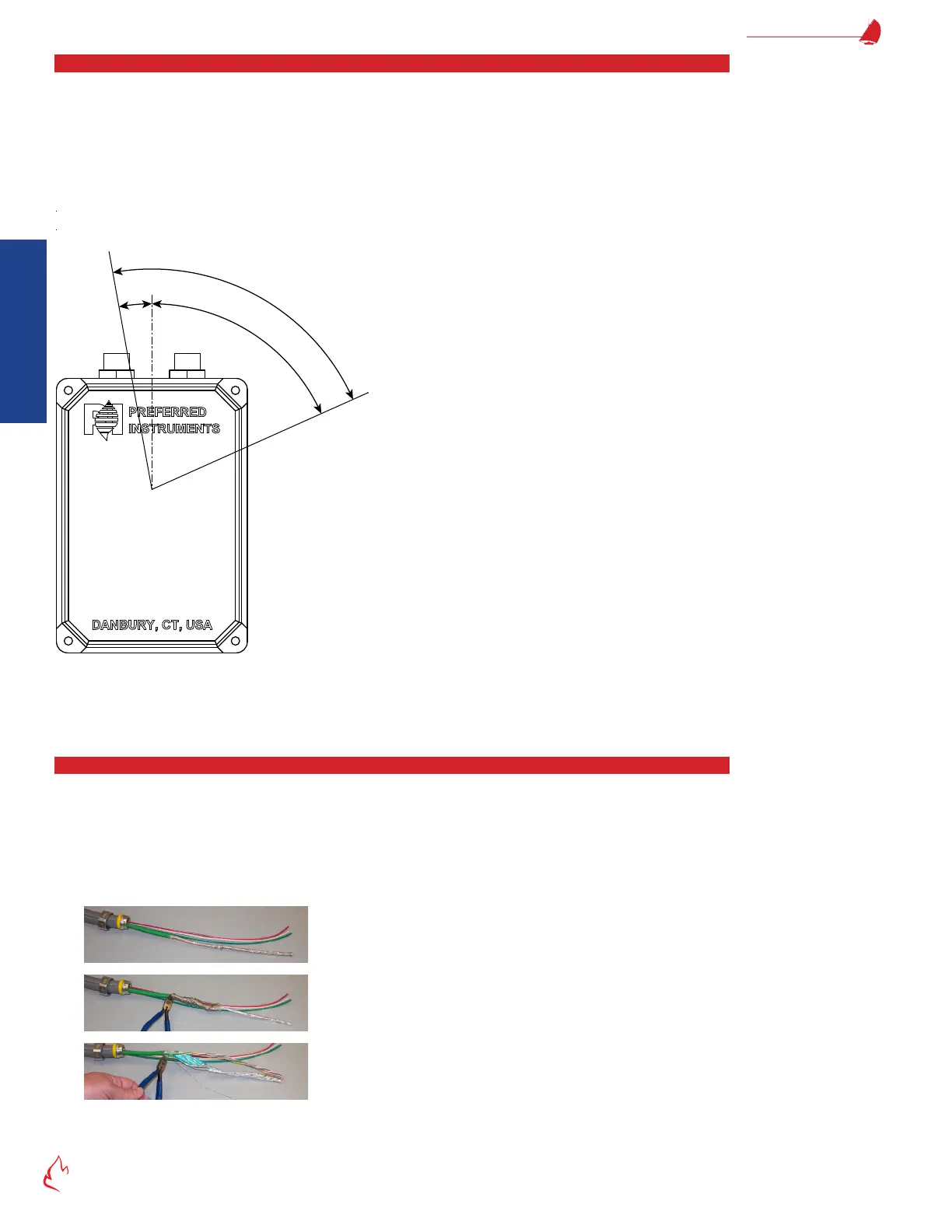

Before pulling the cables into the servo, prepare the cable ends as follows:

Leaving about 11-12" of cable, remove 8" of green cable insulation.

Push back the braided shield and cut it off. Do not cut off the bare drain wire.

Remove the foil shield. Keep the wire pairs twisted together.

Loading...

Loading...