2-22 Installation – Servo Installation

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

II

NN

SS

TT

AA

LL

LL

AA

TT

II

OO

NN

The proprietary digital communication protocol allows the servos to be daisy chained to the FlexFit chassis in any order. This

allows the installing contractor to wire the servos in the best way to allow the shortest and cleanest conduit runs. The commissioning

engineer assigns each servo an address and a function during the setup procedure.

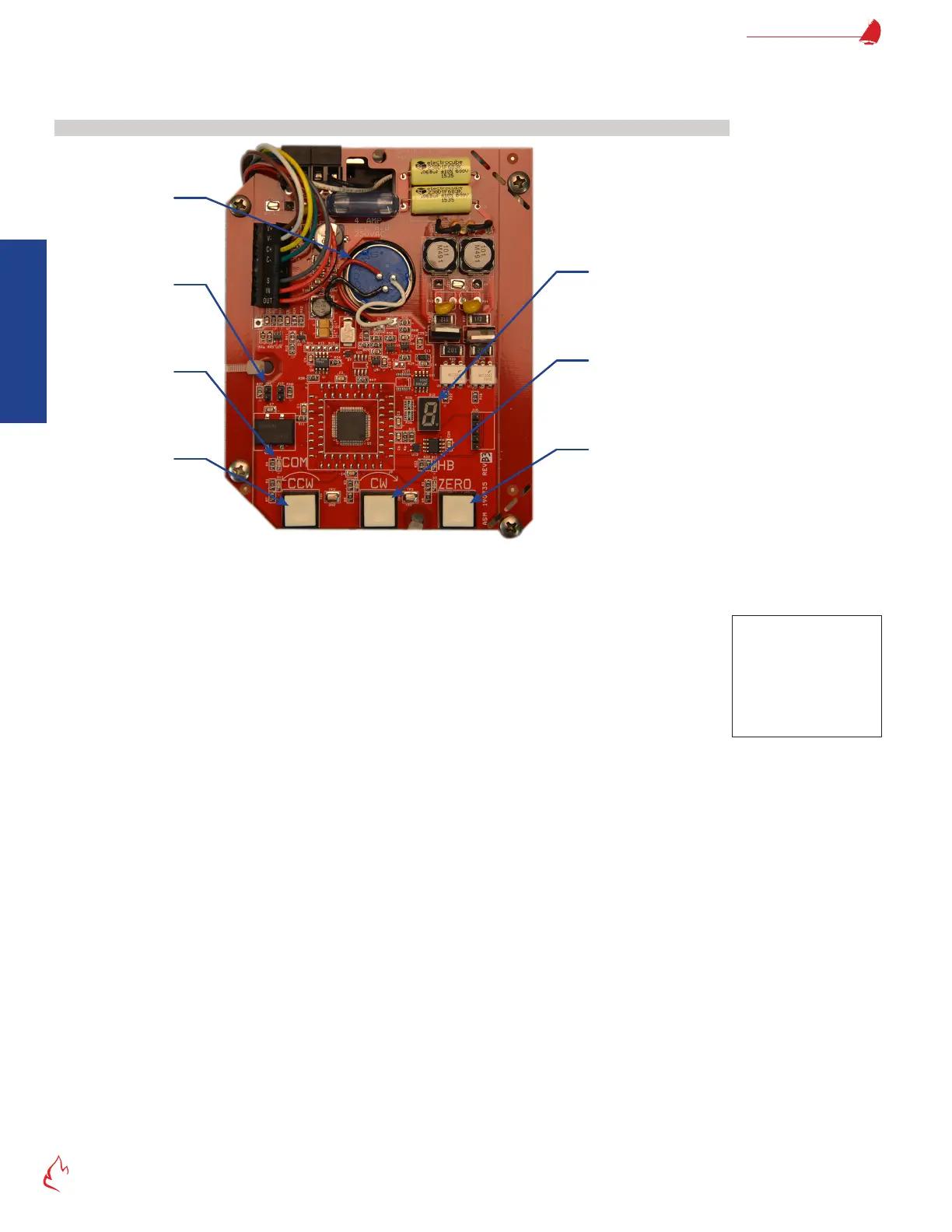

Servo Control Board

Figure 2 – 9

Clockwise “Jog”

Pushbutton

Zero PushbuttonCounterclockwise

“Jog” Pushbutton

Jumper J11

Feedback

Potentiometer

Servo Control Board

The servo board contains three pushbuttons that are used to manually position and zero calibrate the servo.

• CCW – Counter-Clockwise – drives the servo in the CCW direction

• CW – Clockwise – drives the servo in the CW direction

• ZERO – Sets up the servo address and the direction the servo travels to close

Five LED’s provide a continuous status indication of the servo operation.

• CCW LED – ON = Servo motor is being driven counter-clockwise (all modes)

• CW LED – ON = Servo motor is being driven clockwise (all modes)

• ZERO LED – The FlexFit combustion control board has activated the servo zero calibration mode.

Blinking = in zero cal mode, zero position has not been established

ON = in zero cal mode, zero position has been established

• COMM LED – Indicates the status of communication between the servo and the FlexFit

ON = Servo motor is communicating with the FlexFit (all modes)

OFF = The FlexFit has not sent a message to this specic servo for >1 second.

• HB LED – Indicates if the servo is working properly

Blinking 2 times/second = no error

Blinking faster = error

Note

CCW & CW are only active

when the ZERO calibration

mode is active, the servo

is not communicating

with the FlexFit, or the

J11 jumper is removed.

Loading...

Loading...