5-86 Troubleshooting – Lockout Data

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

TT

RR

OO

UU

BB

LL

EE

SS

HH

OO

OO

TT

II

NN

GG

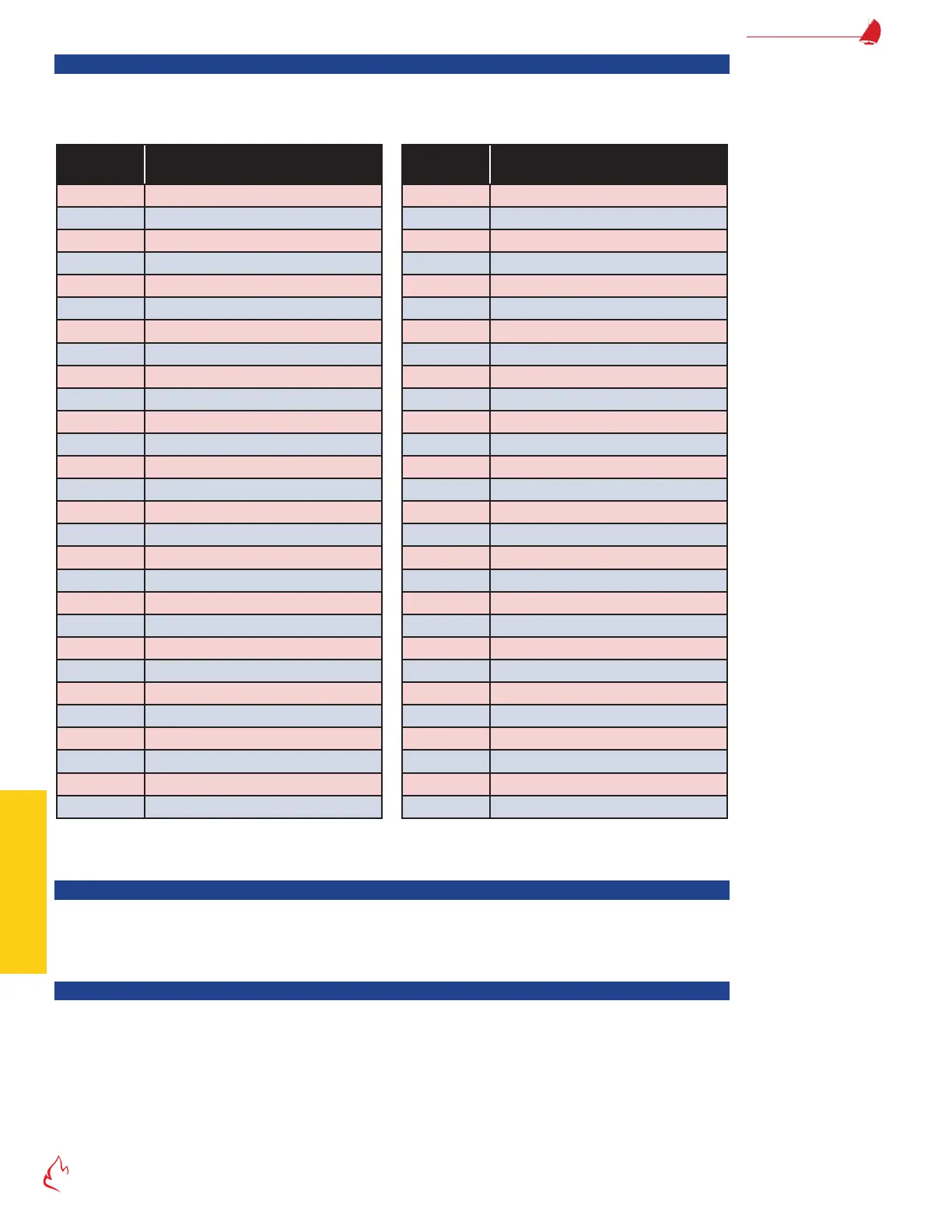

Lockout Data

If the condition results in a lockout, a snapshot of the value of virtually every input, output, servo and sensor at the time of the

lockout is stored in the FlexFit memory. Time/date stamped lockout data for each of the last 10 lockouts can be viewed via the LCD

by going to Main Menu > Lockout Data. "Table 5 – 1 Lockout Messages" lists the lockout message data.

