1-10 Description – Combustion Control System

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

DD

EE

SS

CC

RR

II

PP

TT

II

OO

NN

• Oxygen Trim – compares the oxygen levels in the ue gas to a value determined during commissioning and will implement

control actions to correct the error

• Draft Control – maintains a constant furnace or boiler outlet draft pressure (positive or negative) as the boiler ring rate

modulates from low to high re and as outdoor weather conditions change the draft effect

Parallel Positioning

In this system, both the fuel valve(s) and the air damper each have their own servo(s). Each servo is equipped with a position

feedback potentiometer. Unlike a jackshaft position system where every device is mechanically linked, the individual servos can be

electronically characterized for greater fuel/air ratio control accuracy.

The parallel positioning system is also safer as the FlexFit continually monitors the demand to the servo versus the feedback

potentiometer and will trip the burner should discrepancies be detected.

With a parallel positioning system, the adaptation of ue gas oxygen trim becomes an easier task. Instead of the added cost

of a link trim servo, the compensation for oxygen trim is performed by manipulation of the demand signal to the air damper servo.

Other advantages of parallel positioning over jackshaft positioning are that a Variable Speed Drive (VSD) can be used to save

energy and provide another means of oxygen trim.

Parallel positioning is especially suitable for larger boilers as all the control devices no longer must be in close proximity to a

common jackshaft. Fans, VSDs, and dampers can now be located distributed throughout the boiler room.

