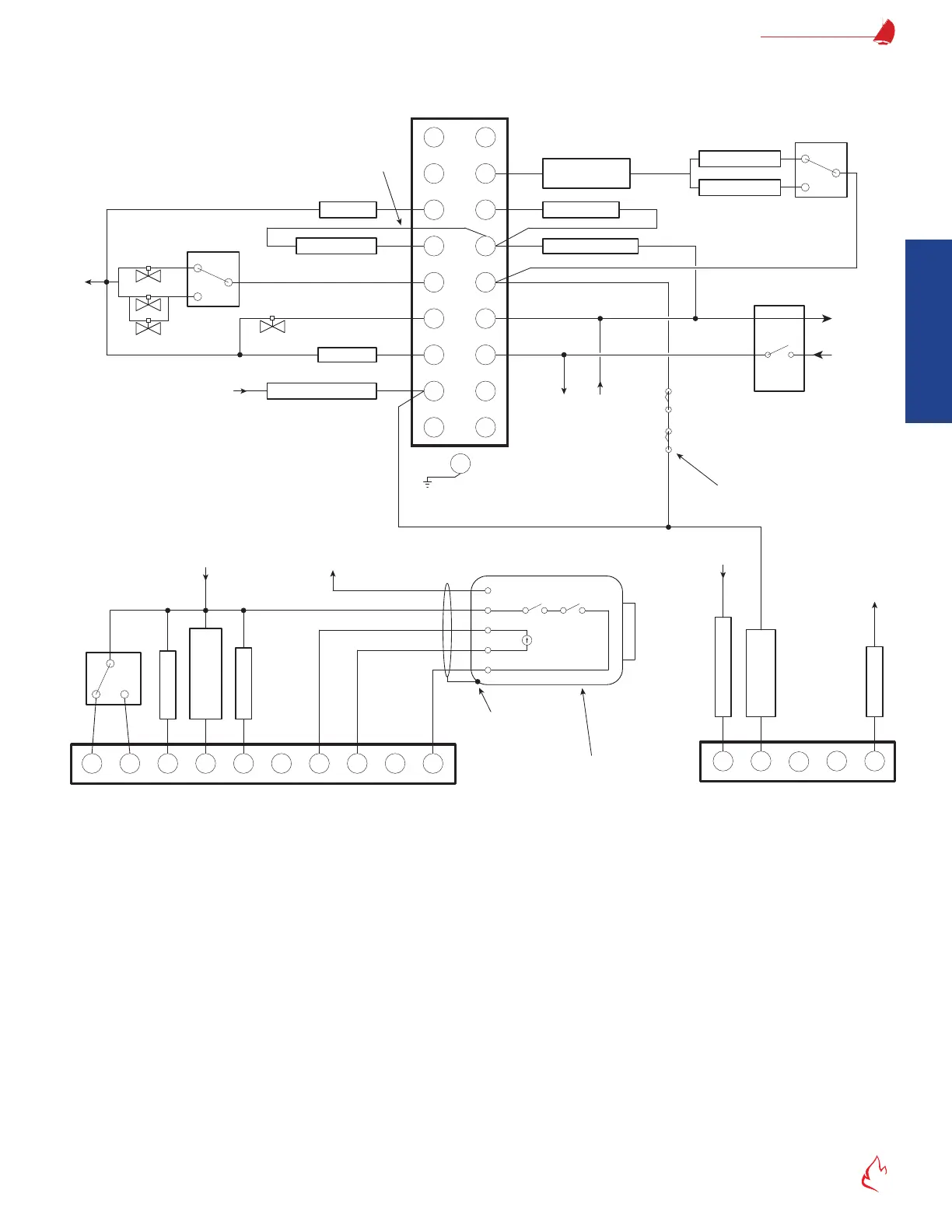

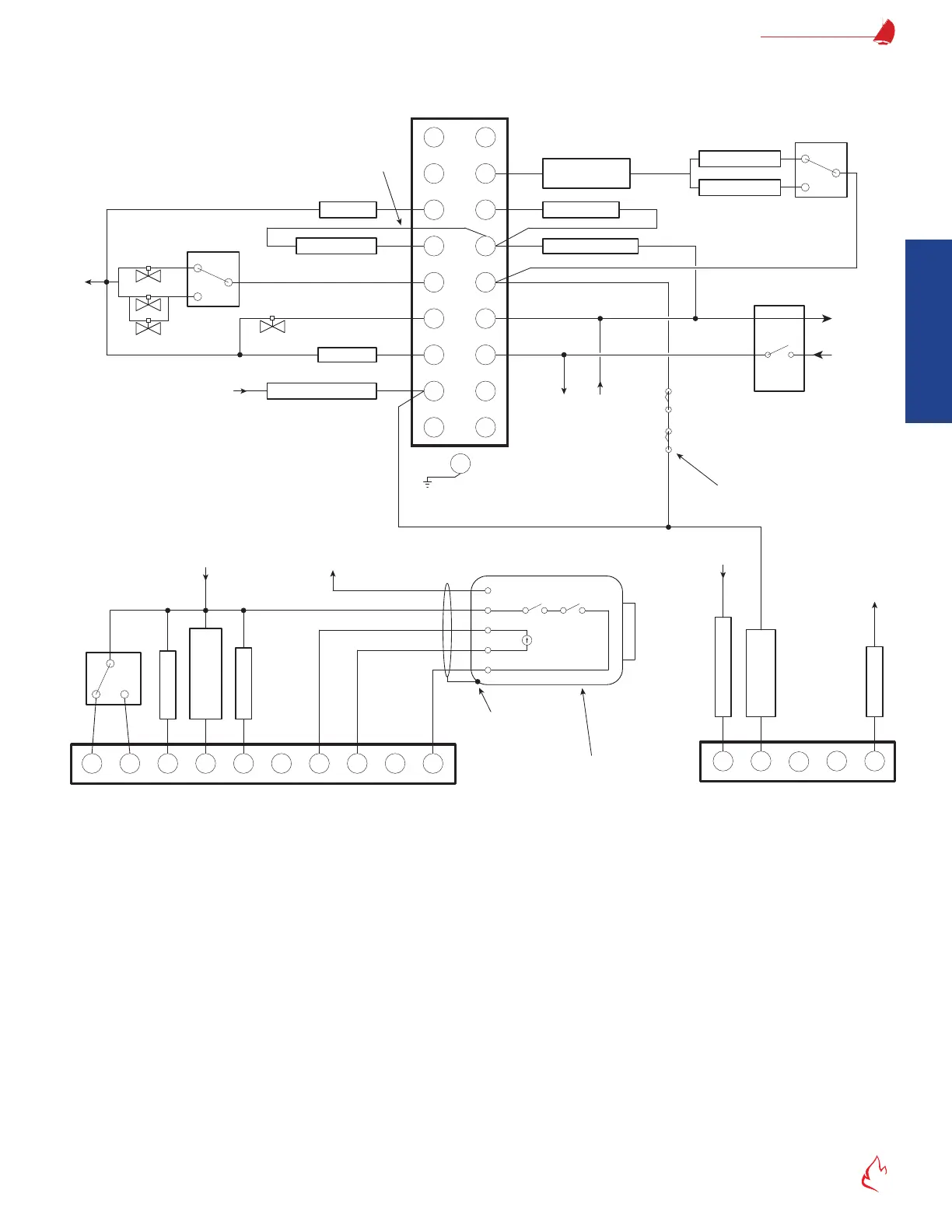

Installation – Burner Management System (Flame Safeguard) Installation 2-17

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

II

NN

SS

TT

AA

LL

LL

AA

TT

II

OO

NN

Figure 2 – 3 FF-11

X

Existing

Wiring Base

Low Fire Switch

High Fire Switch

120V Alarm

Start (Recycling) Limits

Running (Lockout)

Interlocks

Pilot Valve

Master

Switch

L1 (Hot)

L2 (N)

Fuel 1 POCS

Fuel 2 POCS

Fuel Select - 2

Fuel 1 Interlocks

Fuel 2 Interlocks

Pre-ignition Interlock

MV1/MV2 Fuel Valves

120V, 60 Hz Power Supply

Provide disconnect means and

overload protection as required.

FF-110 Flame Safeguard (BMS)

Flex Sequence Wiring (Typical)

*

*

†

Terminals 10, 11, 12, and X are

typically not used with the

FlexFit, but they perform the

same function as an E110.

S2

S1

12

G

10

11

***

If no main fuel valve SSOV has proof

of closure, then jumper terminal 13 to 3.

6

5

P

D

A

8

Fuel Select - 3

13

L2

3

M

†

†

†

†

7

For E110 retrofits, move

this wire from D to M.

L1

L1

L1

L2

MV2 Fuel Valve

Gas Valve MV2

(Downstream)

Do not wire to any unused terminals

unless noted otherwise.

**

**

Optional External

Call for Heat

Ignition Xfmr

N/AN/A

16

17

W