Table 5 – 1 Lockout Messages

Message

Number Message Data

0) LOCKOUT

1) BMS State

2) Selected Fuel

3) Scanner 1 %

4) Firing Rate % FB

5) Flue Temp

6) Boiler Outlet Temp/Press

7) O2 Trim PID SP

8) Oxygen

9) O2 Analyzer Normal

10) O2 Trim

11) Scaled O2 Trim

12) Draft

13) Pilot Test Hold

14) Commission Mode

15) Password Level

16) Fuel Demand deg

17) Fuel Feedback Position

18) FD Servo SP

19) FD Servo FB

20) FD VSD Hz SP

21) FD VSD Hz FB

22) FGR Servo SP

23) FGR Servo FB

24) Aux 1 Servo SP

25) Aux 1 Servo FB

26) Aux 2 SP

27) Aux 2 FB

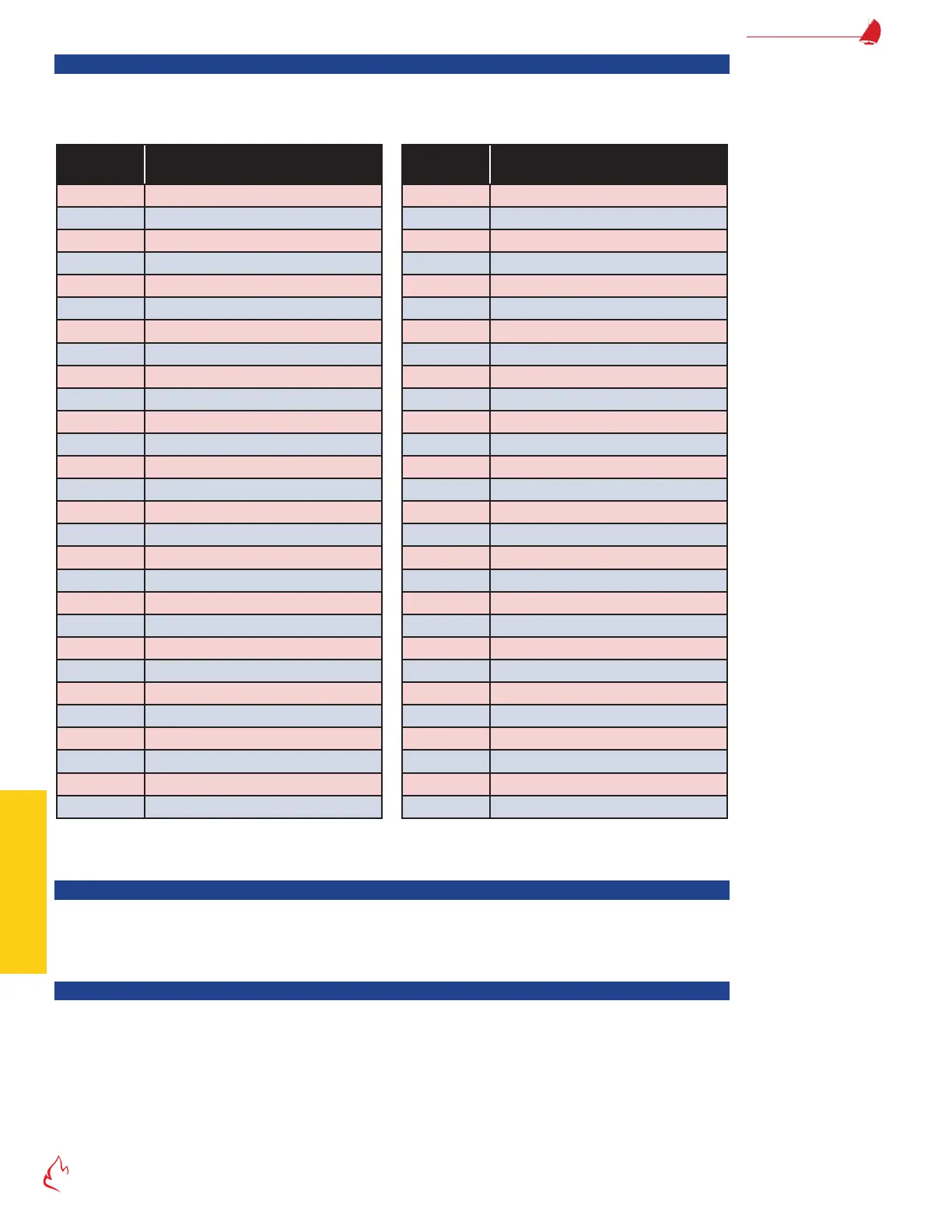

Message

Number Message Data

28) Aux 3 SP

29) Aux 3 FB

30) Draft Servo SP

31) Draft Servo FB

32) Boiler Demand % 135 Ohm/4-20 P7810

33) Remote SP, Firing Rate PID

34) Local SP, Firing Rate PID

35) Firing Rate % Command

36) DI Flame Detected Relay

37) DI Running Interlocks

38) DI FD Fan Type

39) DI Start limits

40) DI Leak Test PS

41) DI Low Fire Switch

42) DI Purge Flow / High Fire Switch

43) DI SSOV POC

44) DHW Start

45) Warm Standby LFH

46) FGR LFH Active

47) Light Off LFH Active

48) Cold Start Cycle Active

49) DHW Override Active

50) Modbus Comm Bad

51) RO Ign Xfmr

52) RO 10s Pilot

53) RO MV1 SSOV

54) RO 15s Pilot/MV2

55) RO FD Fan

I/O Data Display

Navigating to Main Menu > Utilities > I/O Data Display provides a means to view the real-time value of every FlexFit eld wiring

120 VAC input, analog input, and relay output. This provides a means to simultaneously test eld device operation, eld wiring, and

control hardware operation.

Electrical Noise

Electrical noise is a common problem with burner circuitry because of the mix of 120 VAC, low voltage DC, variable speed

drive (VSD) fan motors, and 5,000 to 10,000-volt ignition transformer circuits. Sporadic shutdowns, lost or corrupt data, controller

reboots, and "Internal Error" messages can be caused by electrical noise. If you suspect electrical noise problems, inspect the boiler

wiring for the following issues:

• The shields of all 4-20 mA / 0-5 VDC, Thermistor, Thermocouple, Servo and LCD communications, and scanner cables

should be connected at one end only, as shown on the wiring schematics. All shield foils, braids, and shield drain wires

should be insulated (with either tape or heat shrink) to prevent connections to earth or power ground. Shielded cables

that have been pulled through under-sized conduits or ttings with excessive force can have a torn outer casing inside the

Loading...

Loading...