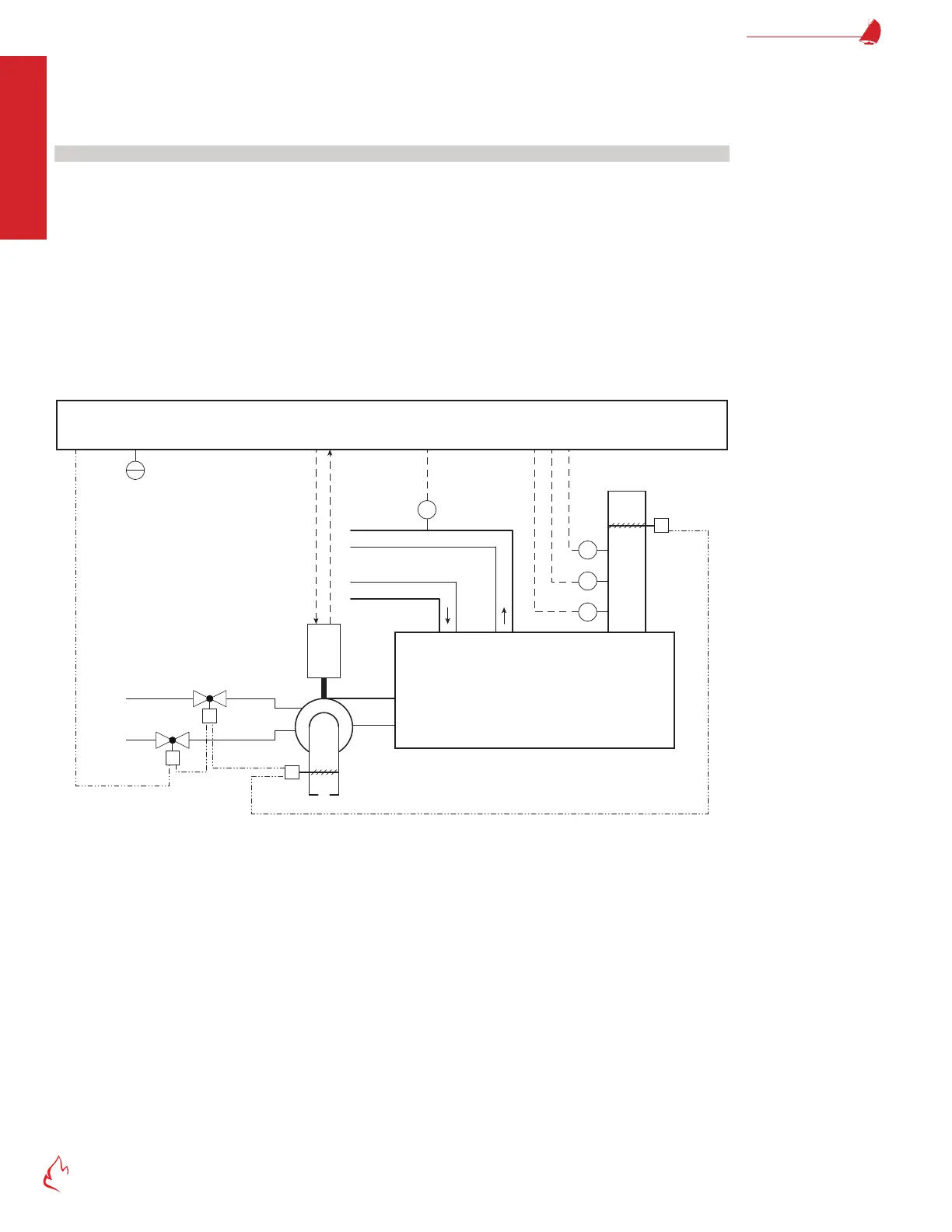

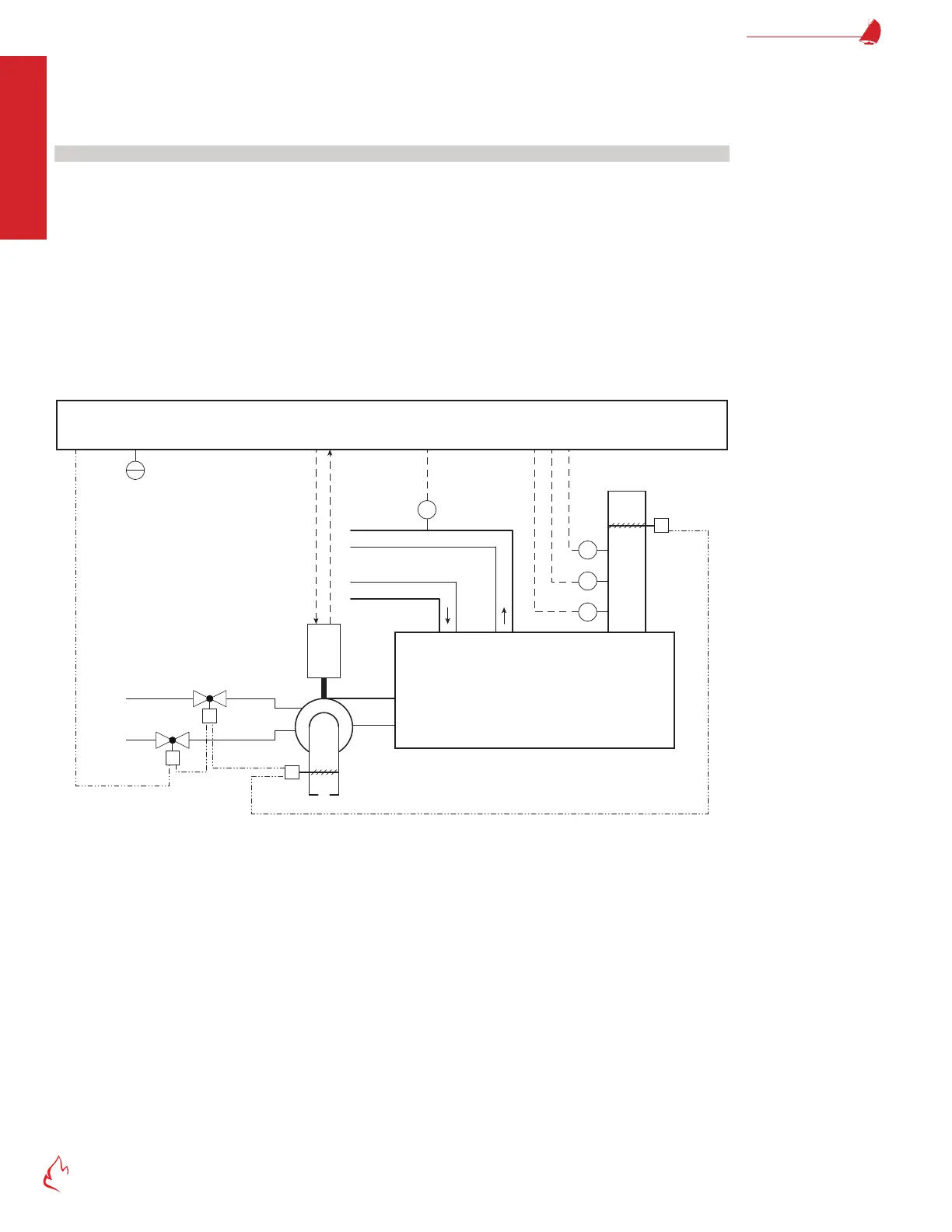

Figure 1 – 5

FlexFit Parallel Positioning (Hot Water Boiler)

Hot Water Boiler

S

S

S

Oil

Gas

VFD

S

PT

AE

TE

Servos

TE

4-20mA

Plant Master

Demand

Hot Water Supply

Hot Water Return

Water

Temp.

Flue

Temp.

Draft

Oxygen

FlexFit Parallel Positioning Example

Loading...

Loading...