Upper Connector on BMS

L2

Leak Pressure Switch

L1

***

Gas Valve MV1

(Upstream)

Oil Valves

*Note: Disconnect any existing wires from

terminals S1 and S2; they are not used.

***Note: If leak test is not being used,

do not wire to terminals 6 and 16.

**Note: Remove the mod motor. If low fire proving

interlocks are used, then wire them from M to D. If

low fire proving is only by servo, then jumper M to

D. If high fire proving interlocks (including purge air

flow) are used, then wire them from M to 8. If high fire

proving is only by servo, then jumper M to 8.

For direct spark ignition, do not jumper

terminals 6 to 7. Wire as shown and use

the flex sequence parameters to control

DSI and timing settings.

Burner Motor (Fan)

Example:

Fuel 1 = Gas

Fuel 2 = Oil

Remote Reset

LFH, DHW CFH,

or Warm Standby

FD Fan Mode

F

uel

1

F

ue

l

2

120V = Fixed Speed

0V = VSD

+24V Out

4-20mA In

Upper Connector on BMS

Fuel Select - 1

Flame On

Flame Intensity

A

B

C

D

E

Isolated

Loop Powered

4-20mA Output

Neutral

Hot

120V Output

Flame Scanner

OR

YL

RD

BL

BK

N/A N/A

BMU-UVSC, BMU-UV,

or BMU-IR

Ground to Scanner

Metal Body

FRFl-Fl+

2827262524

L1

L2

0 BMS Flex Sequence Wiring Diagram (Typical) (Field Selectable)

Loading...

Loading...