9

Functional safety

Safety Conditions

Operating Instructions – MOVIDRIVE

®

modular

258

9.3.4 Requirements on startup

• To validate the implemented drive safety functions, they must be documented and

checked after successful startup (validation).

• Observe the restrictions for drive safety functions in chapter "Restrictions" for the

validation of the safety functions. Non-safety-related parts and components that af-

fect the result of the verification test (e.g. motor brake) must be deactivated, if ne-

cessary.

• For using the application inverter in safety-relevant applications, it is essential that

you perform and record startup checks for the disconnecting device and correct

wiring.

9.3.5 Requirements on operation

• Operation is only allowed within the limits specified in the data sheets. This prin-

ciple applies to the external safety controller as well as the application inverter and

approved options.

• The built-in diagnostic function is limited in case of a permanently enabled or per-

manently disabled STO input. Only with a level change of the STO signal, exten-

ded diagnostic functions are performed. This is why the drive safety function via

STO input must be triggered with connected line voltage at least once every 12

months for PL d according to EN ISO 13849‑1 and SIL 2 EN 61800-5-2 and at

least once every 3 months for PL e according to EN ISO 13849‑1 and

SIL3EN61800‑5‑2 to achieve a complete test coverage. Adhere to the following

test procedure.

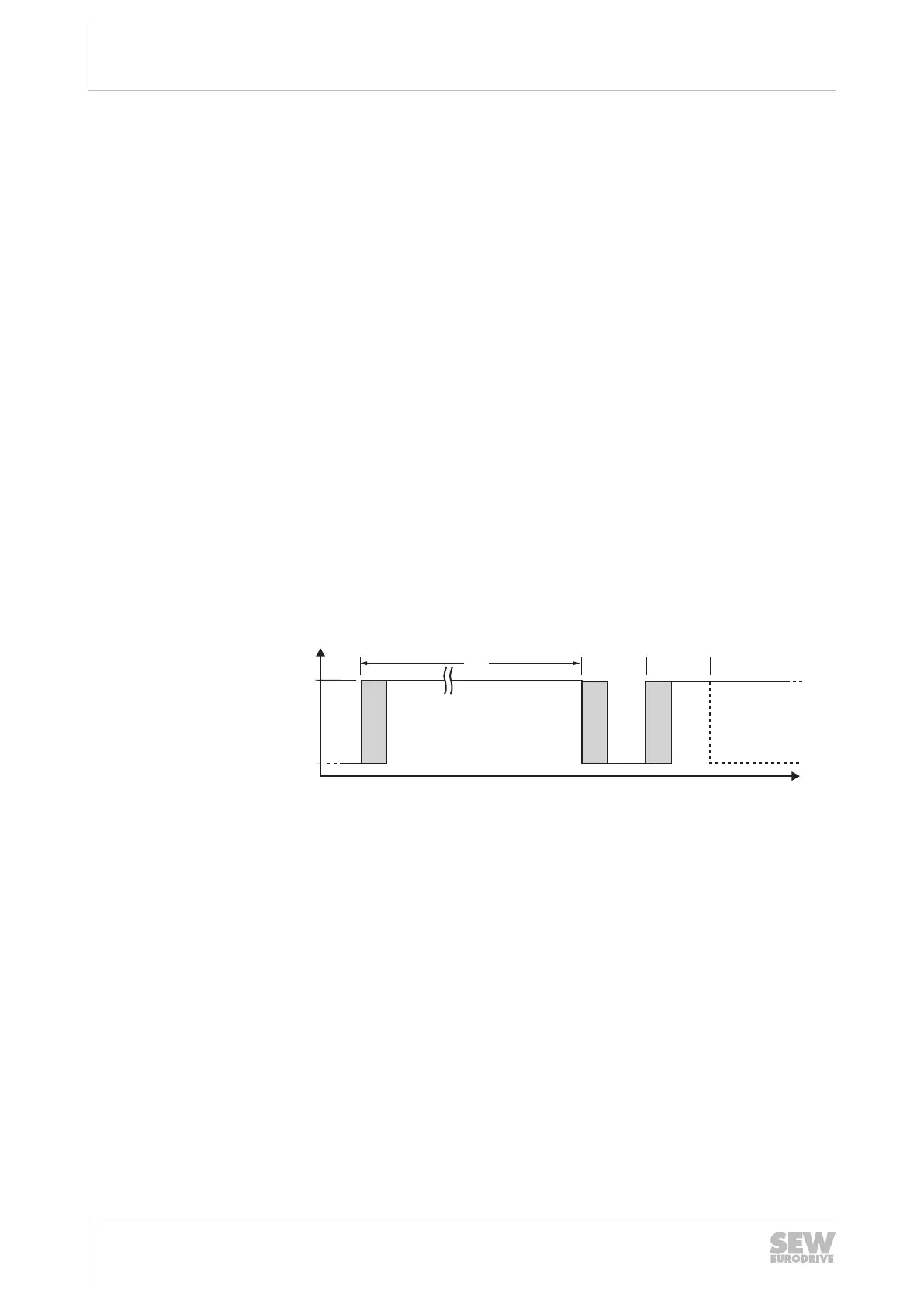

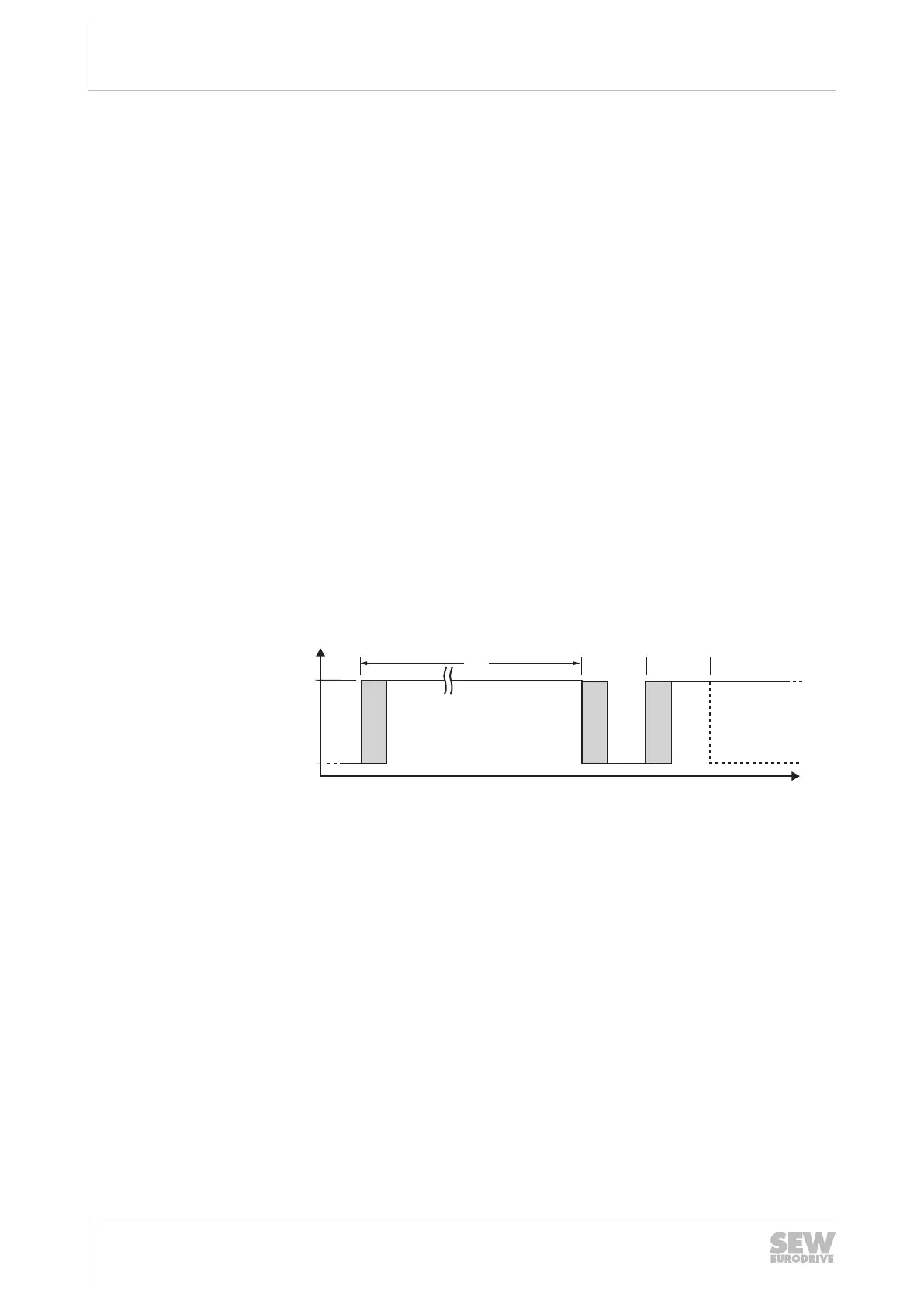

[1]

> 700 ms

> 700 ms

[3]

t

[2] [2] [2]

[4]

15205932683

[1] Maximum 12 months with PL d/SIL2

Maximum 3 months with PL e/SIL3

[2] Internal diagnostics

[3] High: No STO

[4] Low: STO active

• To achieve complete test coverage after a device reset (e.g. after connecting the

line voltage), the test transition (STO active → not active) can only be started >

700ms later. The device signals "ready for operation" or "STO – Safe Torque Off"

if it is not in fault state.

• A detected hardware fault in the internal switch-off channels for STO will lead to a

locking fault state of the application inverter. If the fault is reset (e.g. by switching

the line voltage on/off or by a low level at the STO input for at least 30ms), a com-

plete test with internal diagnostics according to the above mentions test procedure

must be performed. If the fault occurs again, replace the device or contact the

SEW‑EURODRIVE Service.

24748536/EN – 11/2017

Loading...

Loading...