2-18 Installation – Combustion Control Installation

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

II

NN

SS

TT

AA

LL

LL

AA

TT

II

OO

NN

Combustion Control Installation

1. Be sure you have read the notes in section "Electrical Noise Suppression" on page 2-12 and section "Installation Warnings

and Notes" on page 2-13.

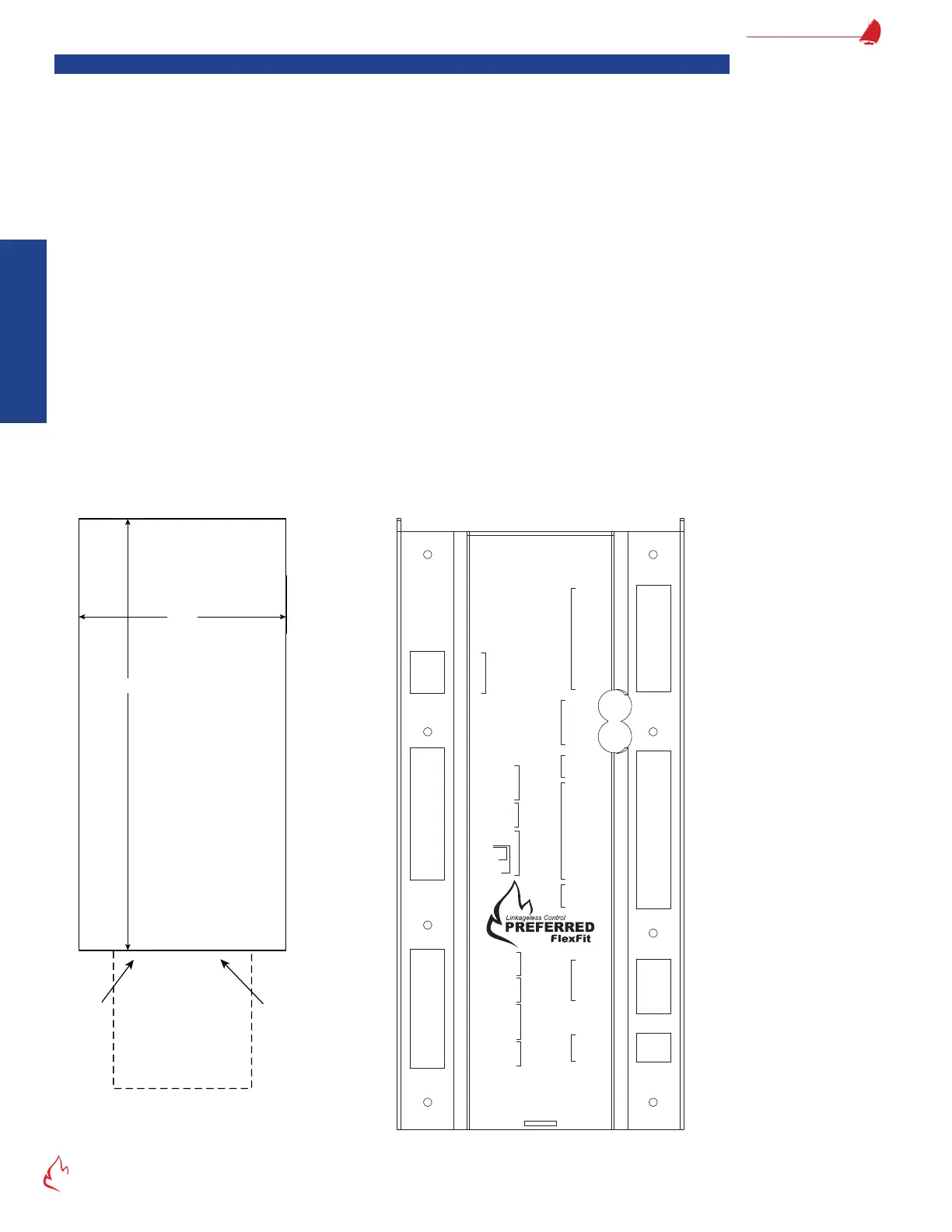

2. Begin by selecting the location for the combustion control keypad/display, and cut a rectangular opening using "Figure

2 – 4 LCD Cutout Dimensions" as a guide.

