5-90 Troubleshooting – ZP Oxygen Analyzer Troubleshooting

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

TT

RR

OO

UU

BB

LL

EE

SS

HH

OO

OO

TT

II

NN

GG

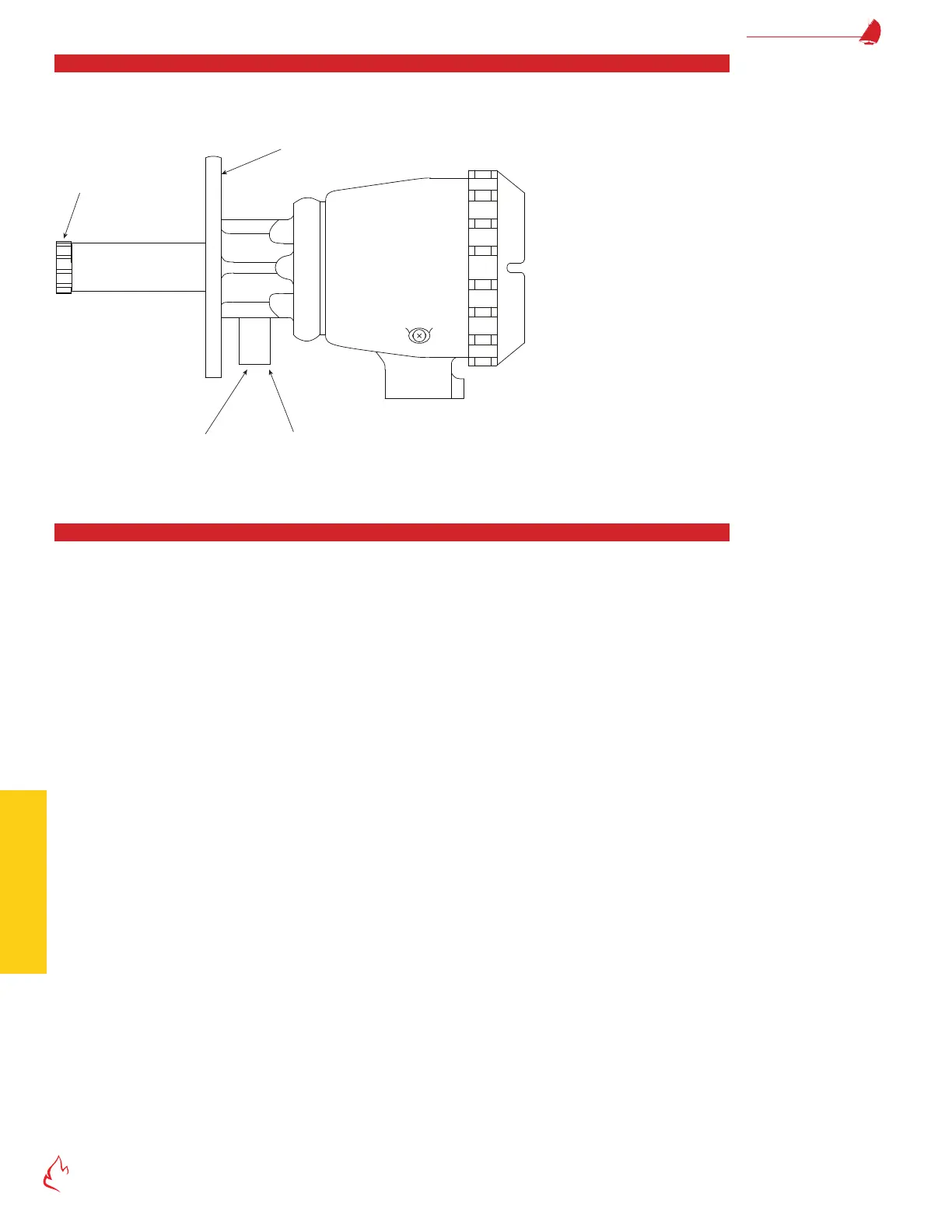

Low Calibration Gas Flow Rate

Disconnect the tubing at the calibration port on the detector. Verify that the gas is owing up to the detector. If the detector

ange is overheated, the elastomer calibration gas check valve may become stuck shut. Use a toothpick or paper clip to gently push

open the check valve.

Figure 5 – 1

Filter

Calibration Port

Viton Seal Inside

Calibration Port Check Valve

Detector Leak Test

If the cell is cracked or broken, ue gas can leak into the reference side of the cell and cause an incorrect reading. If the Viton

seal between the cell tube extension and the detector head is overheated it can leak and cause an incorrect reading. See "Measuring

Principle" on page 2-30, for the principle of operation.

Test for Leaks as follows:

1. Turn off the power and remove the detector from the process. Wait for the detector to cool down. Remove the outer lter

and the inner calibration gas deector washer.

2. Insert a small paper clip or toothpick into the check valve, to hold it open during the test (remove after testing). Using a

rubber sheet or the palm of your hand to seal the end of the threaded tube, pressurize the calibration port to 10-15" H

2

O.

The detector should hold pressure. If the pressure drops, replace the detector.

All detectors are inspected and pressure tested before shipment. The reason for the broken cell could be:

• Dropped during shipping, receiving, or installation.

• Hit with liquid water when hot.

Loading...

Loading...