4

Installation

Braking resistors

Operating Instructions – MOVIDRIVE

®

modular

113

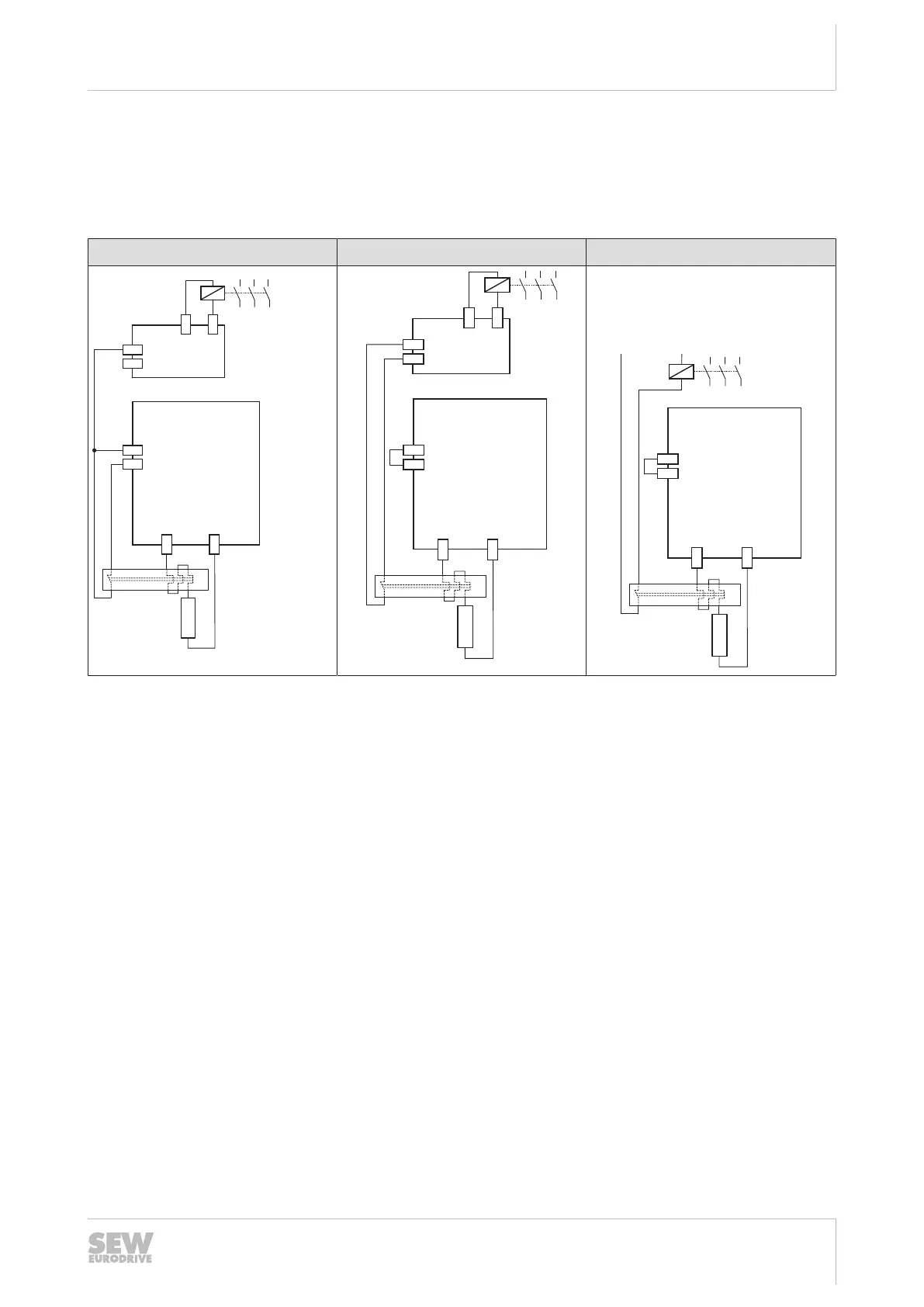

External bimetallic relay

MDP90A-0100-.. power supply module

If an external bimetallic relay is used with a 10kW power supply module, there are 3

possible connections.

Connection 1 Connection 2 Connection 3

MDP90A

X7:2 -Temp_R

X7:1 +Temp_R

[2]

X3 +R

X3 -R

PLC

DI

24 V OUT

DO

GND

[1]

9007214215763467

MDP90A

X7:2 -Temp_R

X7:1 +Temp_R

X3 +R

X3 -R

[2]

PLC

DI

24 V OUT

DO

GND

[1]

MDP90A

X7:2 -Temp_R

X7:1 +Temp_R

X3 +R

X3 -R

[2]

[1]

[1] Line contactor

[2] Braking resistor

Note that the reference potential GND of the digital input control must be the same as

the reference potential of the application inverter when connection 1 is used.

• Connection 1

– If the thermal circuit breaker trips, the signal in the power supply module and in

the PLC is evaluated.

– If the thermal circuit breaker trips, the PLC must interrupt the power supply.

– If the thermal circuit breaker trips, the power supply module switches all axis

modules to "Output stage inhibit".

• Connection 2

– If the thermal circuit breaker trips, the signal in the PLC is evaluated.

– If the thermal circuit breaker trips, the PLC must interrupt the power supply.

– If the thermal circuit breaker trips, there is no response in the power supply

module and the axis modules.

– With connection 2, it is possible that the PLC finishes the current travel cycle al-

though the thermal circuit breaker has tripped. Only then, the power supply is

disconnected. In this case, the residual braking energy W

Rest

= P

BRnom

× 20 s

must not be exceeded.

• Connection 3

– If the thermal circuit breaker trips, the signal directly affects the line contactor.

24748536/EN – 11/2017

Loading...

Loading...