5-88 Troubleshooting – ZP Oxygen Analyzer Troubleshooting

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

TT

RR

OO

UU

BB

LL

EE

SS

HH

OO

OO

TT

II

NN

GG

Re-seek limits on servo; valve may need to be loosened or re-greased (if re-greasing the valve, re-seek servo limits

afterward, as there will be a change in the torque exerted by the servo). See section "Servo Setup" on page 3-47 for more

information.

• Servo limit switch too close to curve points.

Servo limit switches are not as repeatable as the servo feedback pot. If a servo limit switch trip position shifts and

stops the servo motor before the desired curve position is reached, a not at position lockout can occur. All servo limit

switches must activate at least 2 degrees away from the closest curve point. See section "Servo Setup" on page 3-47 for

more information.

• If oxygen trim is enabled, The FD damper servo open limit switch should be set 17-20% higher than the highest curve

point. This allows the O

2

Trim to increases the airow at high re without tripping the open limit switch.

Example: Calculate 20% as follows: If the FD damper curve ranges from 13.0-79.0 degrees, the span is 66 degrees.

20% of 66 deg = 13.2 deg. The open limit switch should be set to 92.2 degrees (79 + 13.2), or higher.

ZP Oxygen Analyzer Troubleshooting

ZP Wet Measurement Vs. Dry Measurement

The most common issue encountered is that the ZP % oxygen does not match the % oxygen measured by a portable or extractive

oxygen analyzer. This is normal and the two measurements should not be the same. A dry % oxygen measurement will always be

higher than a wet % oxygen measurement of the same ue gas.

• Wet Measurement (ZP): The ZP detector cell is located inside the ue gas and measures oxygen as a percentage of all

the ue gas component gases (O

2

, N

2

, CO

2

, CO, H

2

O). This is known as a wet oxygen measurement because the water

vapor occupies a substantial percentage of the total volume of the ue gas.

• Dry Measurement (Portable & Extractive): A portable oxygen analyzer or an EPA CEM oxygen analyzer extracts a sample

of the ue gas from the duct and transports it to a measurement device that is located outside of the duct. Since the

temperature of the connecting tubing and/or the external measurement cell is below the dew point (that is, condensation

temperature) of the water vapor in the ue gas sample, the water vapor in the ue gas condenses. Oxygen is measured

as a percentage of the dry ue gas component gases (O

2

, N

2

, CO

2

, CO). This is known as a dry oxygen measurement

because the condensed water occupies a negligible percentage of the total volume of the ue gas.

Natural Gas Wet = 0.888 * Dry Dry = 1.125 * Wet

#2 Oil through #6 Oil Wet = 0.930 * Dry Dry = 1.075 * Wet

Coal, Wood, Solid Fuels Varies widely based on the moisture content of the fuel as it's burned.

