111

8009389/YN39/V3-0/2015-08| SICK OPERATING INSTRUCTIONS|GM35

Subject to change without notice

MAINTENANCE

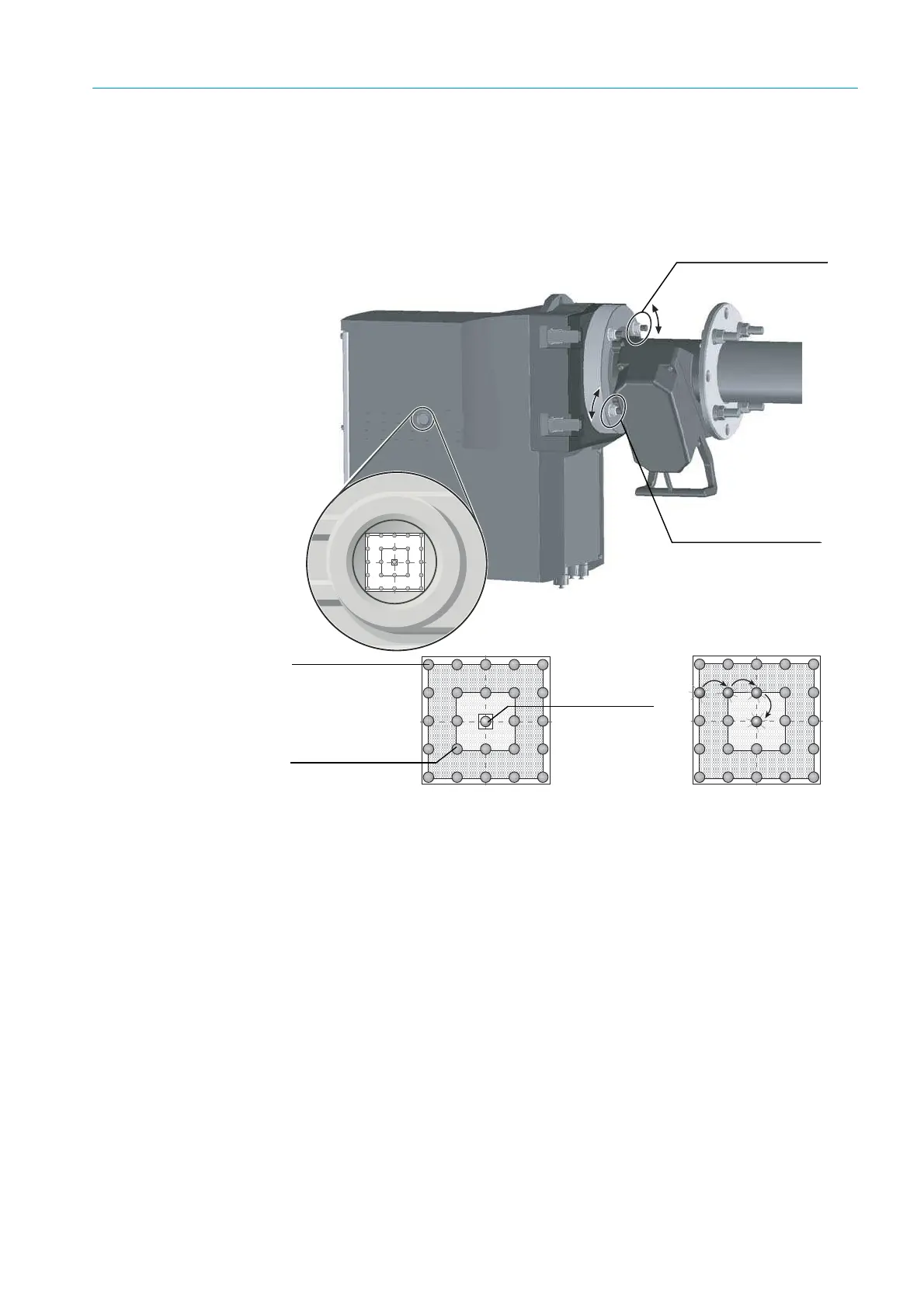

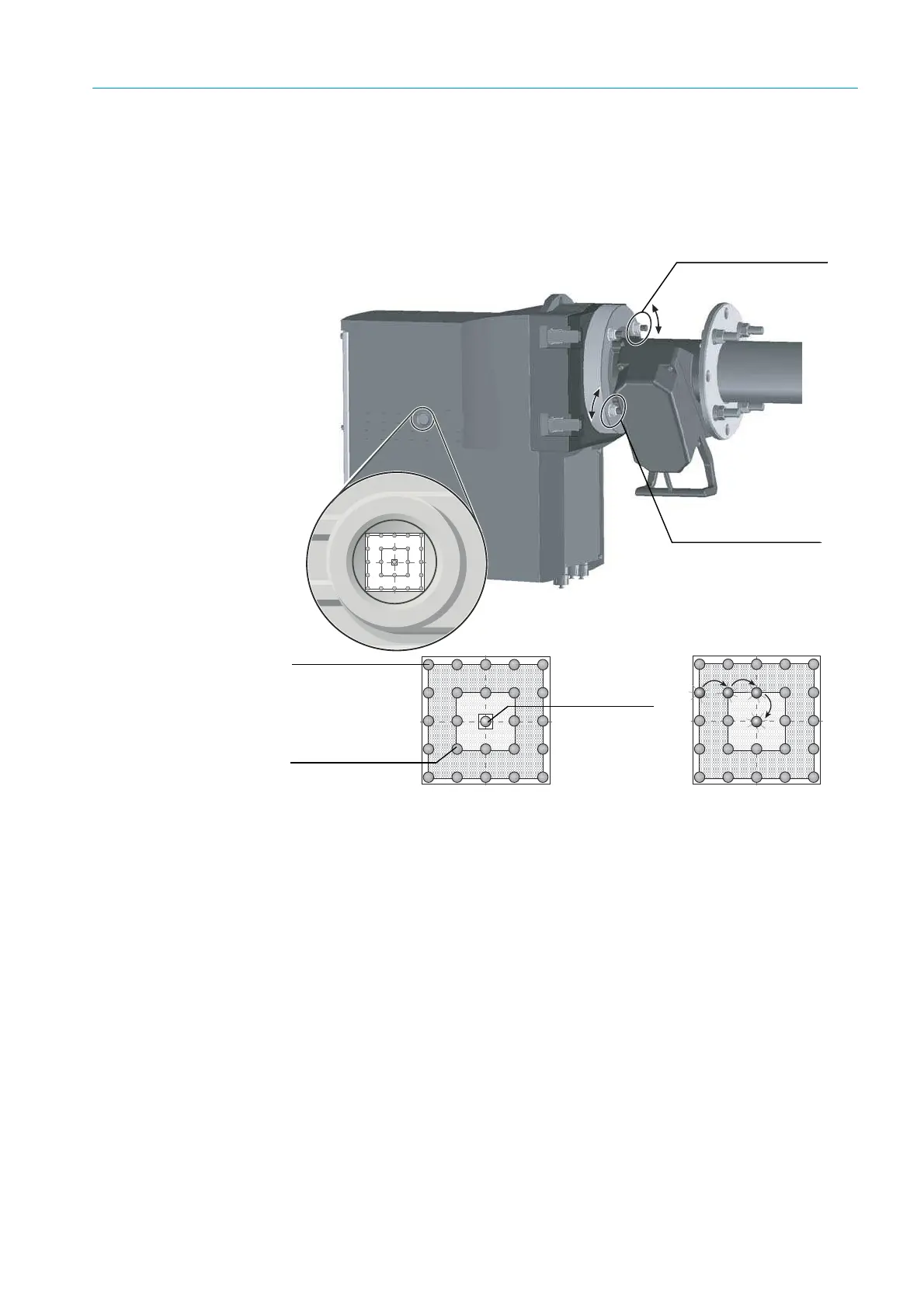

9.5.3 Checking and adjusting the optical alignment of GM35

Check the alignment of the optical axis using the visor on the right-hand side of the SR-unit

enclosure and by making adjustments on the probe fixing on the device flange. The function

“ADJ. OPT. ALIGN” must be activated on systems with automatic alignment,

see “Aligning

the optical axis of the measuring probe”, page 84

.

Fig. 64: Aligning the optical axis

Visor The visor indicates the alignment of the optical axis between the SR-unit and the reflector

in the probe using a 5 x 5 LED matrix. The LEDs light up to represent the position of the light

beam on the reflector at the probe end. The cross hairs show three fields for aligning the

probe.

1 Adjust the optical alignment as shown on

page 111 by adjusting two screws on the

device flange with a 19 mm wrench whilst observing the light position of the LED at the

same time.

2 Horizontal probe adjustment causes the light spot to shift horizontally on the visor and

vertical adjustment causes a vertical shift.

3 Alignment is correct when the lit LED is located within the valid field within the cross

hairs, or is completely within the inner ring marking of the cross hairs.

Note For further information and significance of the LED matrix display on the GM35, see “Check-

ing the EvU display”, page 86

.

Probe adjustment,

horizontal

Probe adjustment,

vertical

Outside the valid

field

Optimum

alignment

Valid field

Loading...

Loading...