3. Place the FlexFit-CC into the cutout location and secure it to the door using the provided cinch brackets.

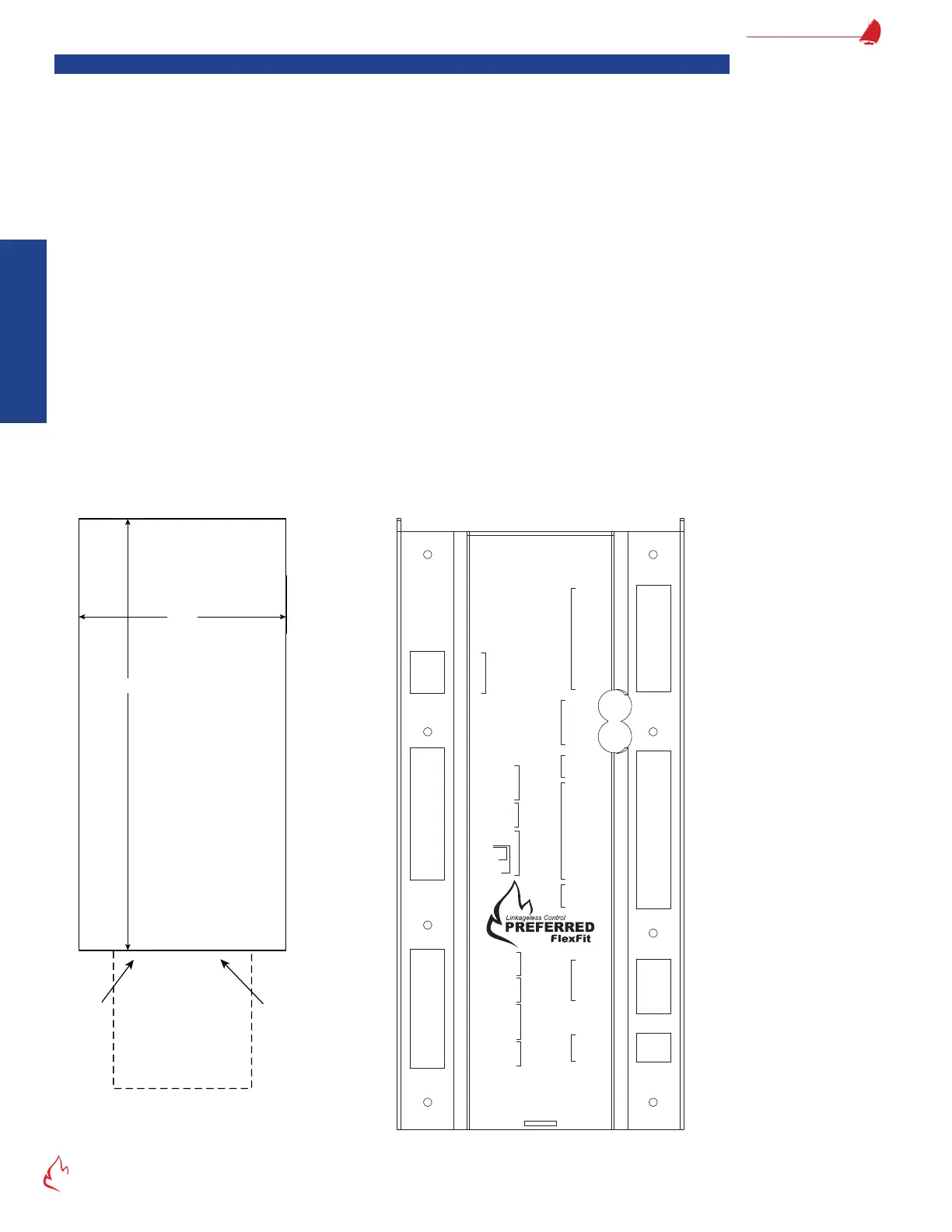

4. During installation, refer to "Figure 2 – 6 FF-CC Wiring Diagram (Typical)" on page 2-19, for a wiring diagram.

5. If a 135-ohm controller is used, wire it to terminals B, R, and W, as shown in the wiring diagram. A ring rate motor is not

needed as the FlexFit will drive the servos as necessary, based on the input.

6. If not using a 135-ohm controller, a boiler outlet sensor may be wired to terminal 108 through 111 as shown in the wiring

diagram. A 135-ohm controller and a boiler outlet sensor may not both be wired to the FlexFit at the same time.

7. See section "Servo Installation" on page 2-21, for servo installation instructions.

8. If using the Preferred Instruments oxygen sensor, see section "ZP Oxygen Sensor Installation" on page 2-32, for ZP

Oxygen Sensor Installation.

9. Continue with the installation of VSDs, RS-485 devices, etc., referencing the FlexFit-CC wiring diagram and any other

included drawings or documentation.

10. Ensure the plug-in terminal blocks are properly inserted before applying power.

11. Connect the 9-pin D-Sub connector between the FlexFit-CC and the FlexFit BMS.

12. The USB port is used for connecting a personal computer, running the FlexFit Edit software, to read or write FlexFit

parameters.

Figure 2 – 4

4 1/2"

9 3/8"

FlexFit-CC

Keypad/Display

Panel Cutout

Enclosure

1.6" deep

behind Panel

"B"

Port

Cable

3" x 3"

Clearance

behind Panel

for Cables

FF-CC Keypad/Display

External Size: 9.9" x 5.1" x 0.38"

LCD Cutout Dimensions

Figure 2 – 5

Oxygen SensorStack

Servos

135 ohm

Firing Rate

Modbus

Aux. Power

Input

3A Slow Blow

Pwr In

FD

VSDAux 2

4-20

In

4-20

Out

Aux 2

FD

VSD

4-20

In

4-20

Out

Draft

4-20

mA

Remote

Demand

4-20

mA

Boiler Outlet

4-20mA

TH

OUT

24V +

24V

‒

Comm +

Comm

‒

Shield

Servo N

Servo H

120V H 79

120V N 80

Htr N 82

S/G

T/C blk + 143

T/C red

‒

144

S/G

Cell

‒

145

Cell + 146

T/C wht + 147

T/C red

‒

148

RS485 +

RS485

‒

Common

24V + 106

24V

‒ 107

Servos

Oxygen

Sensor

GROUND

Htr H 81

R

182 Shield

181 +

180 24V

113

‒

112 +

111 Shield

110 +

109 5V

108 24V

135

‒

134 +

133

‒ SP

132 + SP

131

‒

130 +

129 24V

128

‒

FB

127 + FB

USB

Do Not Use

Alarm 63

W

B

BMS/CC Link

FlexFit-CC Rear View

Loading...

Loading...