Parameters 4-77

FlexFit – Linkageless Control – Revision 1.0

PREFERRED

UTILITIES MFG CORPORATION

PP

AA

RR

AA

MM

EE

TT

EE

RR

SS

P3.7.2 hIgh FIre lIMIter, 0-100%

Menu > Advanced Settings > Firing Rate Settings Password Level: Operator Restricted? No

Determines the high re setpoint to which the FlexFit will limit the ring rate.

Options: 30 to 100 [Default 100]

Note "High Fire Limiter, 0-100%" is manually set by the operator.

P3.7.3 +/- aVoId gaP, FIrIng rate

Menu > Advanced Settings > Firing Rate Settings Password Level: Technician Restricted? No

This determines by how much an avoid position is jumped over in the ring rate. Some burner/boiler combinations have an audible

rumble at a specic ring rate due to resonant vibrational energies. If an avoid fuel position was stored in the combustion curve data,

the FlexFit will jump over the avoid ring rate within the range of the "+/- Avoid Gap, Firing Rate".

Options: 0.2 to 5.0 [Default 1.5]

Draft Control

Draft is the term used to describe the movement of gases, usually the products of combustion, through a ue or chimney. The

measurement of draft is expressed in inches water column ("WC) and represents the difference in weight of ue gas and a corre-

sponding column of outside air. The objective of draft control is to maintain a constant furnace or boiler outlet draft pressure (positive

or negative) as the boiler ring rate modulates from low to high re and as outdoor weather conditions change the draft effect.

Typically, the draft pressure is sensed and controlled at either the boiler outlet or in the furnace. A high-quality draft range

transmitter is used to provide a reliable measurement of the draft. Because draft signals are inherently noisy (constantly moving),

it is common to lter the draft signal before it goes to the control block within the controller. However, caution must be used as too

much ltering will result in sluggish control. The draft transmitter should always be located physically higher than the sensing point,

and the sensing lines should be sloped so that condensation in the tubes runs back to the boiler. If the transmitter must be located

below the sensing point, a drip leg, condensation pot, and drain valve should be provided.

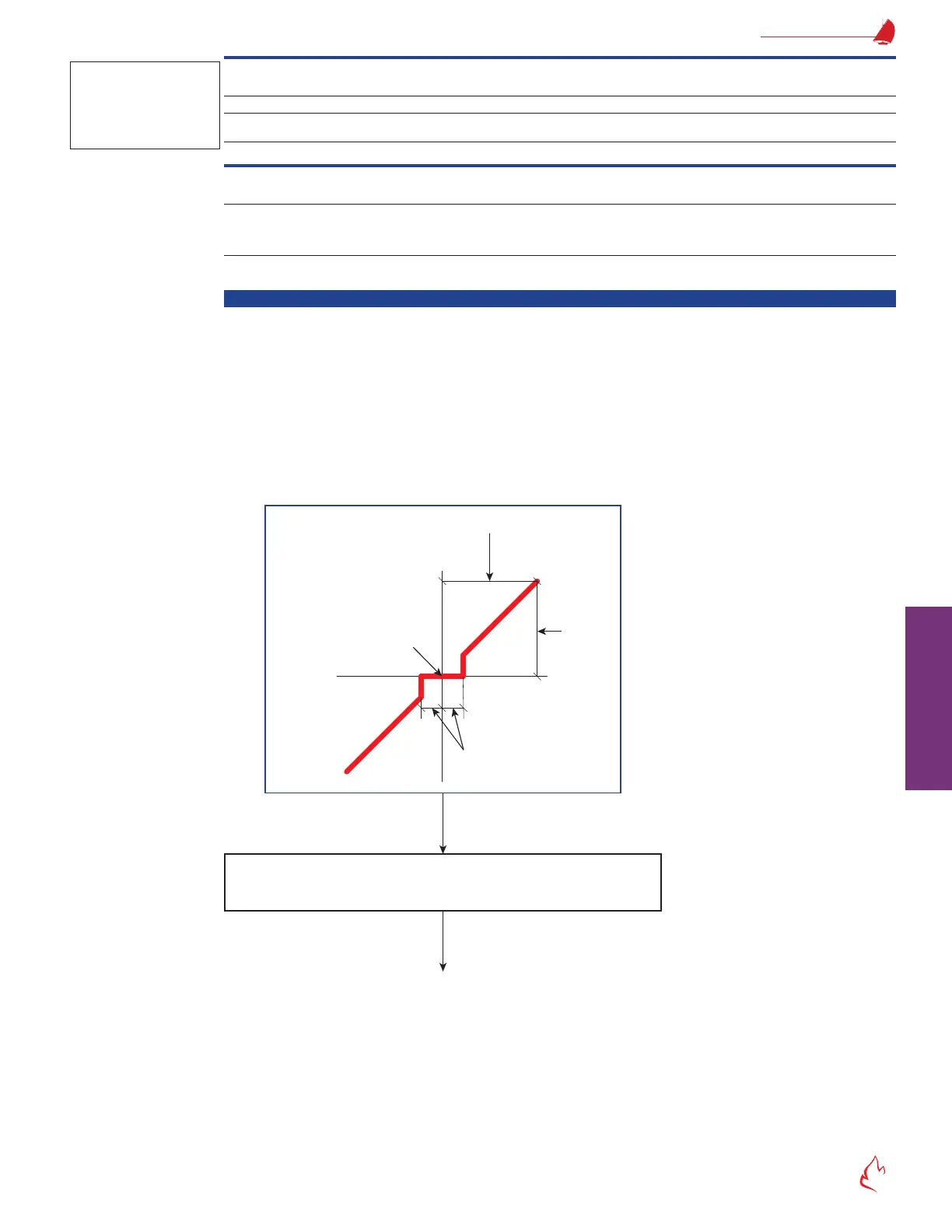

Figure 4 – 6

Error

Measured

Draft

Floating Draft

Set-point

Deadband, Draft (x2)

1/2 Proportional Band, Draft

Max Move per Scan

(based on Sec/90 Deg

Damper Rate Limit, Draft)

+

+

-

-

Once in automatic, the draft damper is positioned to decrease the error

signal (getting it closer to zero) while limiting the maximum servo speed

and not exceeding the minimum and maximum damper positions.

Error

Damper Position

Floating Draft Control

The FlexFit can accomplish draft control by positioning a boiler outlet damper (also called a stack damper) or the damper at either

the inlet or outlet of an Induced Draft (ID) fan. By utilizing oating control, the FlexFit will maintain draft at a setpoint as determined

during boiler commissioning. If the draft error (measured draft minus setpoint) is inside the deadband (see parameter "P4.2.2 Dead-

band, Draft"), the draft damper output doesn't change. If the draft error is outside the deadband, the draft damper position is adjusted

proportionally to the draft error until draft has returned to within the deadband. Additional draft control features include the following:

• Adjustable Purge Positions – Parameter "P4.1.2 Outlet Damper Purge Position" allows the user to set the outlet damper

position for boiler purge.

Note

This does not affect

combustion curves.

It only limits the

maximum ring rate.

Loading...

Loading...