Table 5 – 2 Approximate Wet Vs. Dry Correction Factors

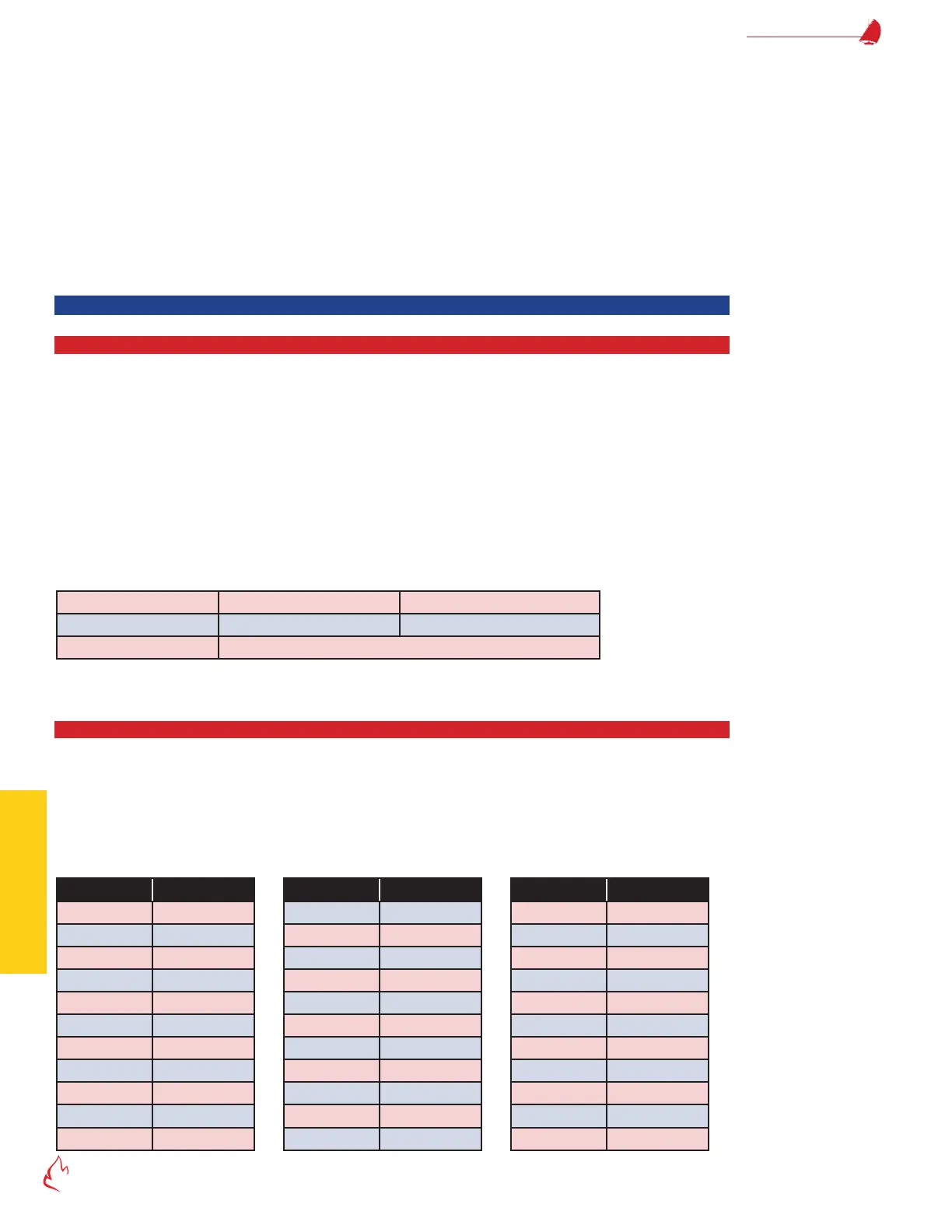

Normal Operating Values

The Values below are approximate for a new detector at 800 °C with 20.6% reference O

2

and are provided for troubleshooting

purposes. The values for each individual ZP Sensor will vary somewhat. As the detector ages, the mV values get smaller. All ZrO

2

sensors should be checked and/or re-calibrated 1-2 times per year with certied calibration gases.

Cell Thermocouple (type R) – 7.8 - 8.0 mV – (terminals 143-144)

Cell Heater – 45 - 55 ohms – (terminals 81-82)

Cell mV for various Oxygen Concentrations are shown in "Table 5 – 3 Cell mV Vs. % Oxygen", below – (terminals 145-146)

% Oxygen Cell mV

0.01 168.15

0.05 132.68

0.1 117.41

0.5 81.94

1.0 66.67

1.2 62.65

1.4 59.25

1.5 57.73

1.6 56.31

1.8 53.71

2.0 51.39

% Oxygen Cell mV

2.2 49.29

2.4 47.37

2.6 45.61

2.8 43.98

3.0 42.46

3.5 39.06

4.0 36.12

4.5 33.52

5.0 31.20

5.5 29.10

6.0 27.18

% Oxygen Cell mV

6.5 25.42

7.0 23.79

7.5 22.27

8.0 20.84

9.0 18.25

10.0 15.93

11.0 13.83

12.0 11.91

13.0 10.14

14.0 8.511

15.0 6.991

Loading...

Loading...