Troubleshooting – ZP Oxygen Analyzer Troubleshooting 5-89

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

TT

RR

OO

UU

BB

LL

EE

SS

HH

OO

OO

TT

II

NN

GG

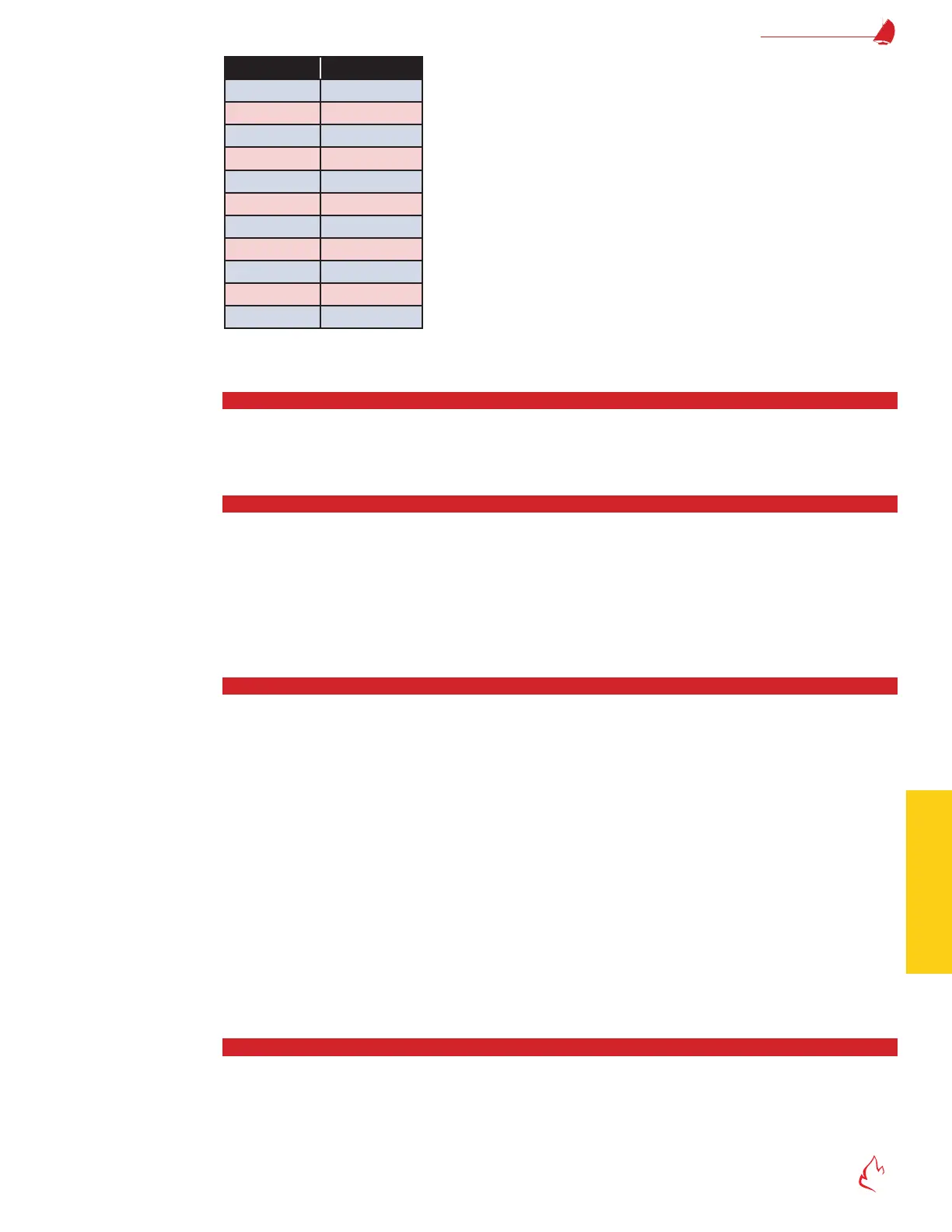

% Oxygen Cell mV

16.0 5.569

17.0 4.233

18.0 2.973

19.0 1.782

20.0 0.651

20.6 0.0

21.0 -0.4238

22.0 -1.449

23.0 -2.428

24.0 -3.366

25.0 -4.266

Table 5 – 3 Cell mV Vs. % Oxygen

Slow Response Time

• Check for excessive dirt on the detector lter or inside the probe.

• As the cell approaches the end of its life, the cell impedance increases toward 1100 ohms, and the cell response time

becomes longer.

Reading is Lower than Expected

• See "ZP Wet Measurement Vs. Dry Measurement".

• Check for CO or combustibles in the ue gas. CO or combustibles will oxidize on the internal surface of the cell. This

consumes the oxygen locally within the detector and causes a low reading.

• Check with certied calibration gas.

• Check to see if the lter is dirty or blocked.

• Check for detector leaks.

Reading is Higher than Expected

It is important to remember that the cell makes a differential measurement. That is, the cell compares the unknown oxygen

percentage in the ue gas against the known oxygen percentage in the ambient air inside the cell. Ambient air is typically 20.6%

oxygen; however, it can range from 19.5% to 20.9% as relative humidity and temperature change.

If the ue gas duct is pressurized and a duct leak allows ue gas to enter the detector head, the ambient oxygen percentage

can be substantially lower. Combustible gases in the ambient air will consume the oxygen on the surface of the cell and will lower the

percent oxygen in the ambient air inside the cell. If the ambient oxygen percentage inside the cell is low, a zirconia cell will sense a

lower differential and will cause the analyzer to indicate a higher oxygen level than is in the ue gas.

If the ceramic cell is dropped and cracks, the measured ue gas and ambient air will intermingle, and the oxygen percentage

on both sides of the cell will equalize. A zirconia cell will sense a lower differential and will cause the analyzer to indicate a higher

oxygen level than is in the ue gas.

• See "ZP Wet Measurement Vs. Dry Measurement".

• Check with certied calibration gas.

• Verify that the calibration gas port and tubing are plugged or closed during operation to prevent inltration of air.

• Check to see if the lter is dirty or blocked.

• Check for detector leaks.

• Check the AC line voltage; it must be 60 Hz and greater than 102 volts.

• Check the AC line voltage for excessive electrical noise.

Loading...

Loading...